Welcome to the world of component handling. Here you will find an overview of our various products. Each individual handling system can be found in a wide variety of applications and is a great support in the field of handling.

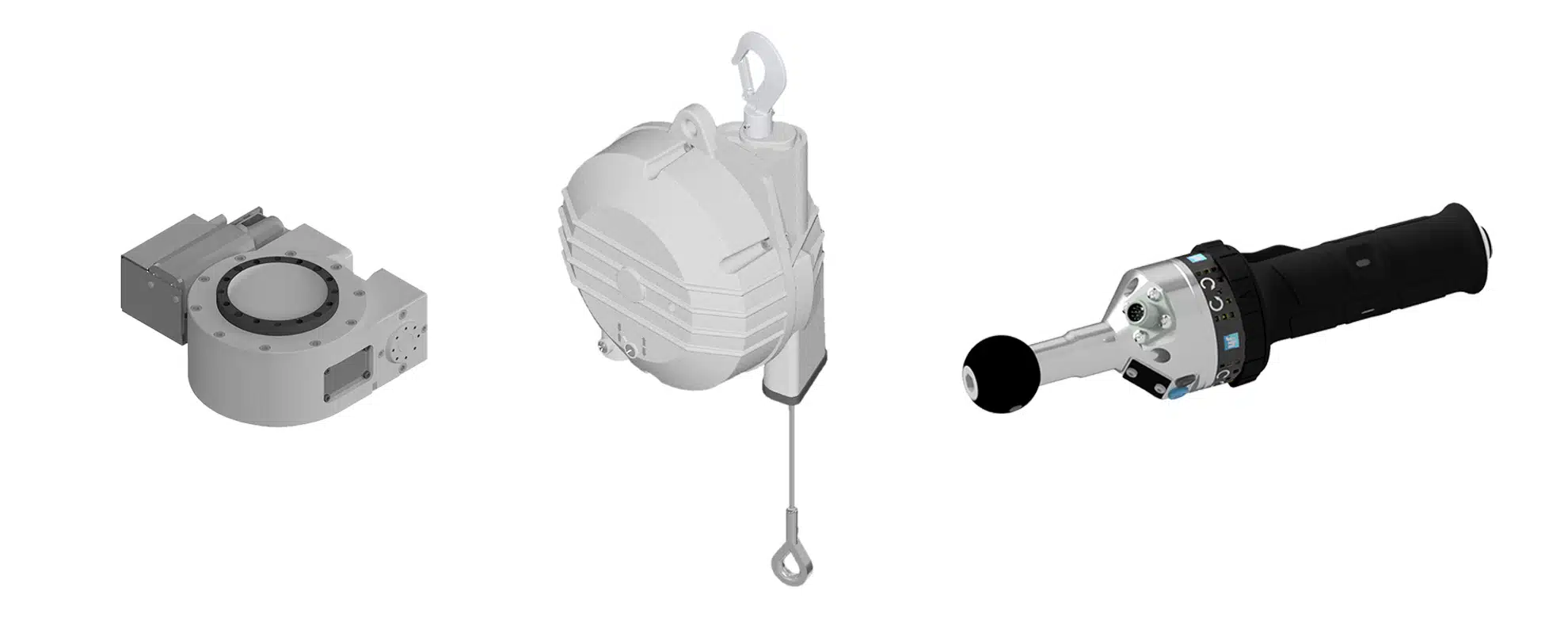

Adaptation Systems

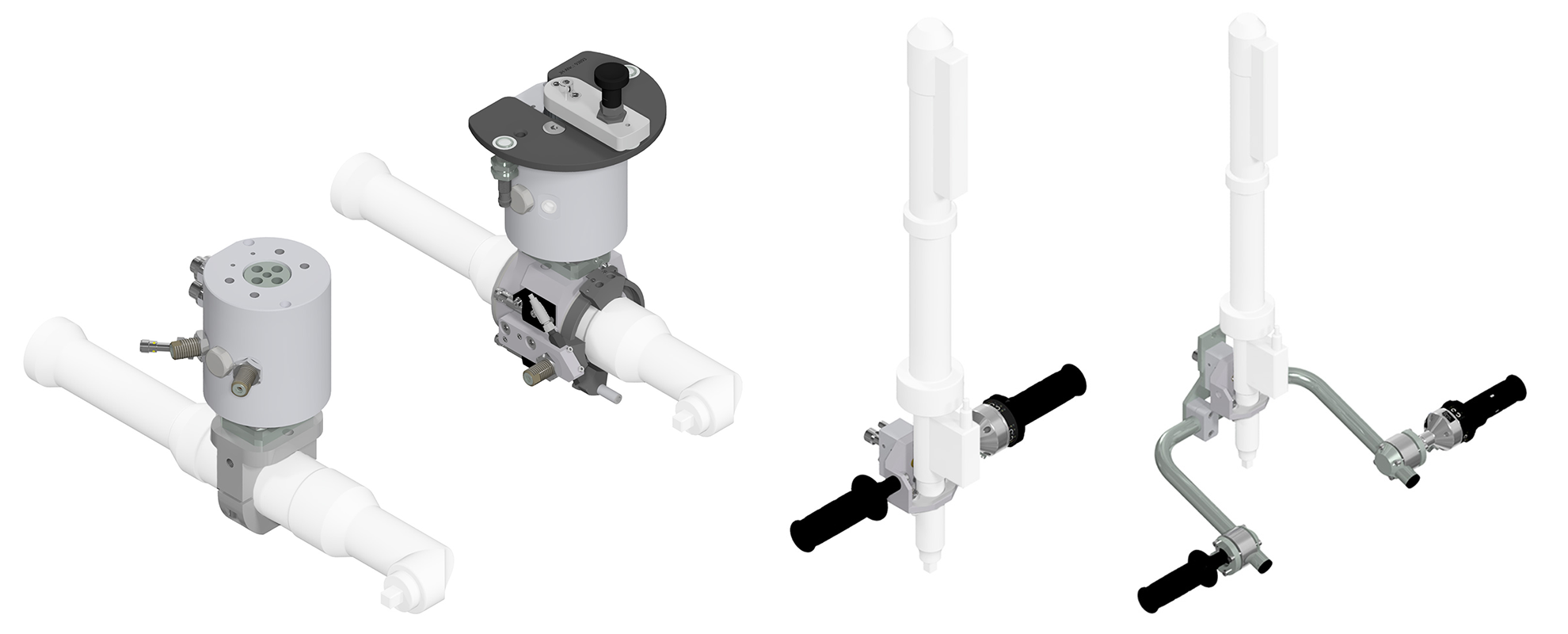

Our DEMA and DEVA units are specialized rotary units used in industrial applications for the precise positioning and rotation of tools or components.

Properties

Max. torque absorption: 500Nm

Rigid and rotatable tool holders

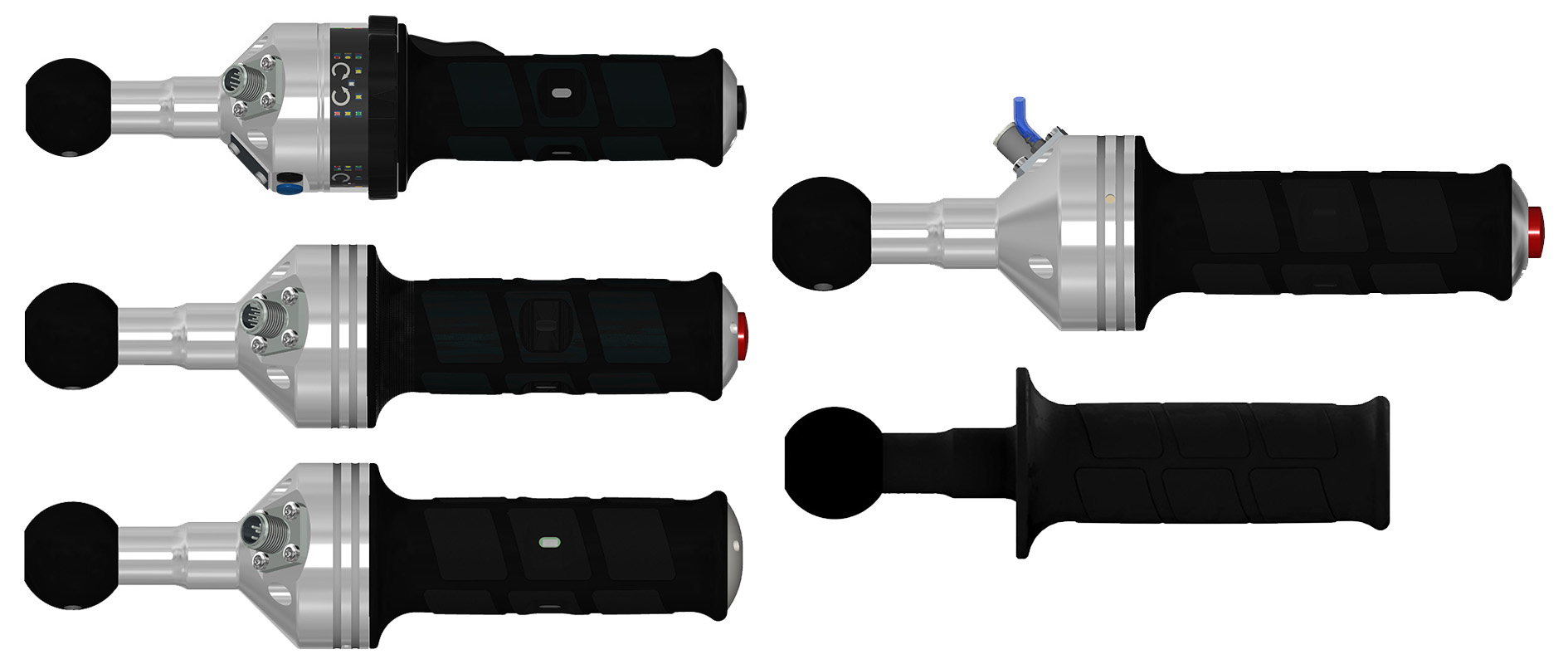

Control Handles

Welcome to the world of ergonomic control handles. These versatile handles serve as an interface between humans and machines, combining state-of-the-art technology with intuitive design to facilitate the operation of machines and tools in industrial assembly. Whether in automotive manufacturing, electronics production or other industries – our control handles offer a wide range of applications that increase efficiency and reduce the workload for employees.

Properties

Max. output torque: 650Nm

High variability due to ball connection

IO-Link-enabled control handles

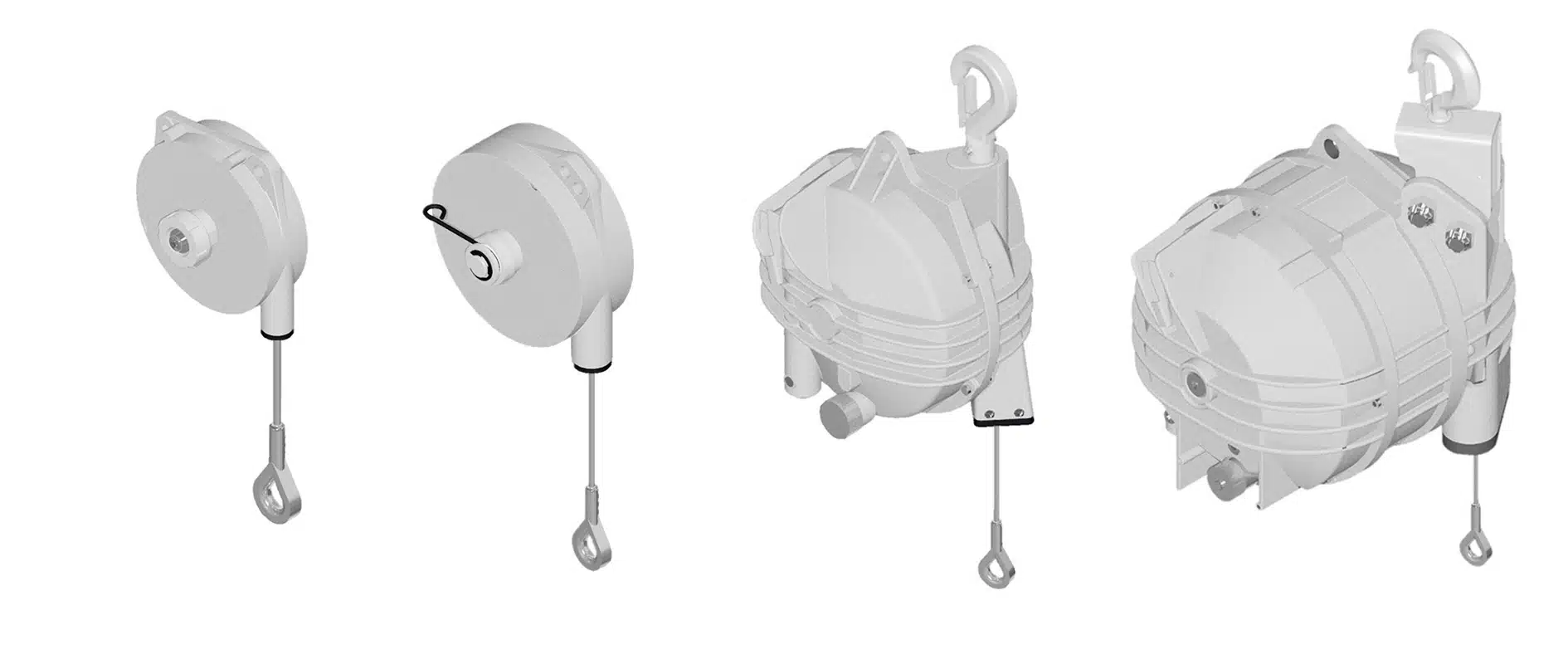

Spring Balancers

In industrial assembly technology, especially for hand-held and hand-guided tools and equipment, spring balancers play a crucial role. They ensure precise weight compensation and improve handling, which significantly improves ergonomics, safety and efficiency in the workplace.

Spring balancers are designed exclusively for handling static loads and cannot be used for dynamic loads.

Properties

Max. load capacity: 180Nm

Flexible stroke height adjustment

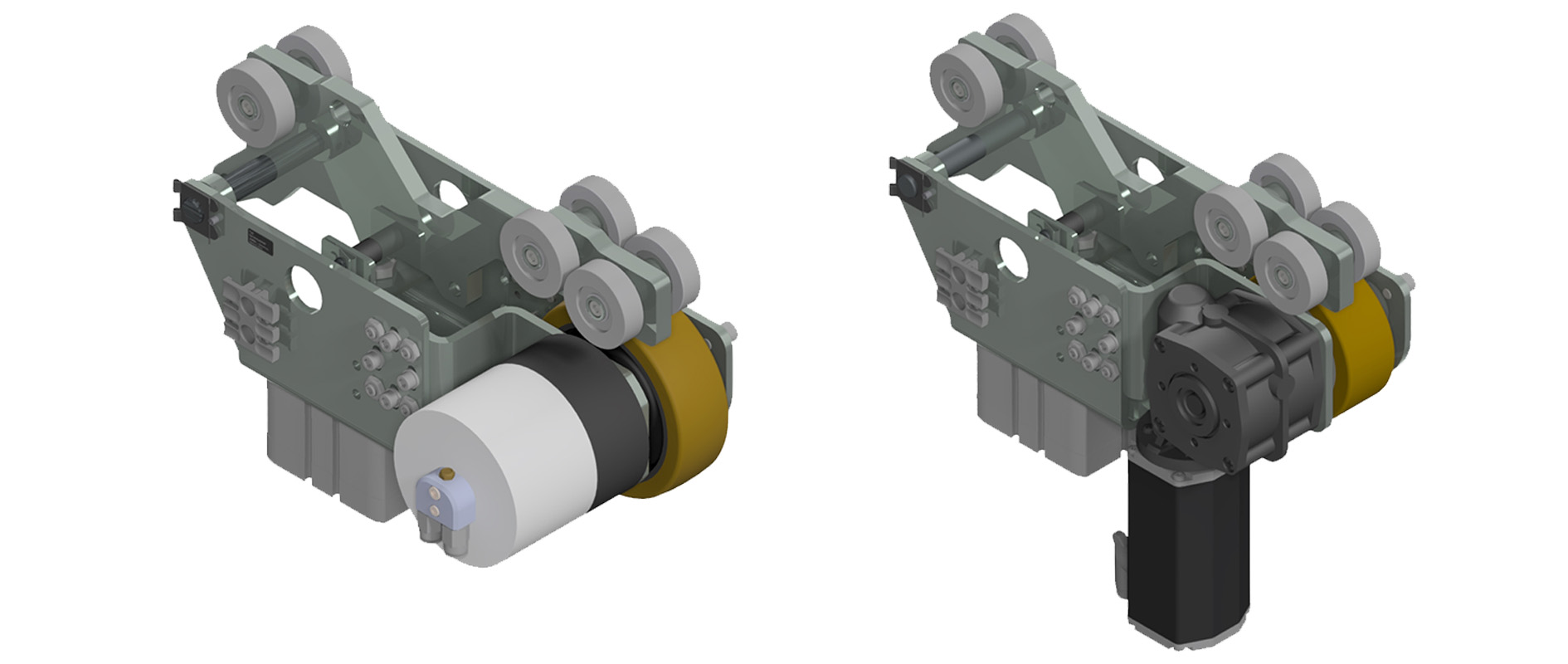

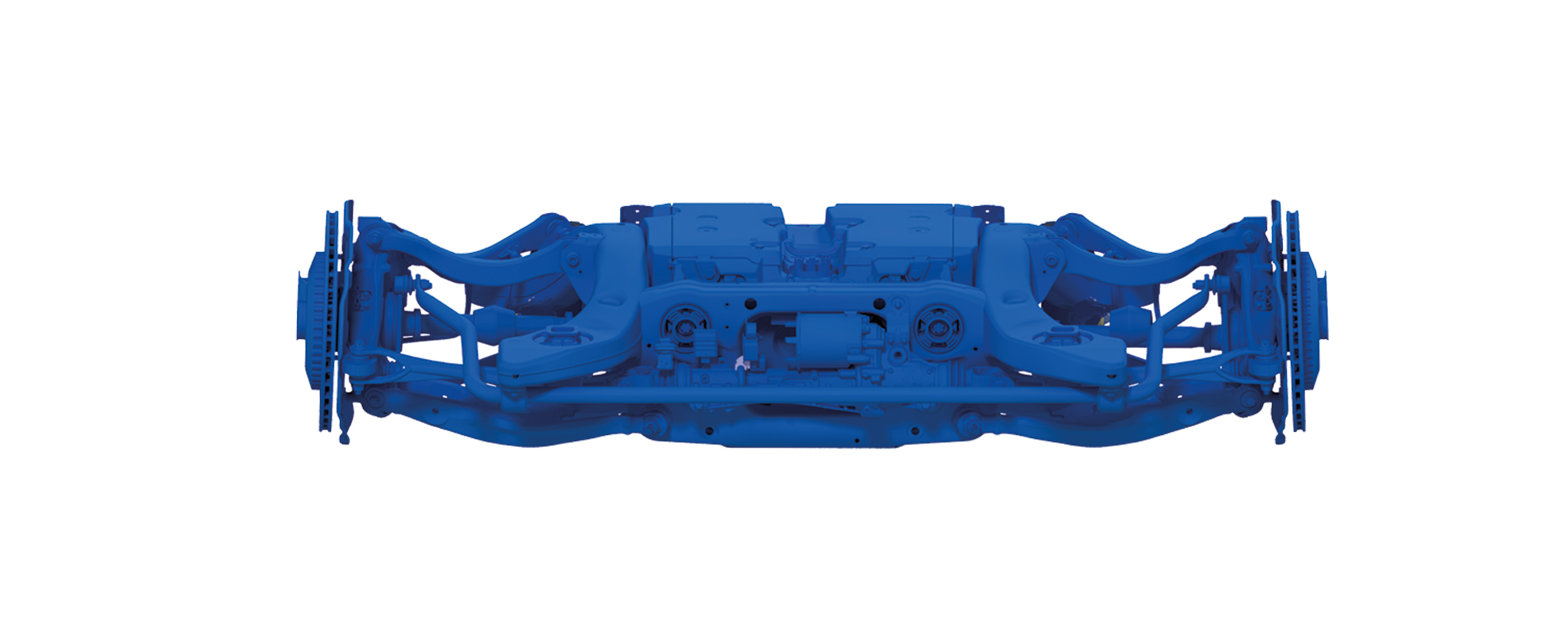

Friction wheel drives

The friction wheel drive is a drive system in which power is transmitted through friction between two surfaces. Since this technology is a very efficient and reliable solution for moving and handling loads, the friction wheel drive is frequently found in a wide variety of industrial applications. The precise control and flexible adaptation enable use for a wide variety of requirements in modern production environments.

Properties

Propulsion force: 250N

Maximum mass: 600kg

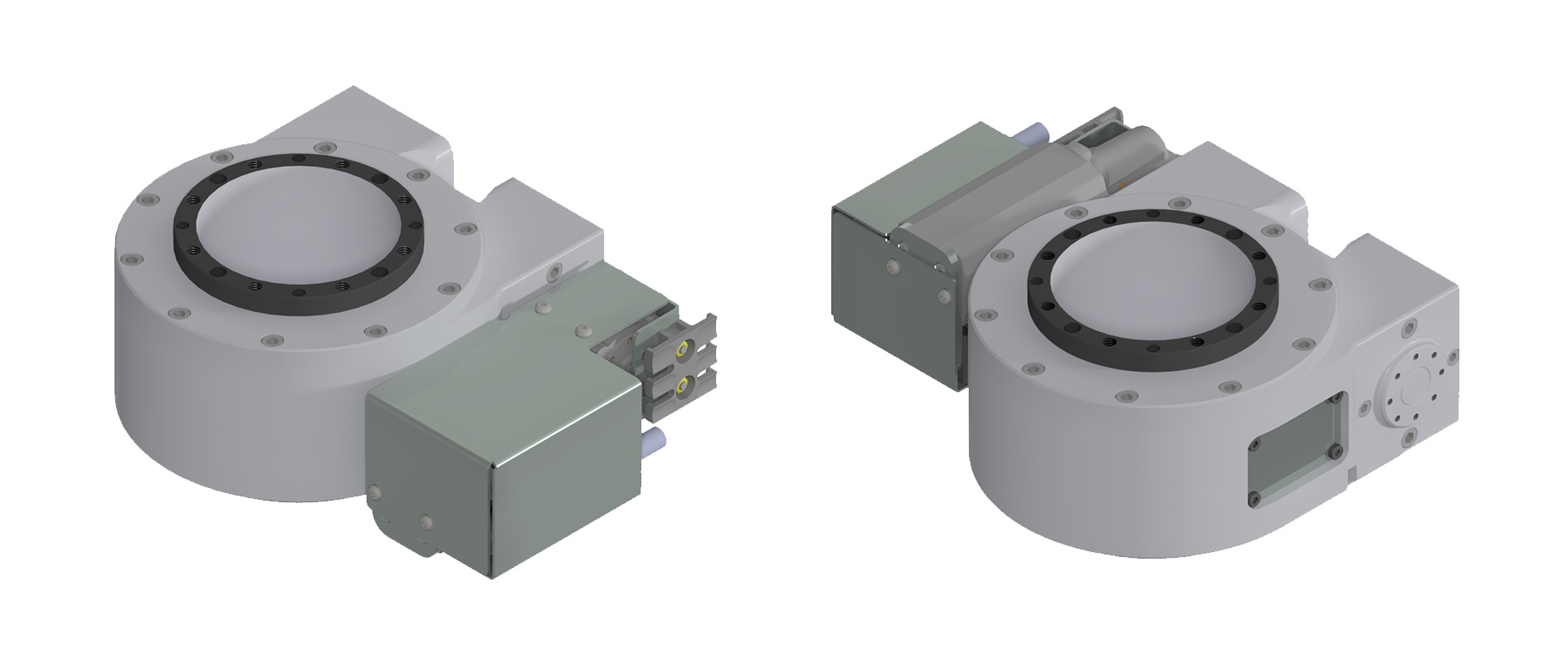

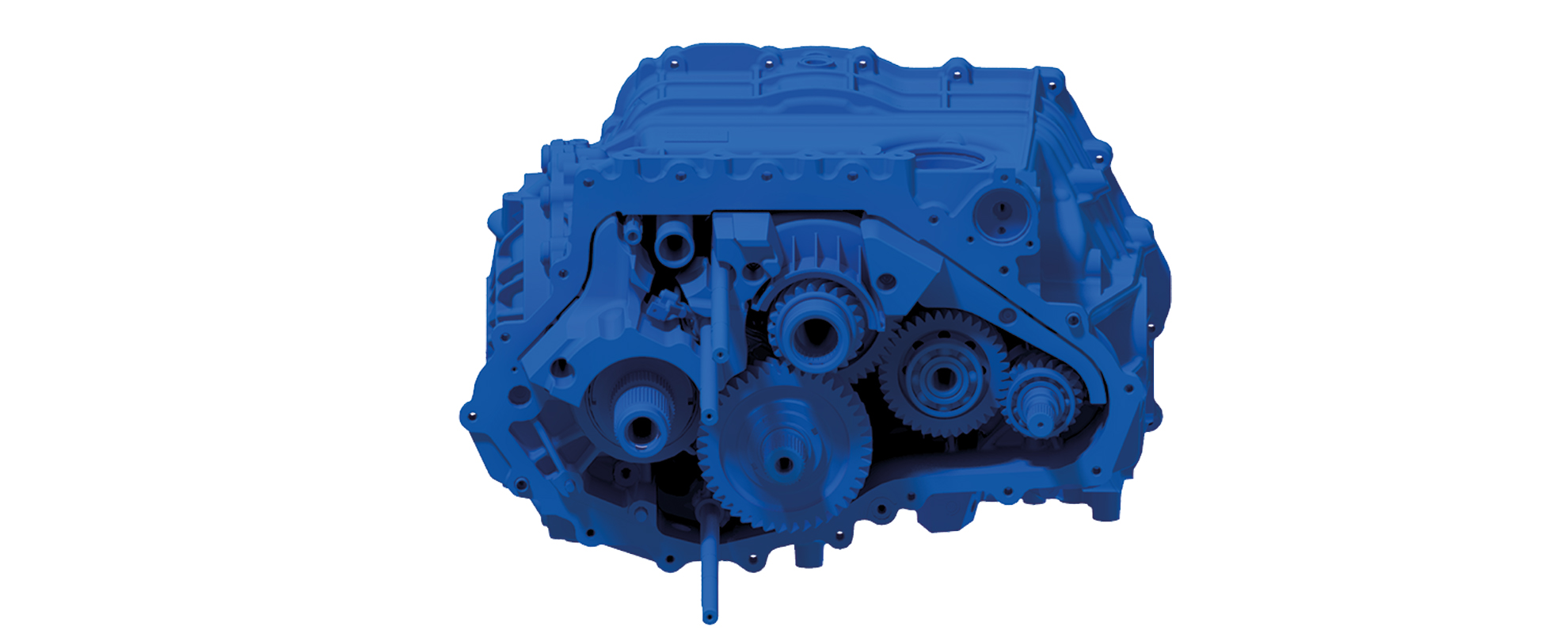

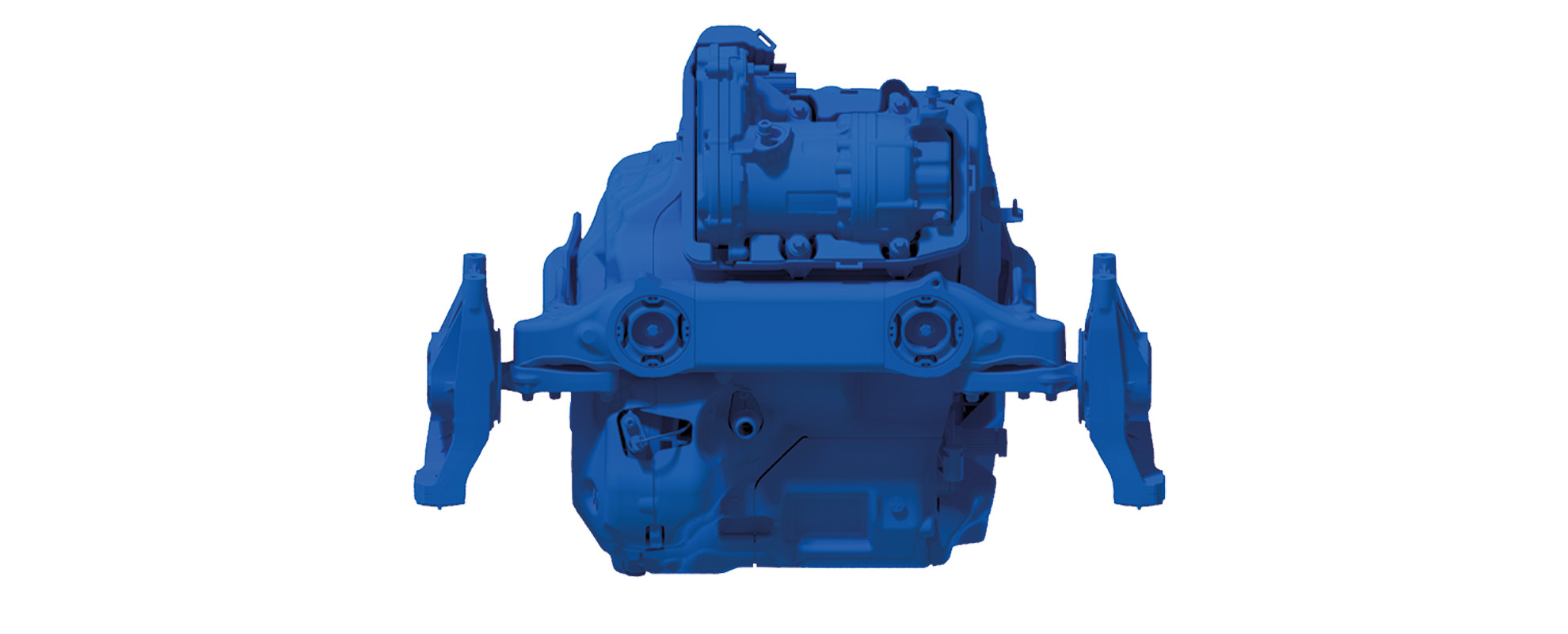

Electric rotary actuators

High precision, efficiency and reliability: These three keywords describe an electric rotary actuator from JÄGER Handling very well. These rotary actuators enable precise and repeatable movements for a wide variety of industrial applications in conjunction with hand screwdrivers or screw spindles. In addition, the rotary actuators can be combined with each other to achieve even greater flexibility.

Properties

Max. output torque: 650Nm

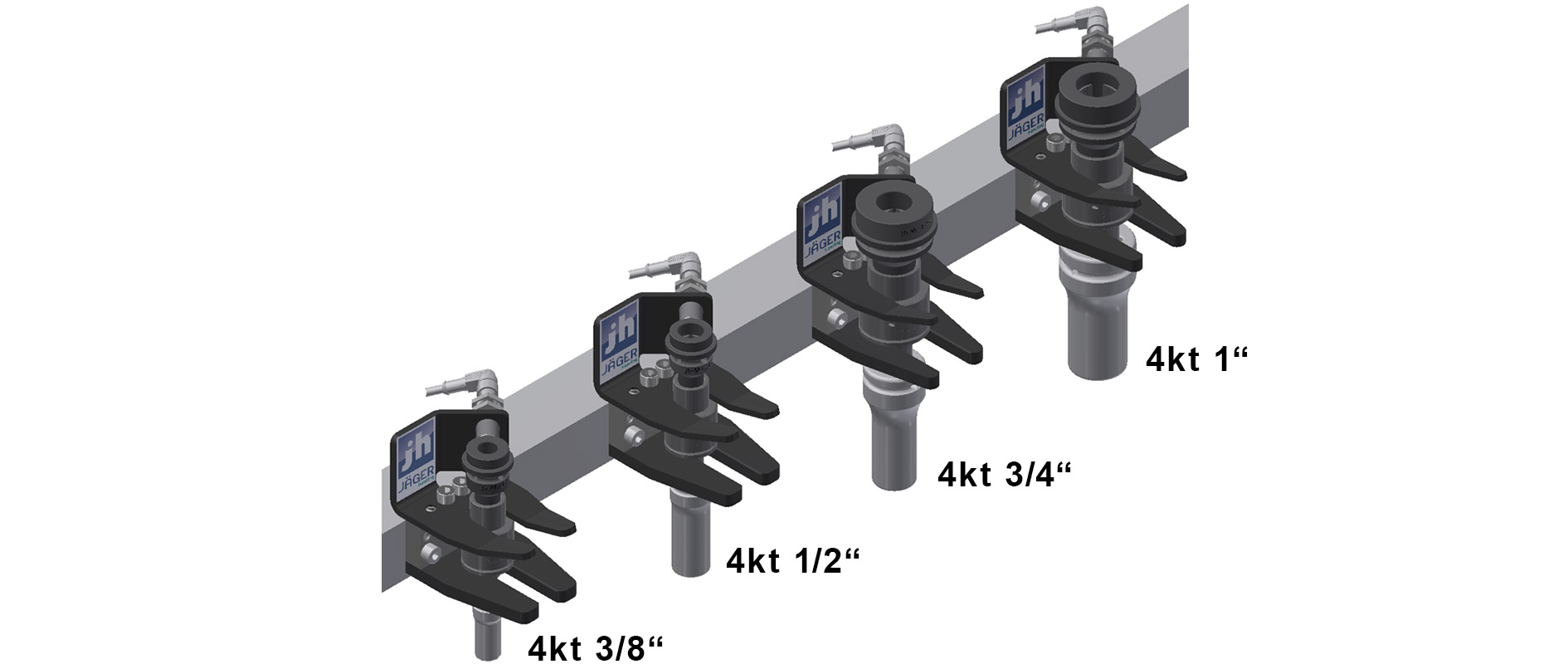

speedy socket changer

The speedy socket changer is a product specially developed by JÄGER Handling. It enables the automatic changing of sockets by a robot, which, in combination with a quick-change chuck and an adapter, removes the sockets from the holder. Confusion is ruled out by querying sensors in the holder. In the blue section you will find the video on the exact application.

Properties

Diameter: up to 55mm

Max. torque: 1000Nm

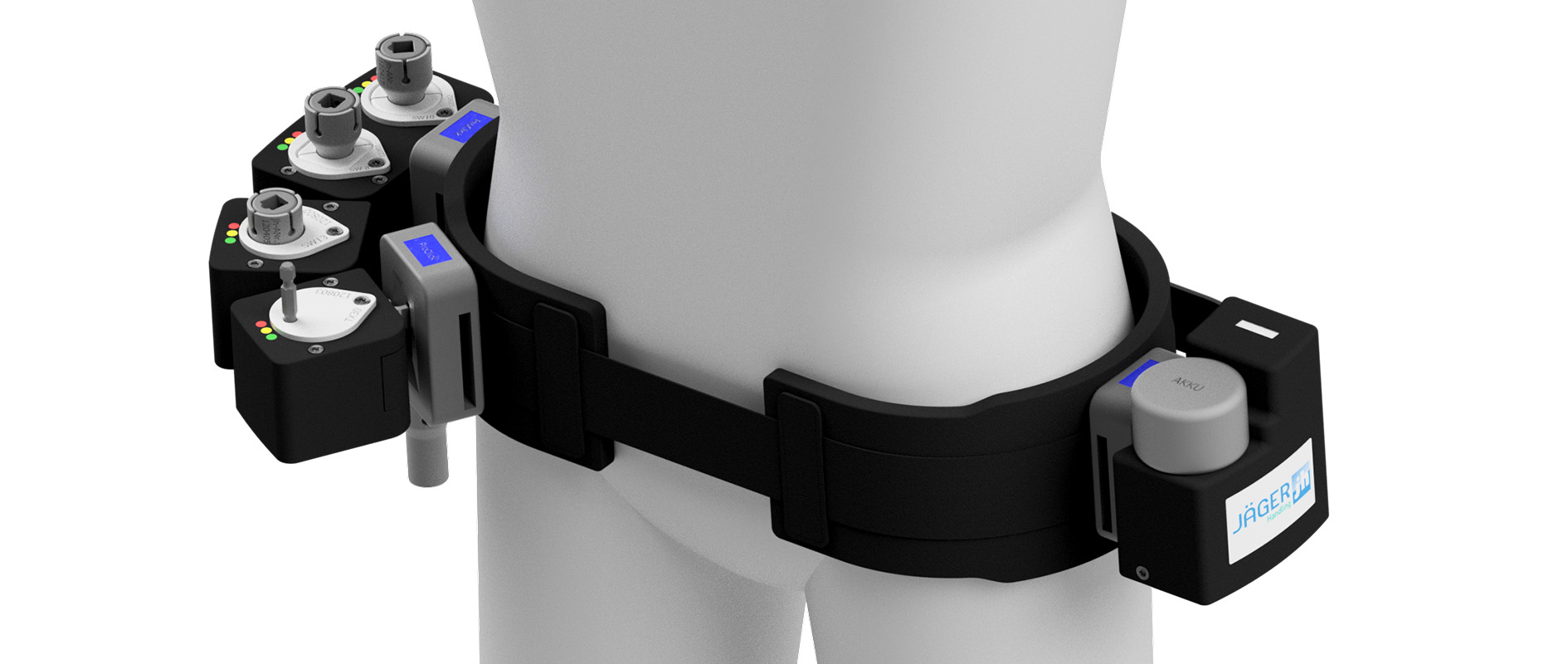

Socket quiver

The socket-belt is a portable socket quiver that has been specially developed for flexible use in industrial assembly. It communicates wirelessly, transmits the data cyclically via WiFi and is equipped with a 12V battery. Separate slots allow the accommodation of several screwdriving tools. Each tool slot is equipped with three colored LEDs (red, yellow, green) that indicate the current status or process steps.

Properties

Max. outer diameter: 34mm

Max. tool length: 290mm