Thomas Wasik

Technical Service

0176-11920412

service@jaeger-handling.de

Our Service Offerings

Have we convinced you of the quality and efficiency of our handling solutions? Then, together, we will ensure that this satisfaction remains in the long term – thanks to our optimally adapted service offering. Discover here how we can best support you with customized solutions.

UVV and DGUV Inspections

We carry out both UVV inspections and regular inspections of your electrical systems.

Our expert technicians inspect all safety-relevant components of your systems, machines, and equipment in accordance with the applicable regulations and standards.

Why these inspections are important:

- Legal Security: The inspections ensure that your company complies with regulations to minimize liability risks.

- Prevention of Failures: Regular inspections prevent technical failures and extend the service life of your machines.

- Employee Protection: Safe systems minimize the risk of accidents for your employees.

- Documentation and Proof: We provide you with comprehensive documentation for your inspections, which you can submit if required.

UVV Inspection

We offer professional UVV inspections for your systems in accordance with the applicable accident prevention regulations (DGUV). Our qualified experts check your lifting aids, manipulators, and other handling equipment for safety, functionality, and wear to prevent accidents and meet legal requirements.

After passing the inspection, you will receive an inspection sticker and detailed documentation of the current condition of your system.

DGUV Inspection

In accordance with DGUV V3, we carry out regular inspections of your electrical systems.

We ensure that the inspections of systems, machines, and equipment are carried out in accordance with the applicable regulations and standards to ensure maximum safety and reliability.

Our expert technicians document each inspection in detail and are always available to provide advice.

Preventive Maintenance

Our service technicians carry out maintenance on site and document all measures in detail. Wear parts with a risk of failure are identified and listed. On request, you will receive an offer for replacement or repair.

We also optimize your systems to extend their service life and minimize downtime.

Advantages

- Ensure Operational Capability: Regular inspections ensure that your system is always ready for use, which prevents unexpected failures and ensures smooth production.

- Save Costs: Early problem detection helps to avoid expensive emergency repairs and downtime, which leads to significant savings in the long term.

- Increase Performance: Regular interventions optimize the performance of your systems, which increases both productivity and reduces energy consumption.

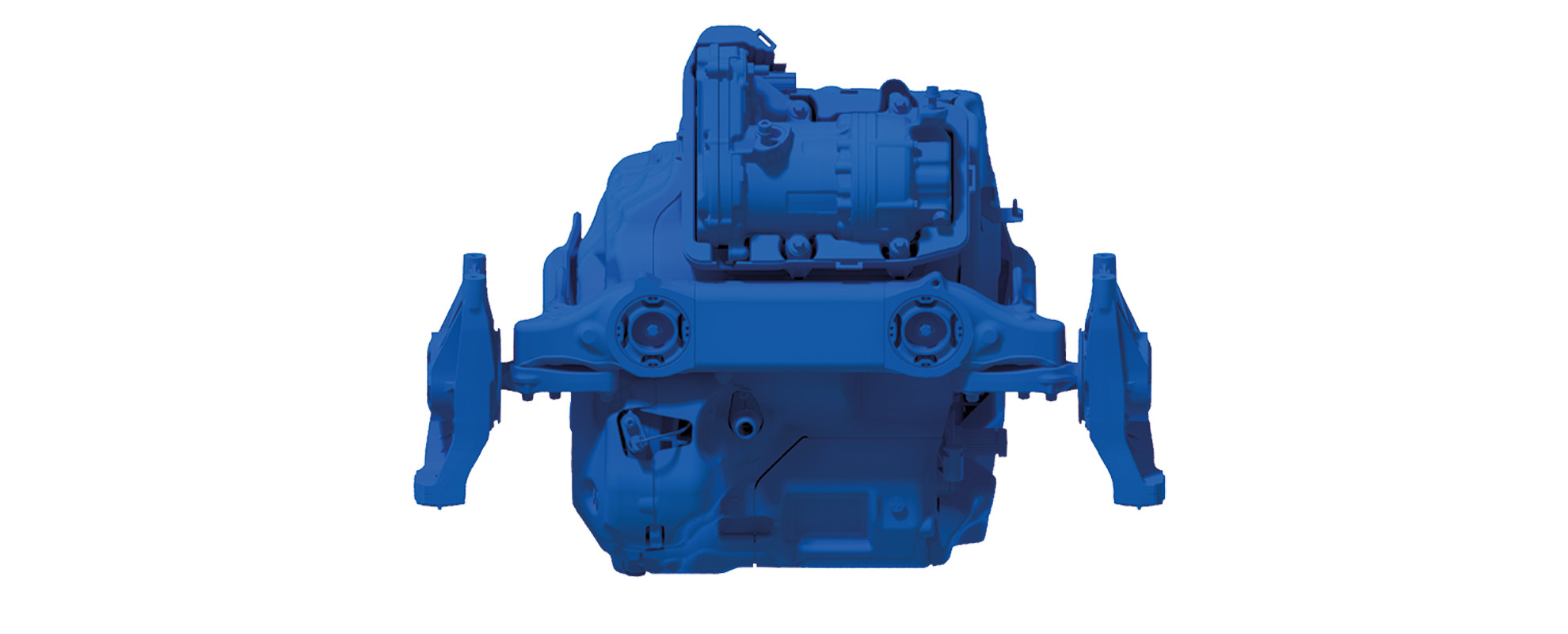

Repair and Maintenance

We offer you a flexible and cost-optimized repair service to quickly restore the function of your equipment. Our service staff will advise you on whether the repair should be carried out on site or in our company – according to your needs.

In addition, we ensure that your equipment always remains in perfect condition. Through maintenance work in cyclic exchange or during planned operational interruptions, we maximize the service life of your equipment and prevent unexpected failures.

Advantages

- Cost Efficiency: Thanks to targeted repairs, you only pay for what is necessary.

- Service Life Extension: Regular maintenance protects your jh-products and minimizes failures.

- Flexibility: Repair options on site or in our company.

- Efficiency Increase: Individual maintenance services reduce downtimes.

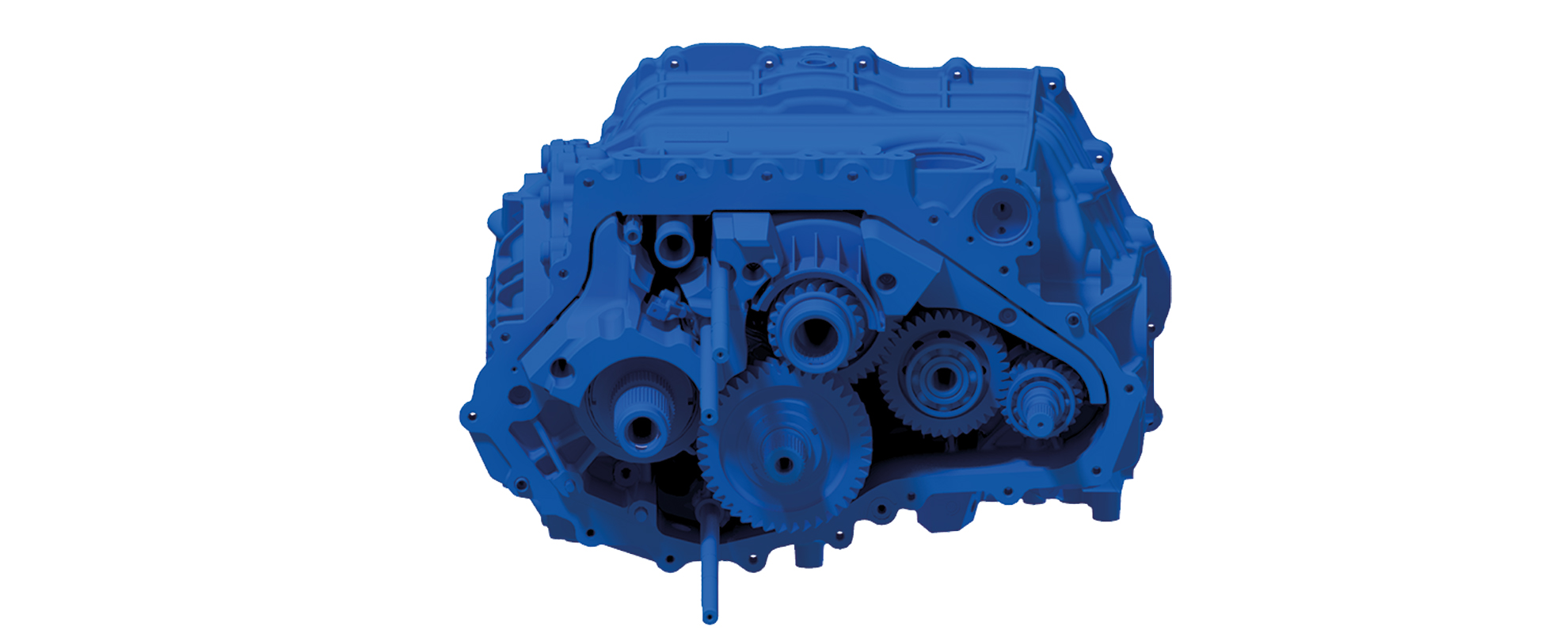

Spare Parts and Component Management

We guarantee you original wear and spare parts in manufacturer quality at the best conditions.

Thanks to our well-structured warehousing, we can deliver the required spare parts and components within a very short time so that your machines and systems are quickly ready for operation again.

Advantages

- Maximum Operational Readiness: By quickly accessing spare parts, you minimize downtimes and ensure high availability of your systems.

- Cost Efficiency: Original spare parts at the best conditions help you to save costs without compromising on quality.

- Reliability: Our high-quality spare parts guarantee a long service life and reliable performance of your equipment.

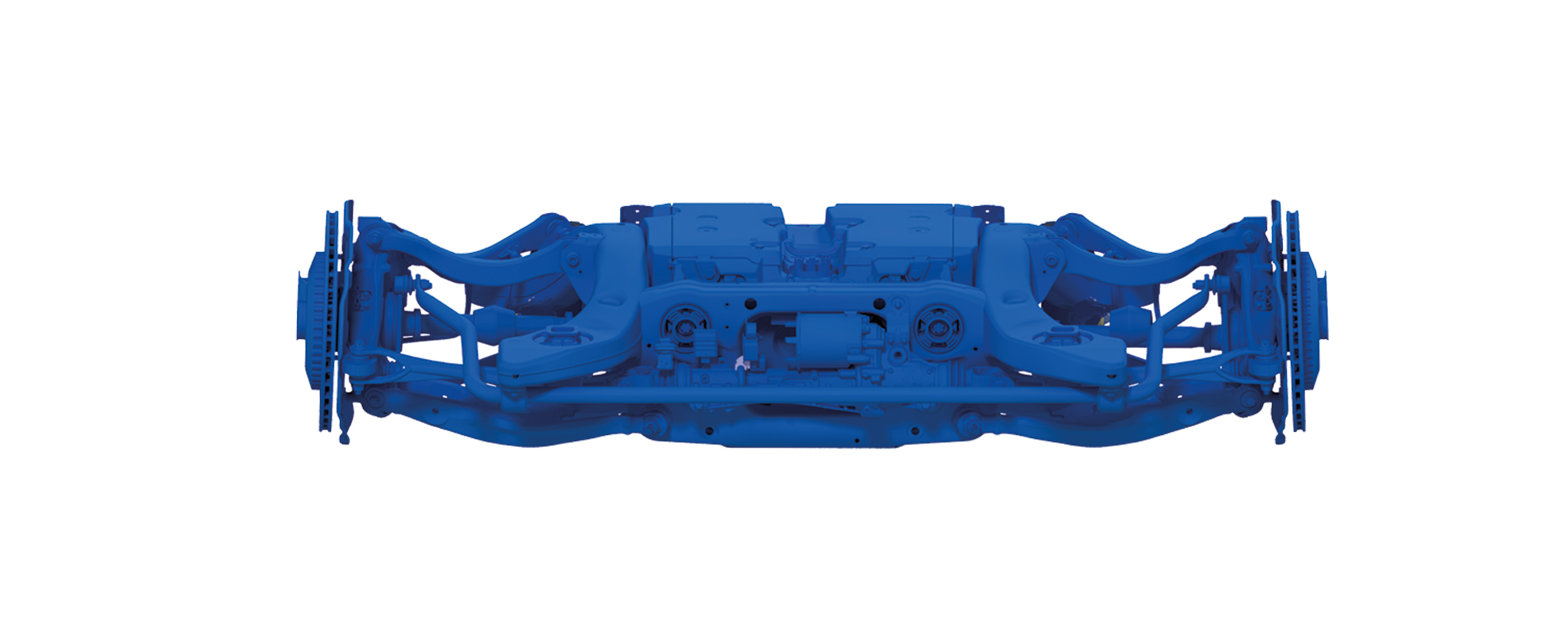

Relocation

We support you in relocating your screwing systems from the initial assessment to successful commissioning at the new location.

With careful disassembly, safe transport, and professional assembly, we ensure that your systems can be put back into operation quickly and reliably.

Our experienced technicians accompany you throughout the entire process and ensure a smooth procedure.

After completion, you will receive complete documentation of the work carried out so that you always have an overview of the condition and changes to your systems.

Services and Advantages

- On-site Assessment: Together with you, we coordinate the schedule, technical planning, and implementation to ensure a smooth process.

- Disassembly & Relocation: Mechanical and electrotechnical disassembly, transport, and careful assembly at the new location.

- Commissioning & Production Start: Our trained service personnel will support you mechanically and electrotechnically for the start of production.

- Final Documentation: Upon completion, you will receive a fully revised documentation from us.

- Efficient Implementation: Minimizes downtimes and production interruptions.

- Professional Support: Our trained service personnel will accompany you throughout the entire process.

Training Courses

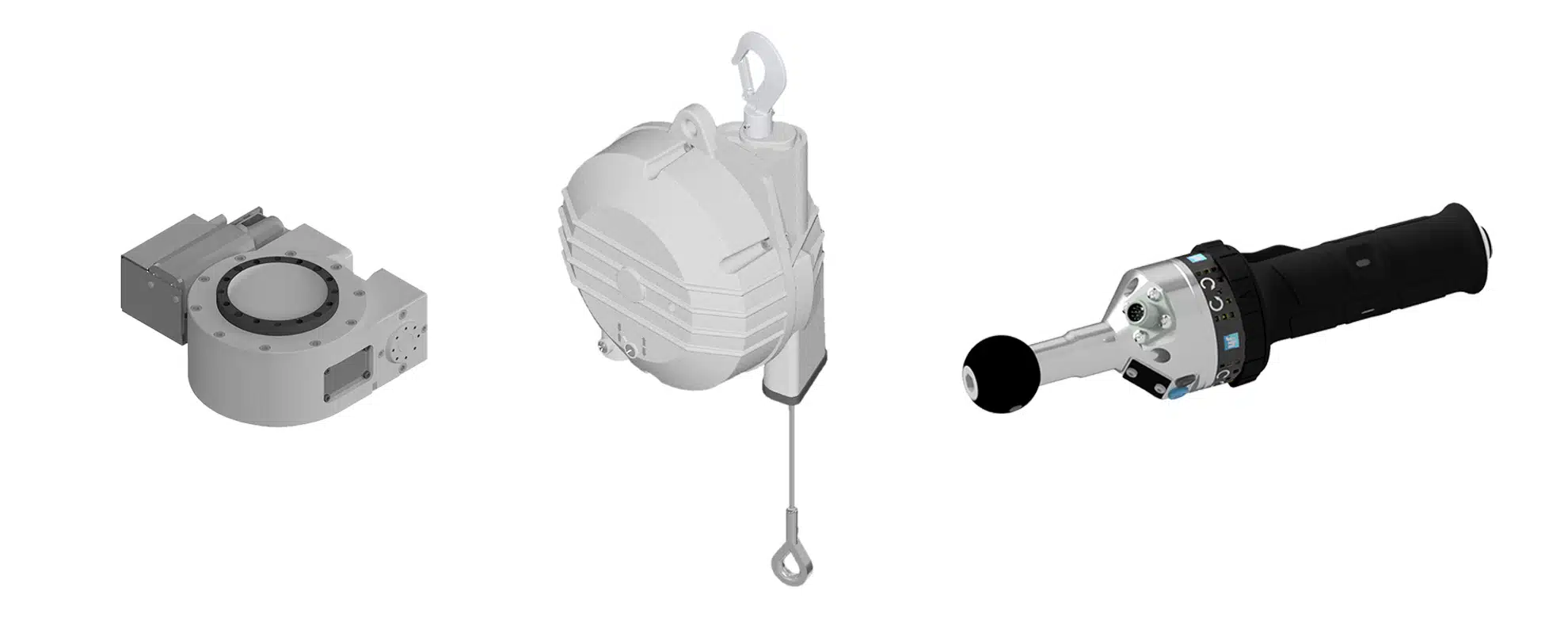

We offer training courses for your employees to optimize the handling and application of our jh-products such as drives, handles and balancers.

With customized training courses that include both theoretical basics and practical exercises, we increase efficiency and safety in handling the equipment.

This enables your employees to work even more effectively and sustainably increase the productivity of your company.

Advantages

- More Efficient Working Method: Employees work more productively and solve problems independently.

- Increased Safety: Correct application reduces the risk of accidents.

- Increase in Productivity: Well-trained employees work faster and more effectively.

- Fewer Downtimes: Training courses avoid sources of error and increase operational readiness.