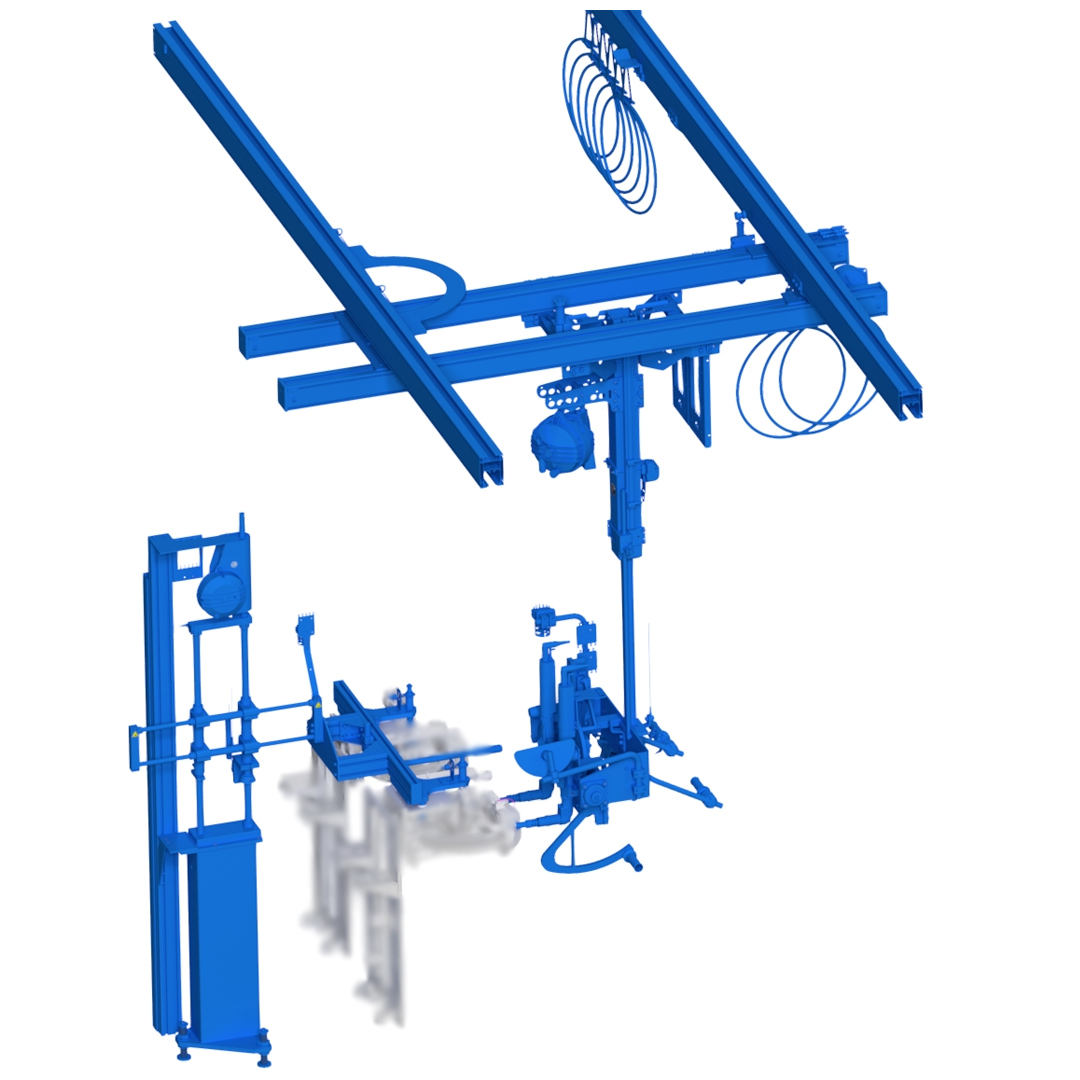

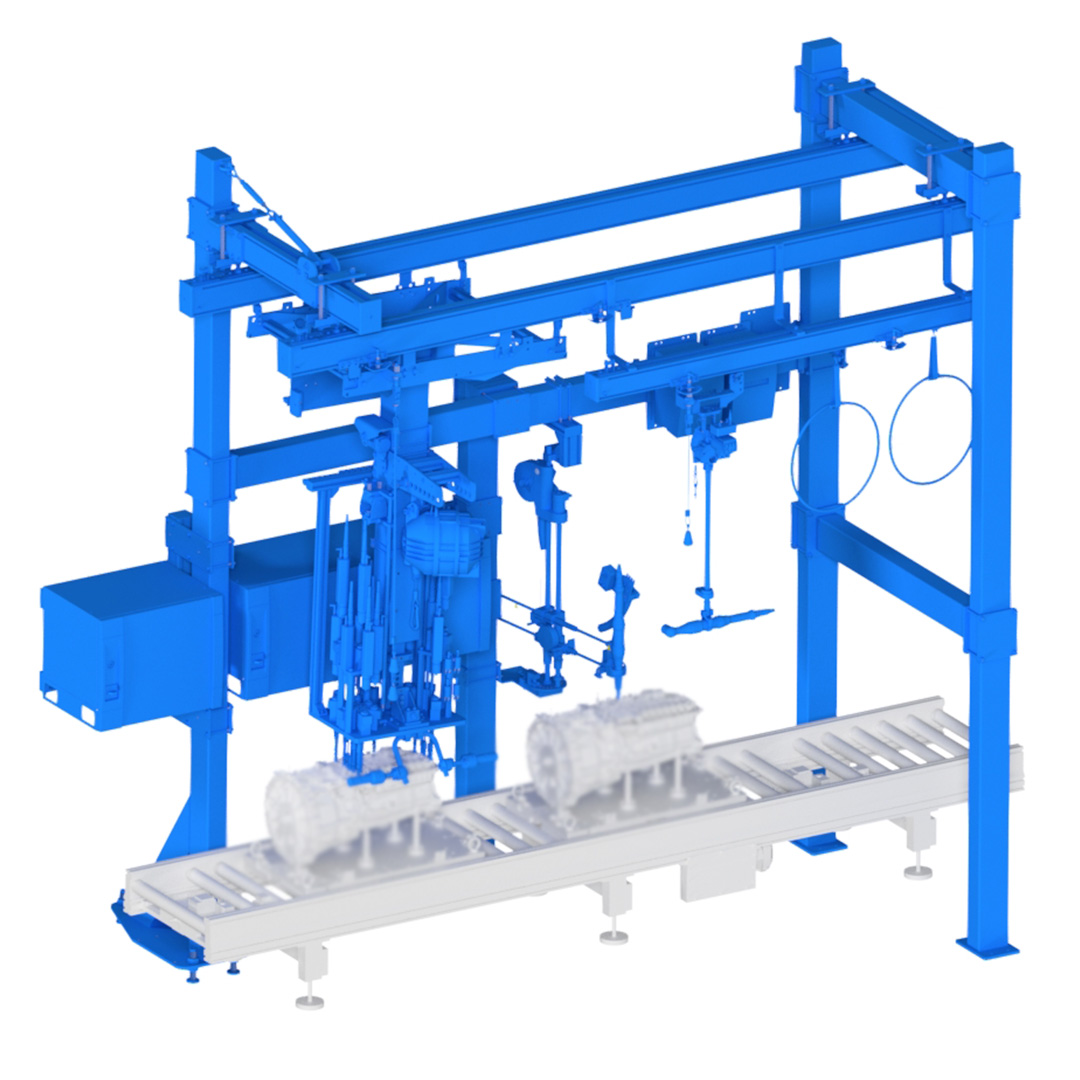

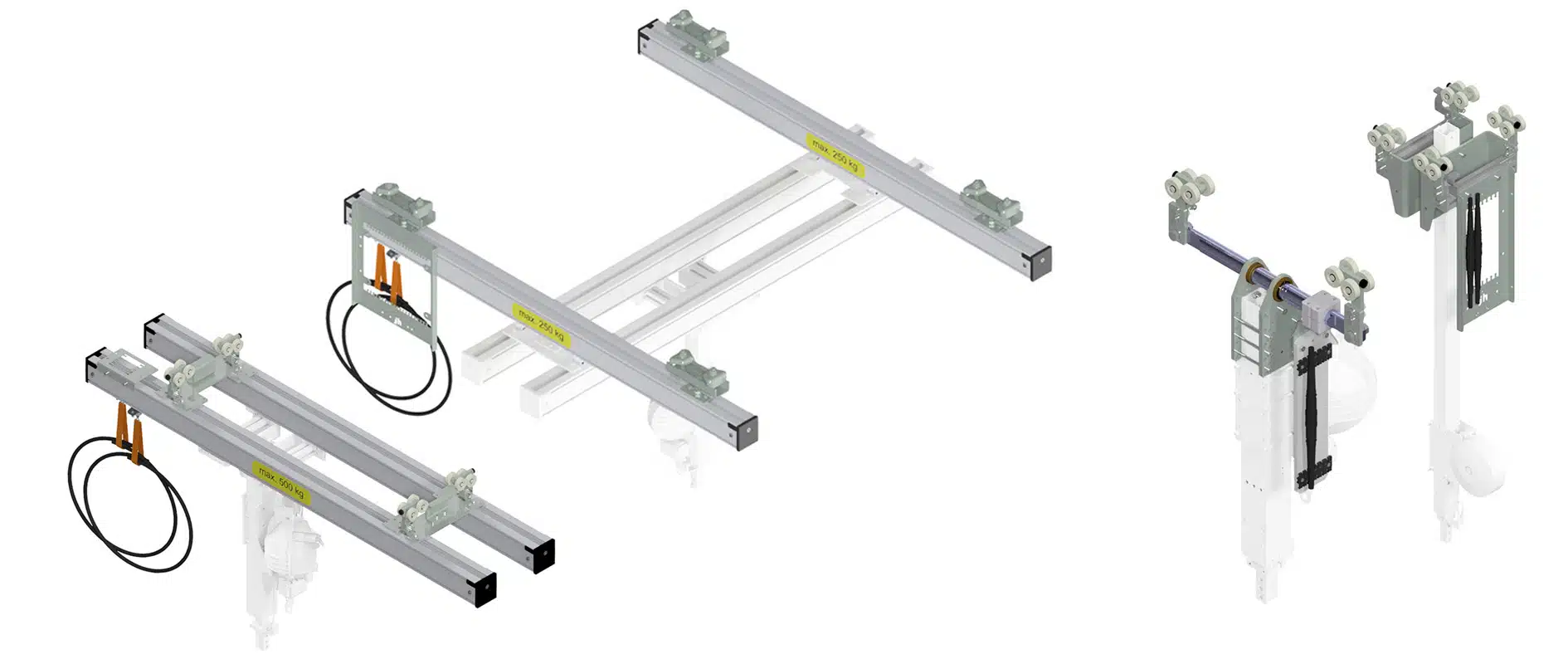

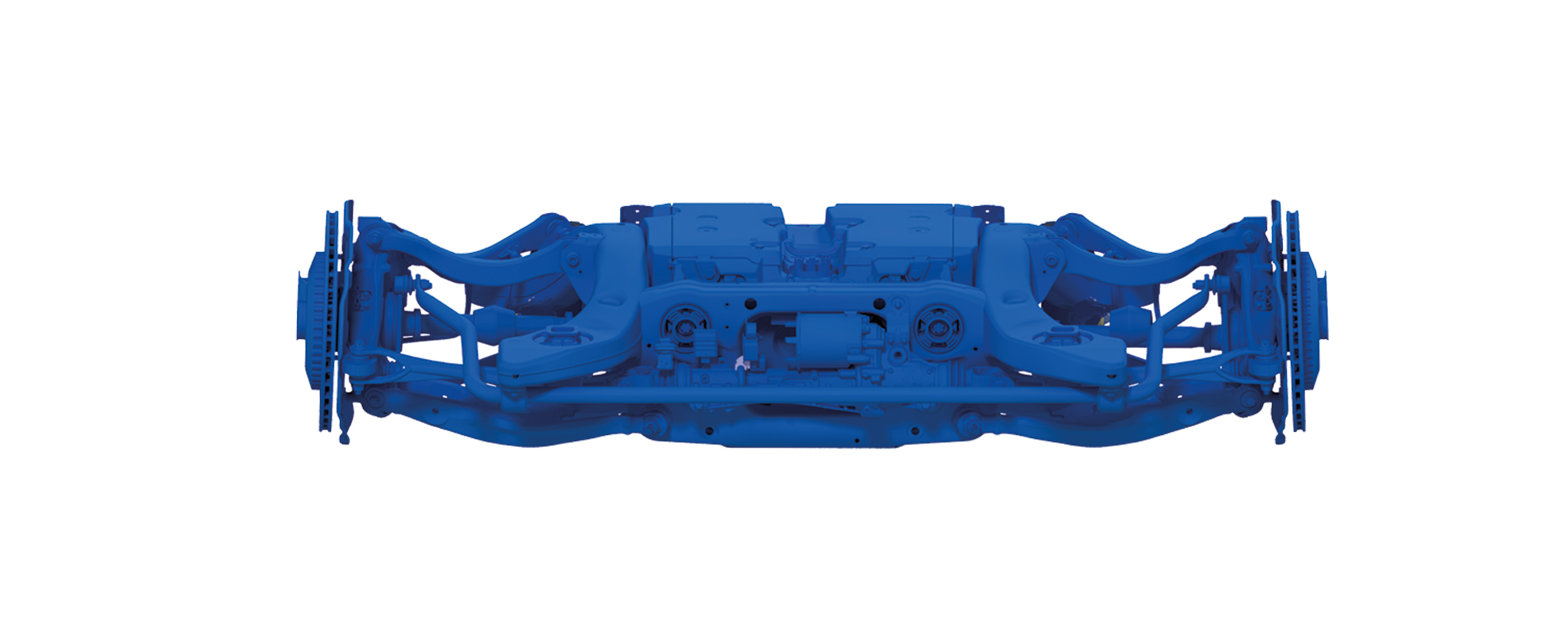

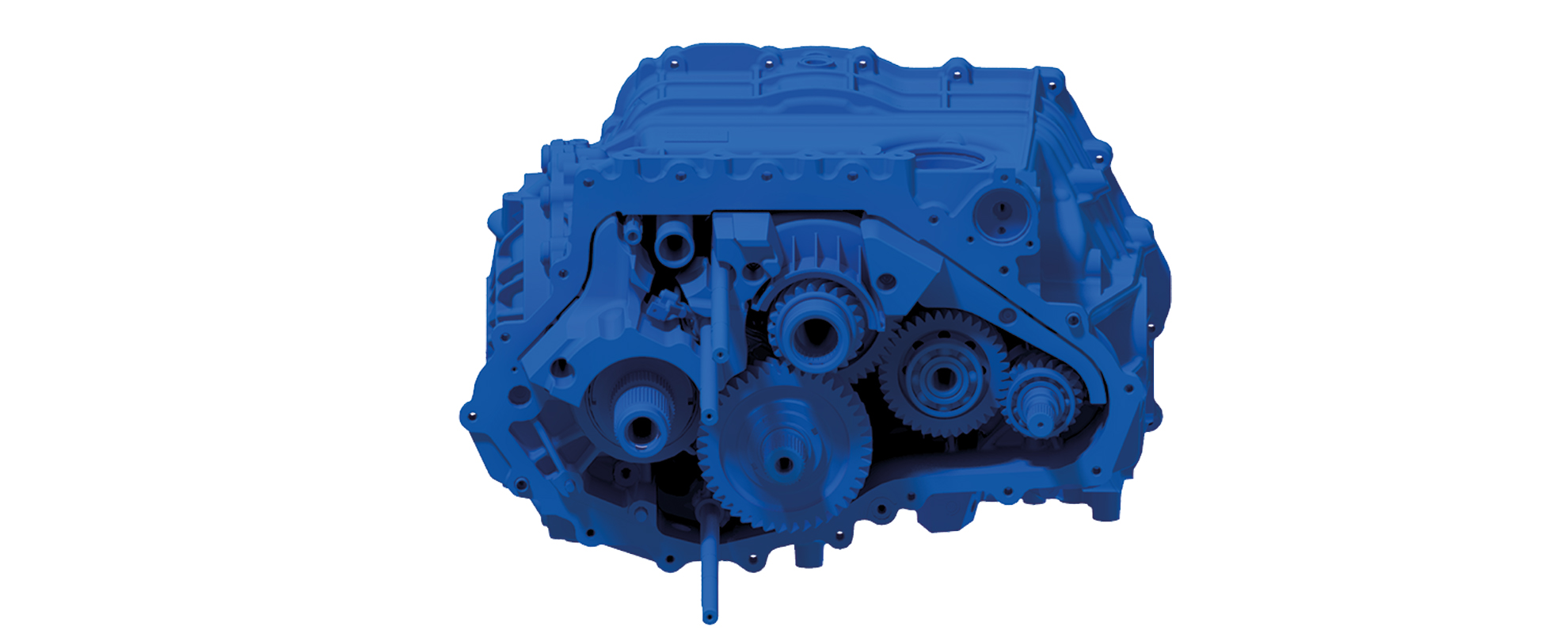

The handy-lift modular system is used in combination with the eepos rail system in individual workstations as well as in linked cycle and flow assembly lines with automatic workpiece transfer, and offers systems for load capacities up to 500 kg and torques up to 1500 Nm. Partially automated versions for single- or multi-spindle screwdriving increase productivity by eliminating non-value-added activities and noticeably reduce costs.

Configurations

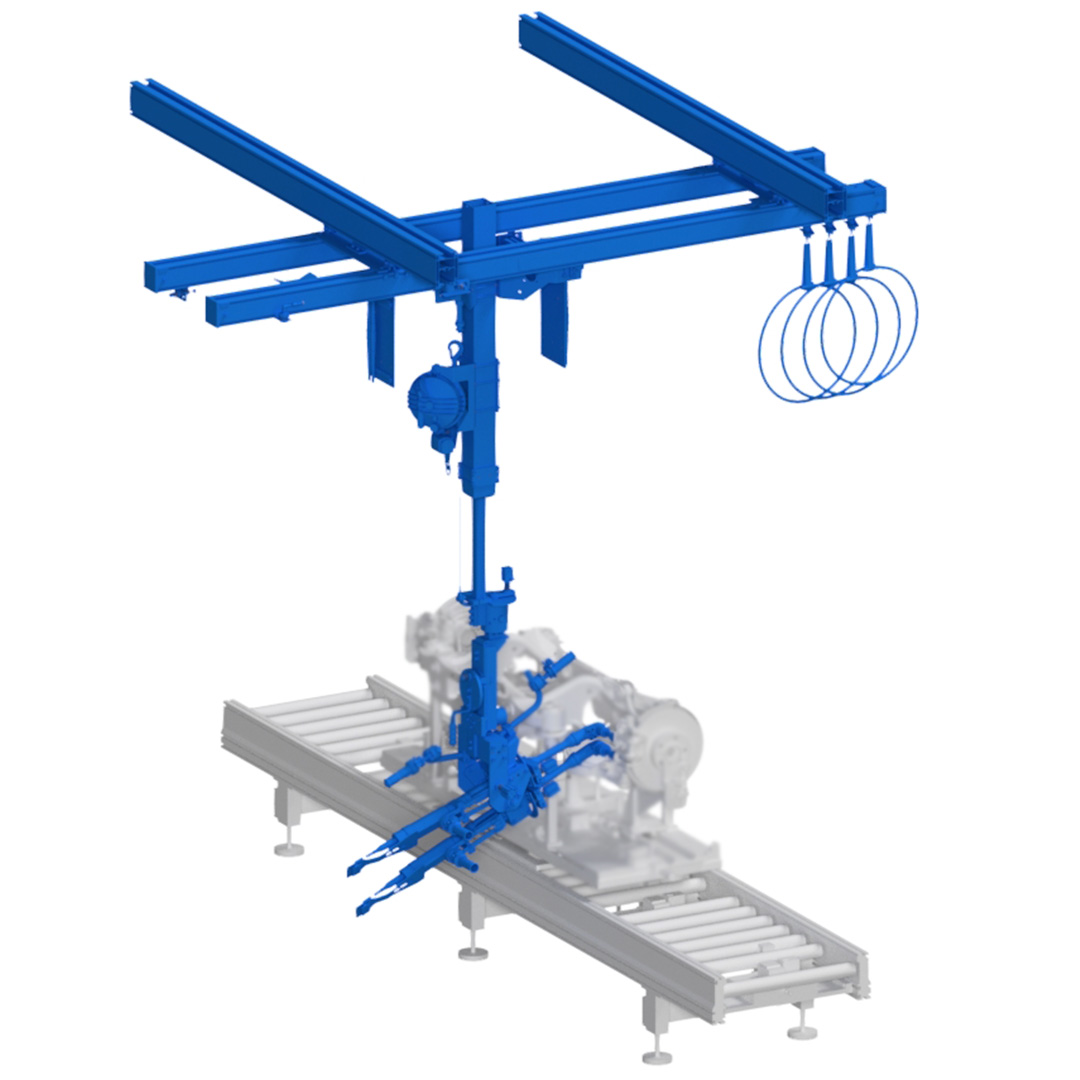

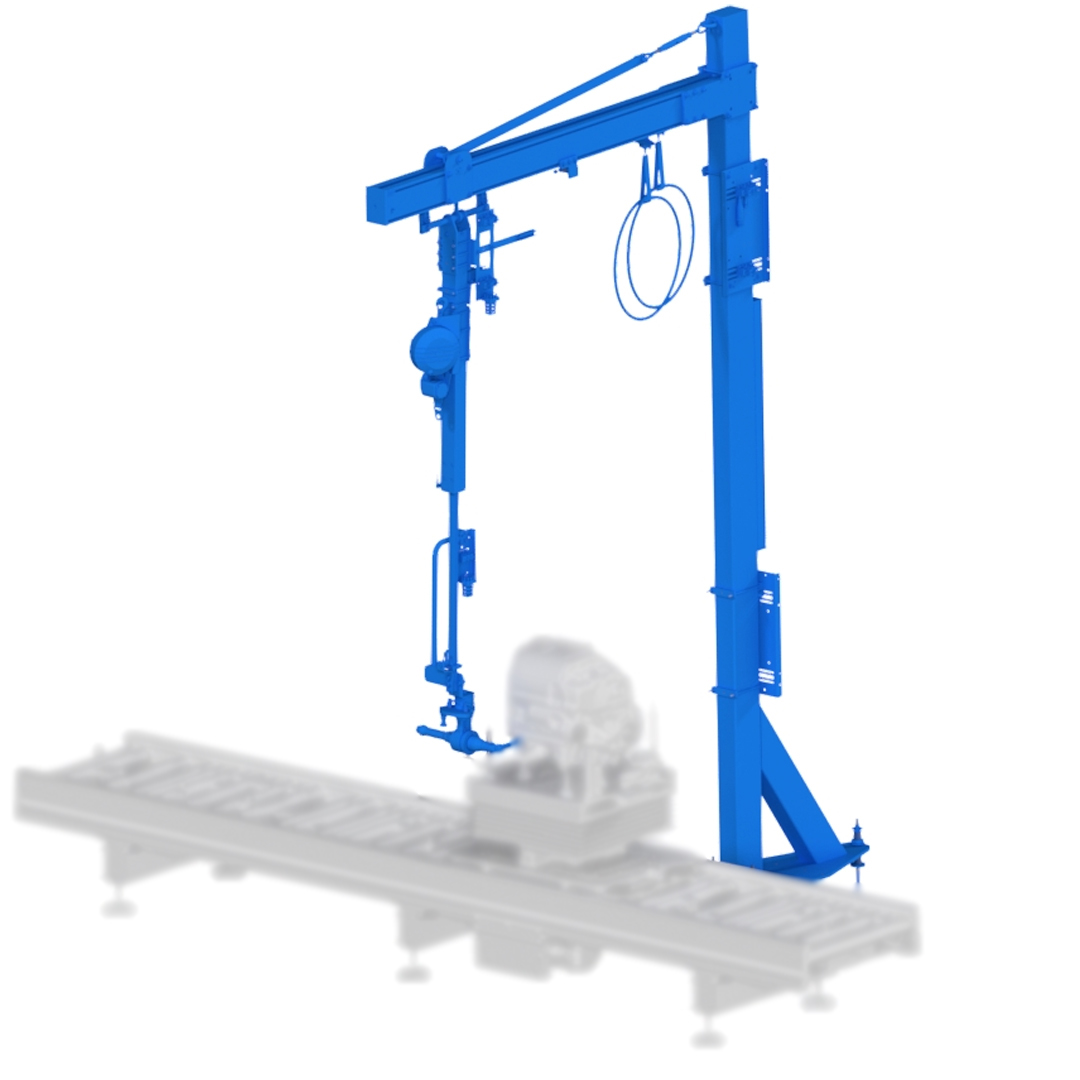

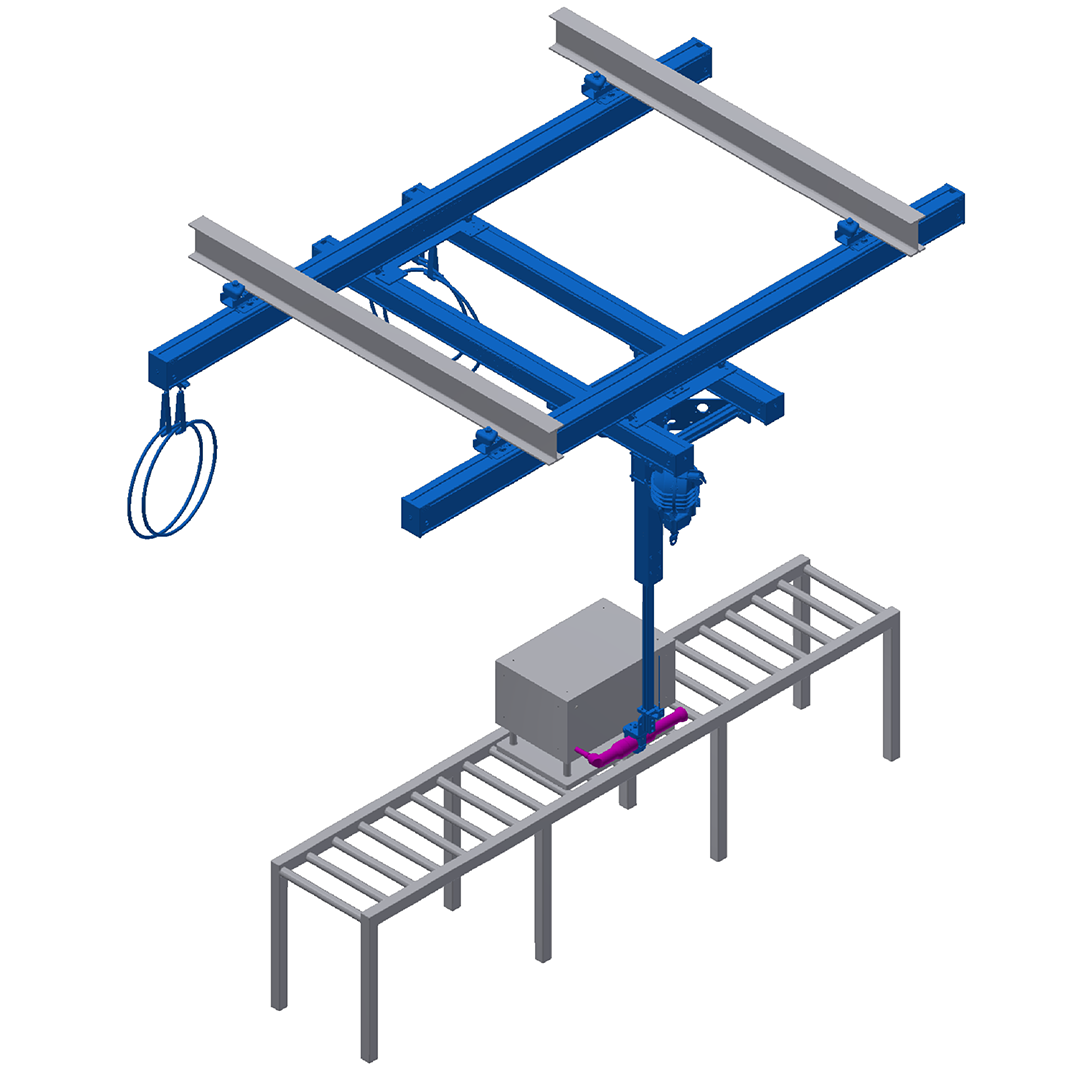

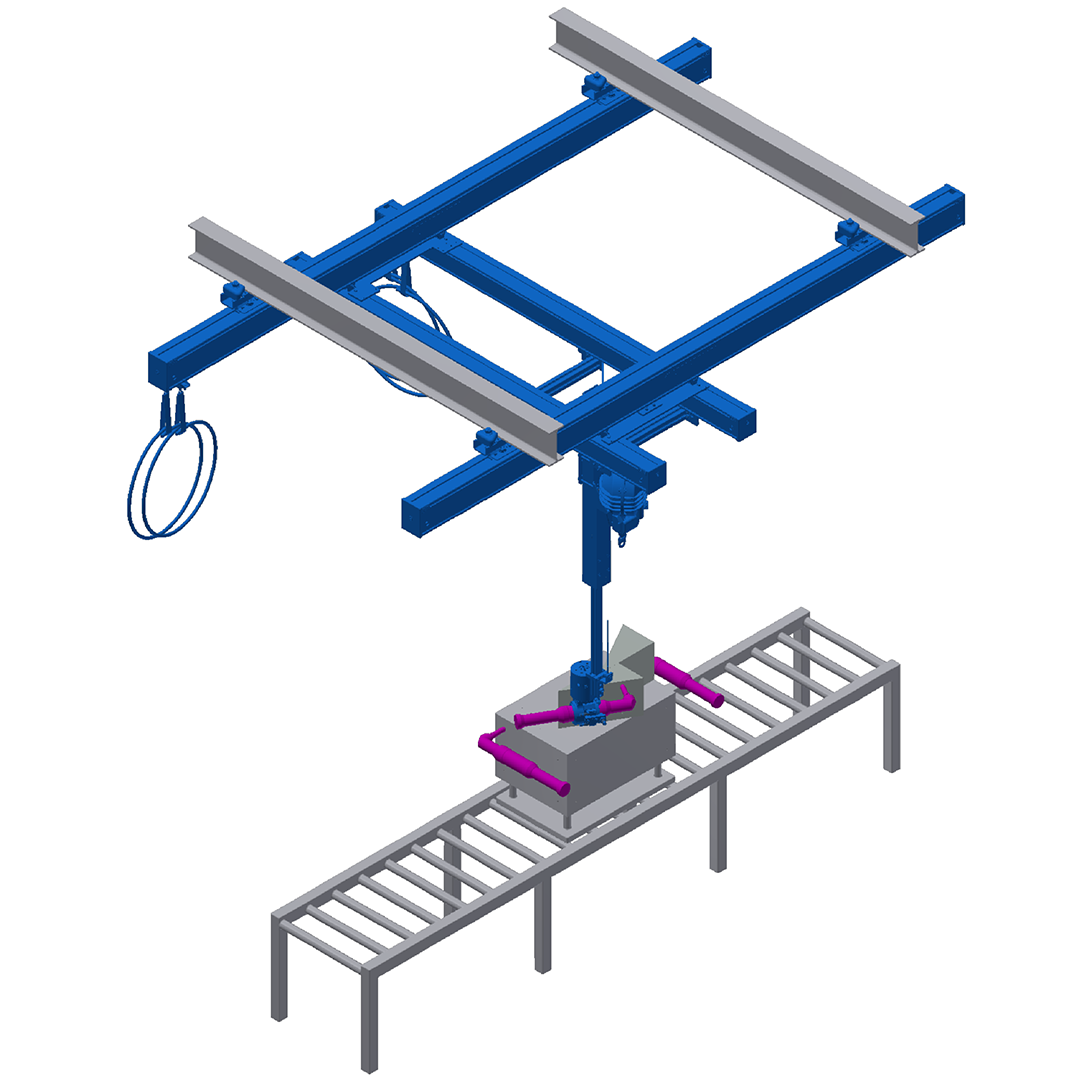

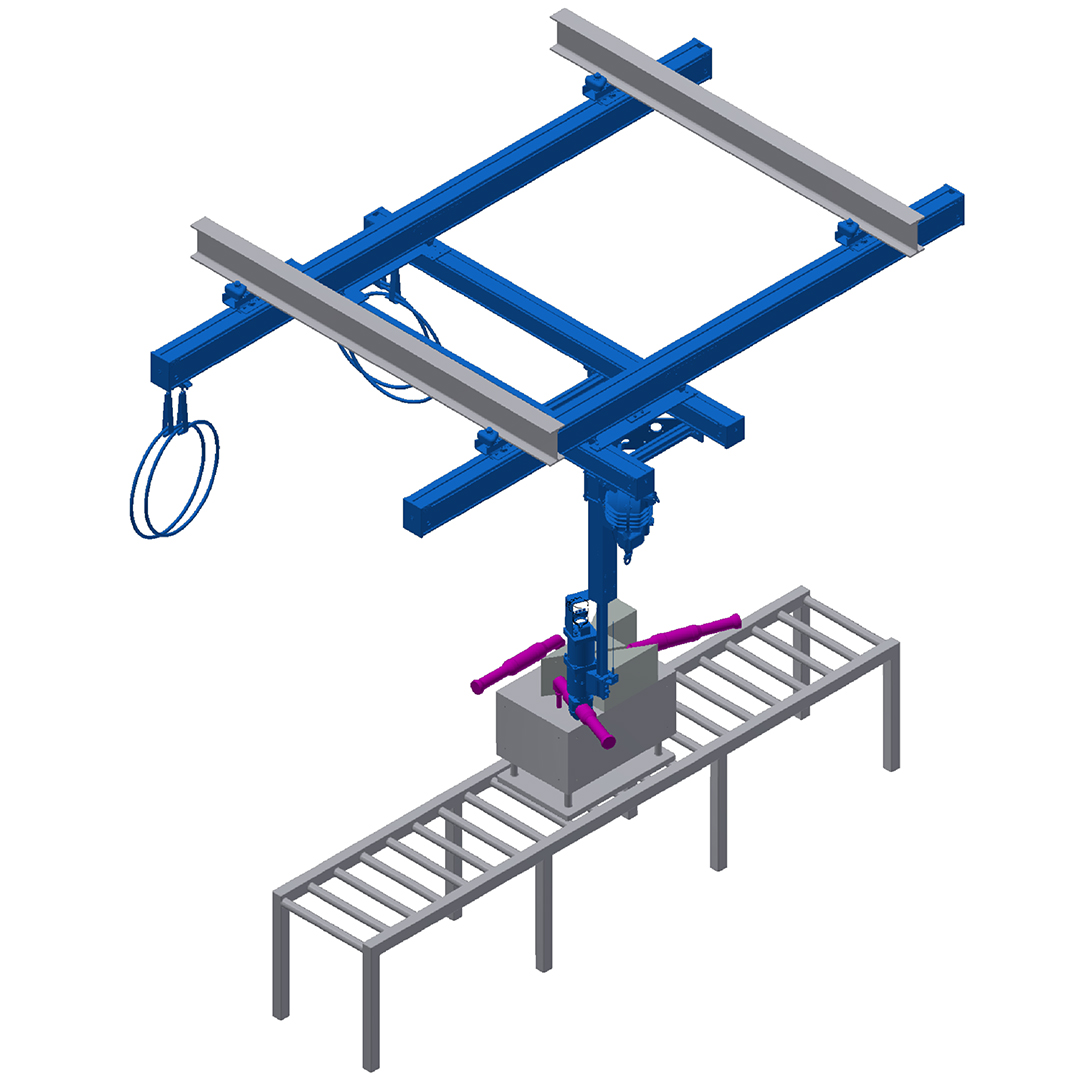

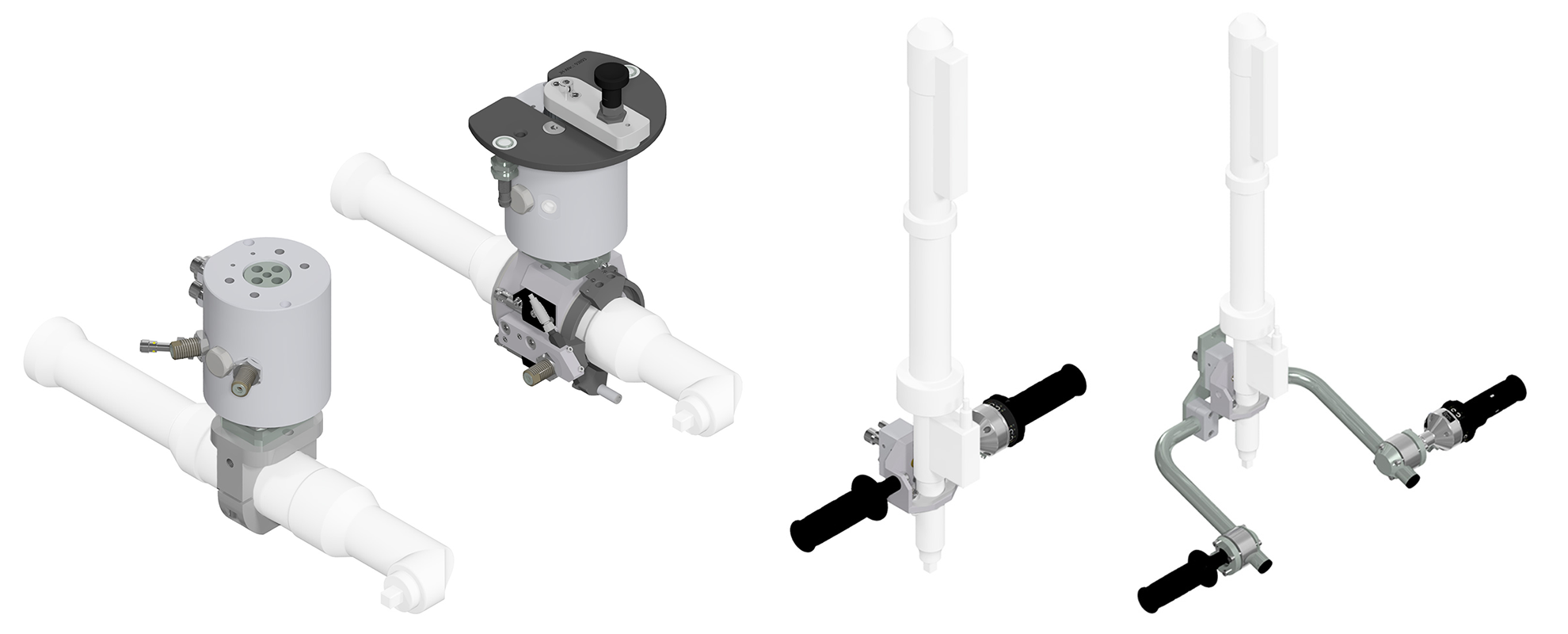

Screw direction Horizontal

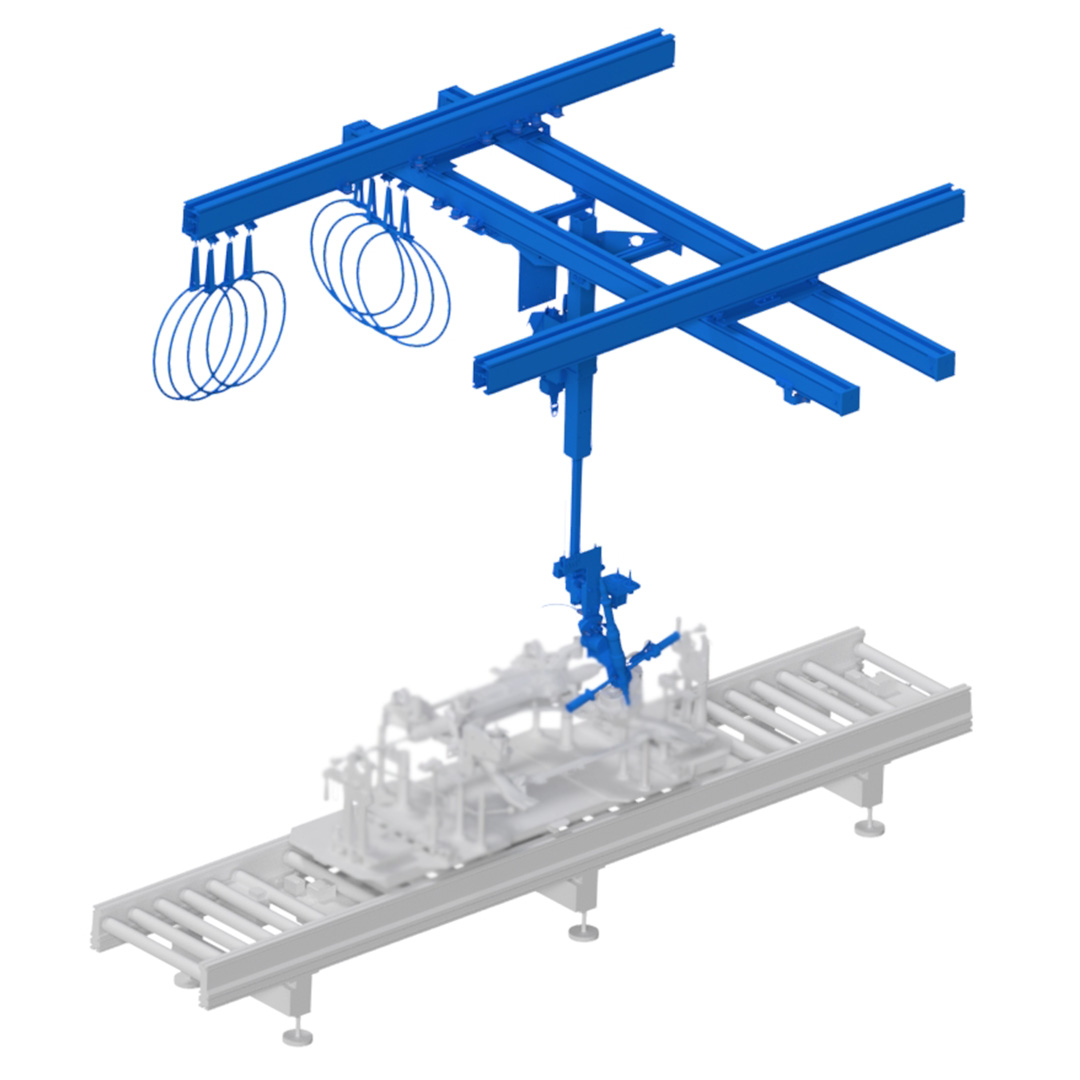

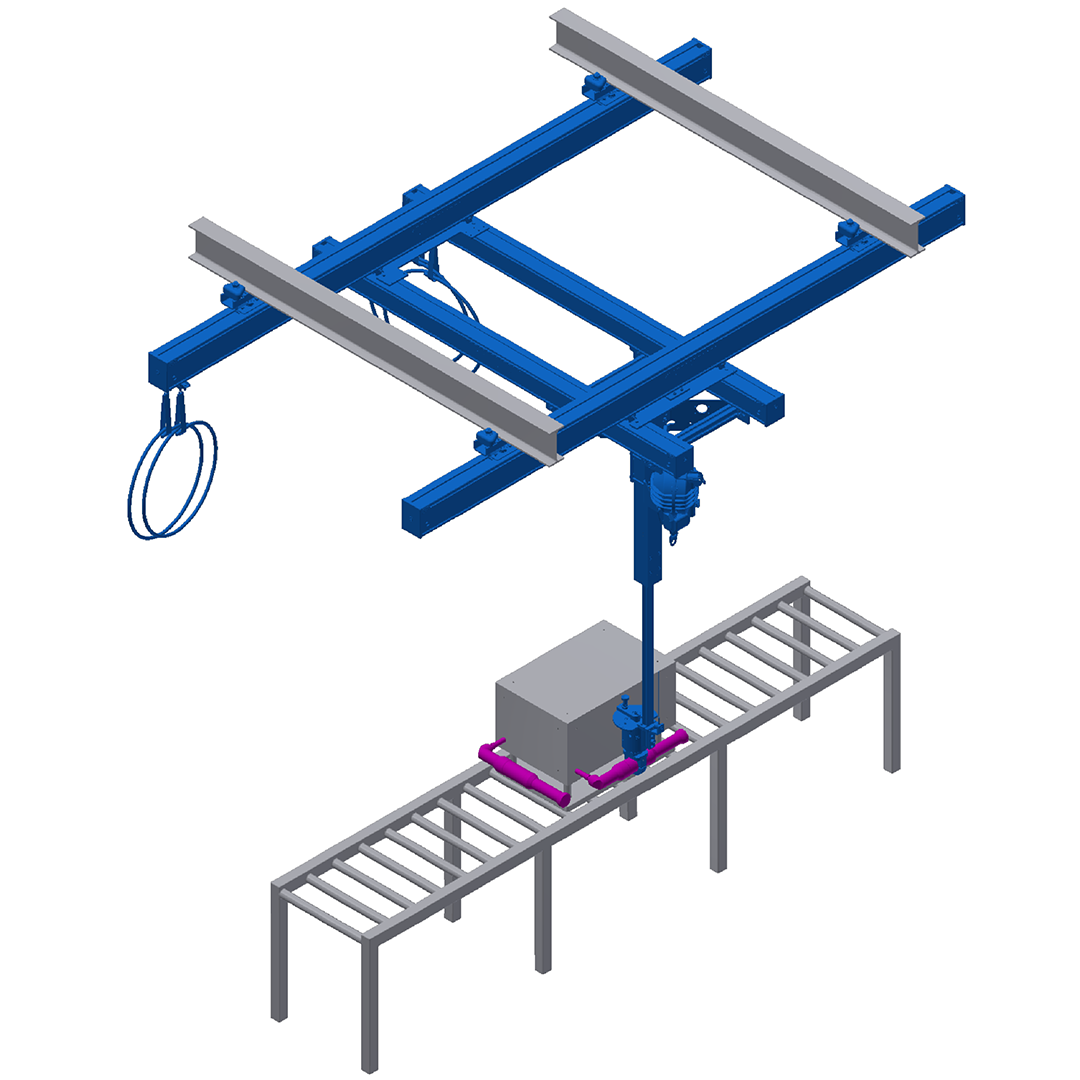

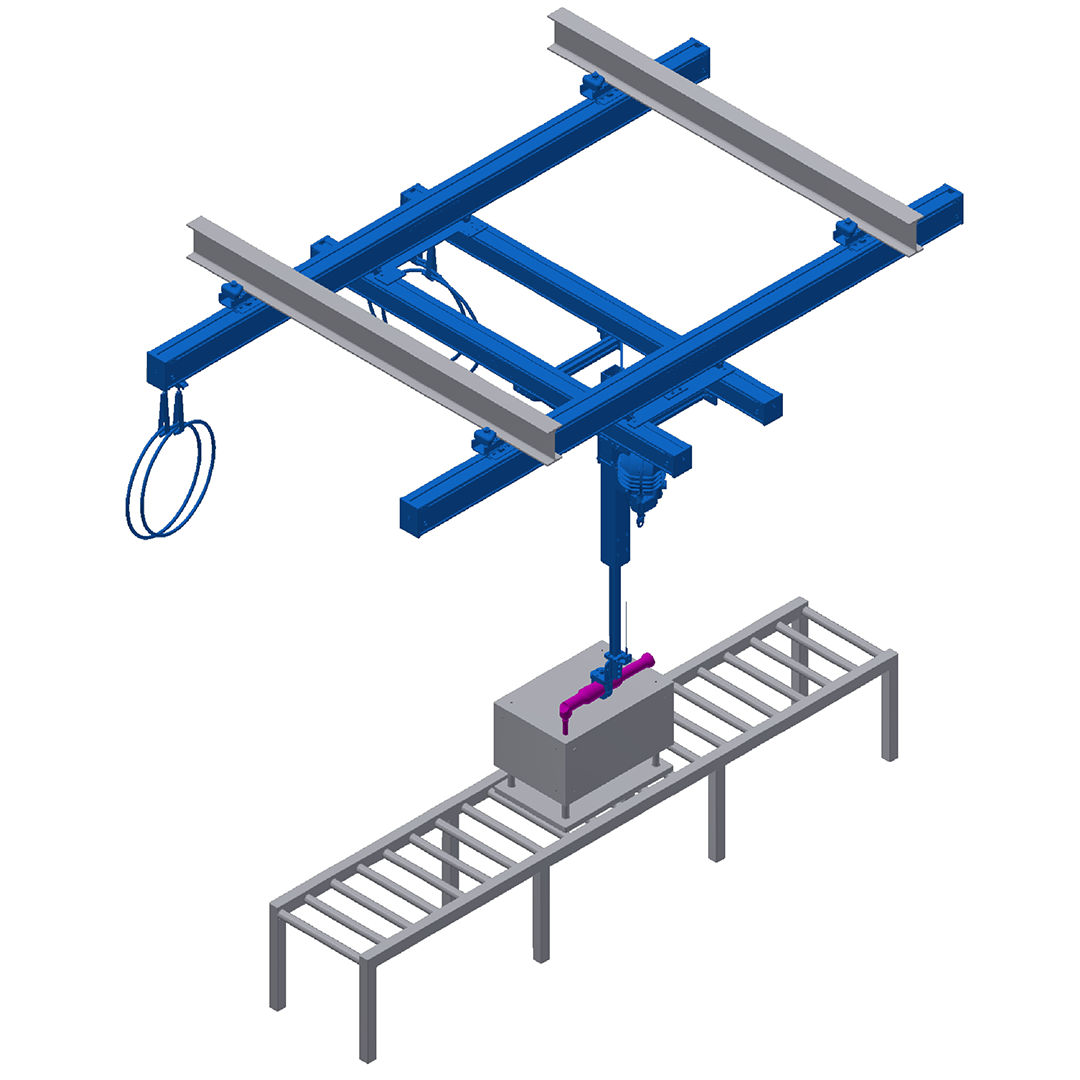

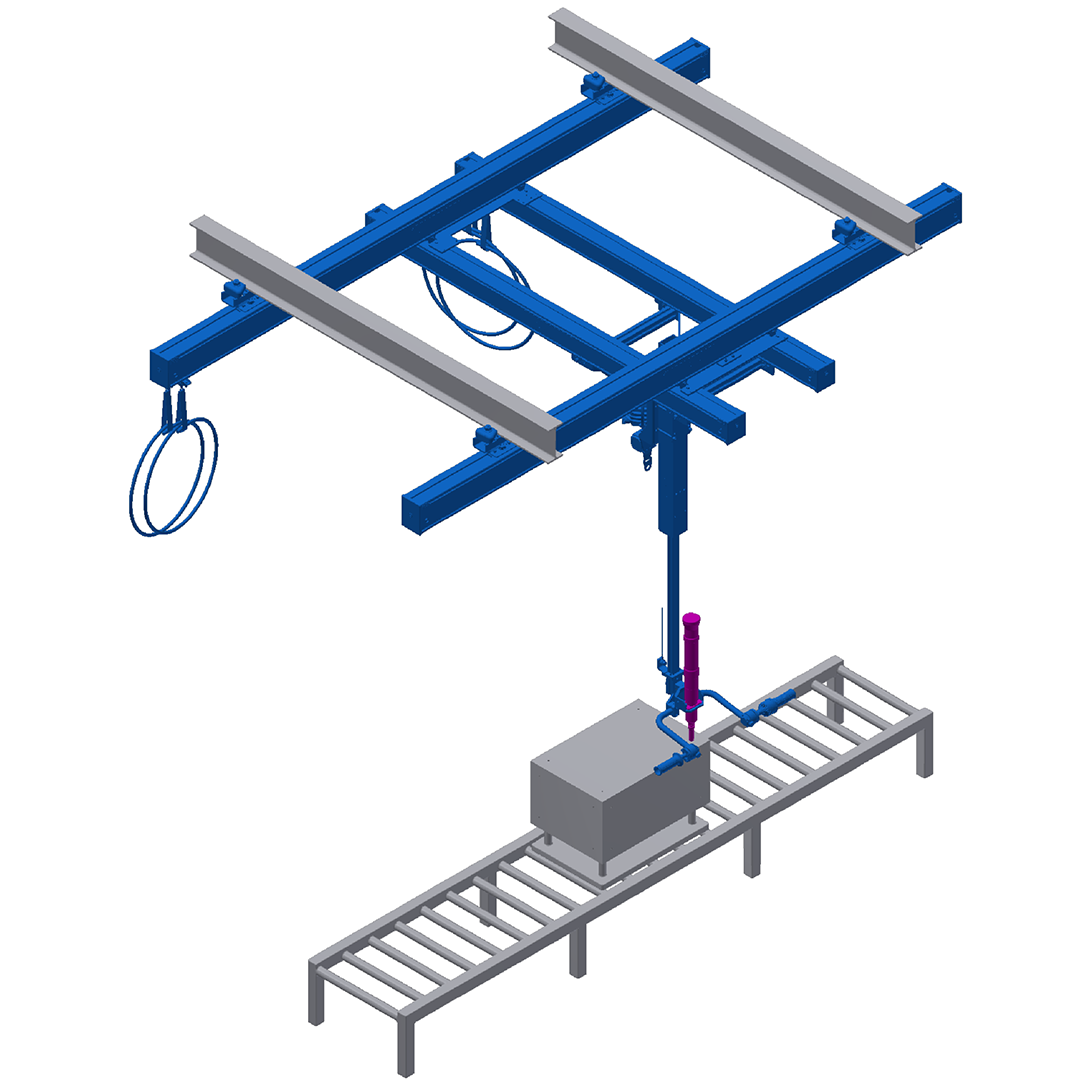

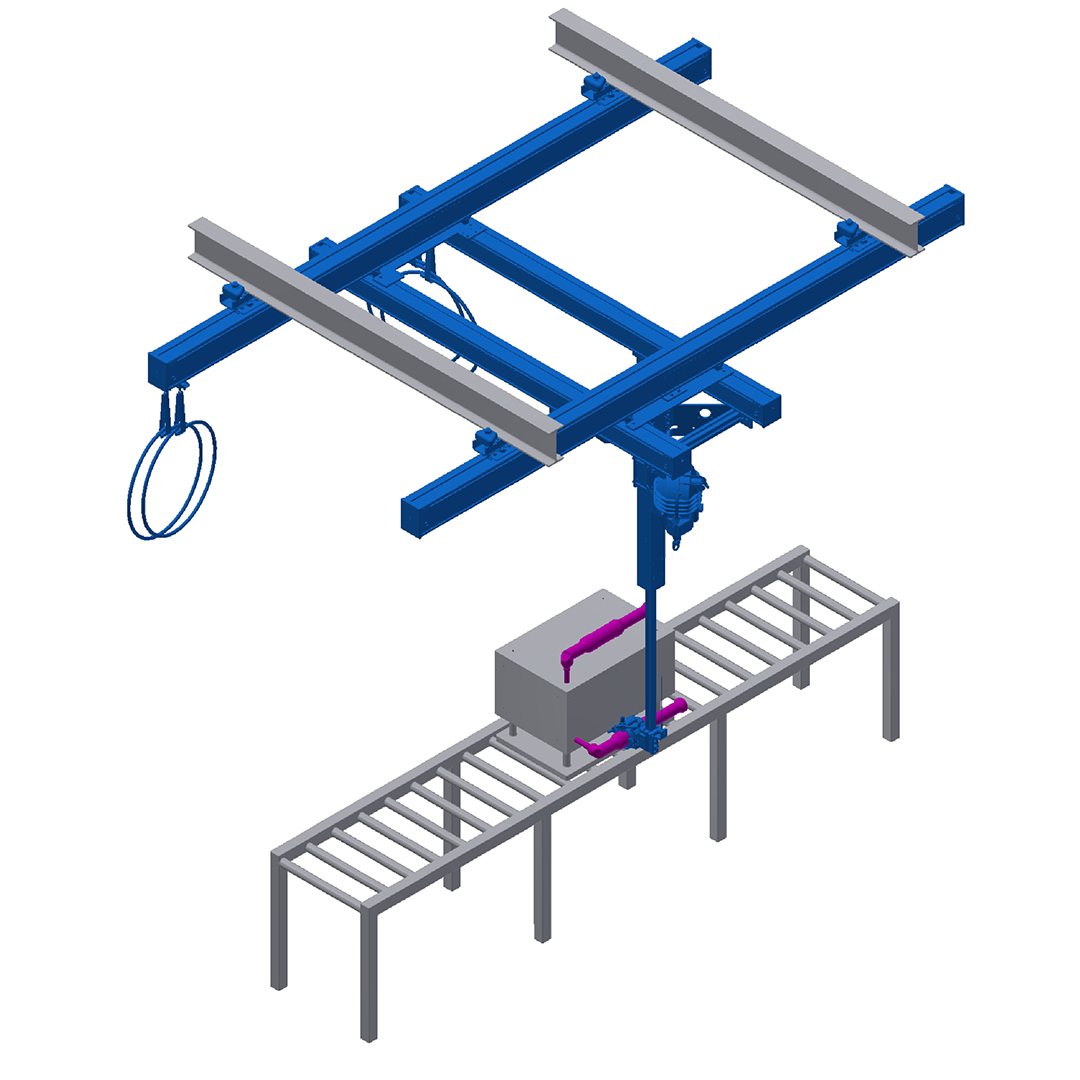

Screwing direction vertical

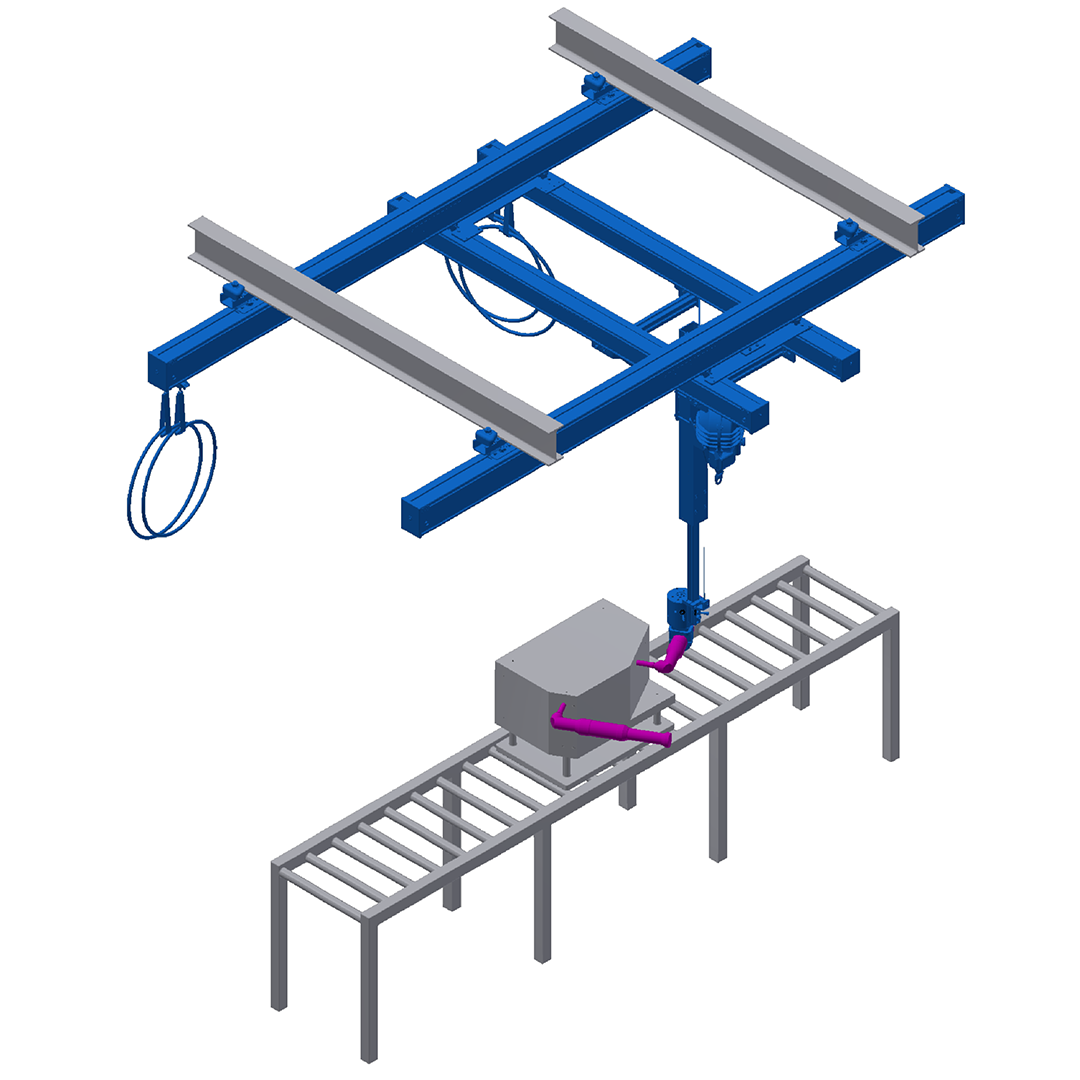

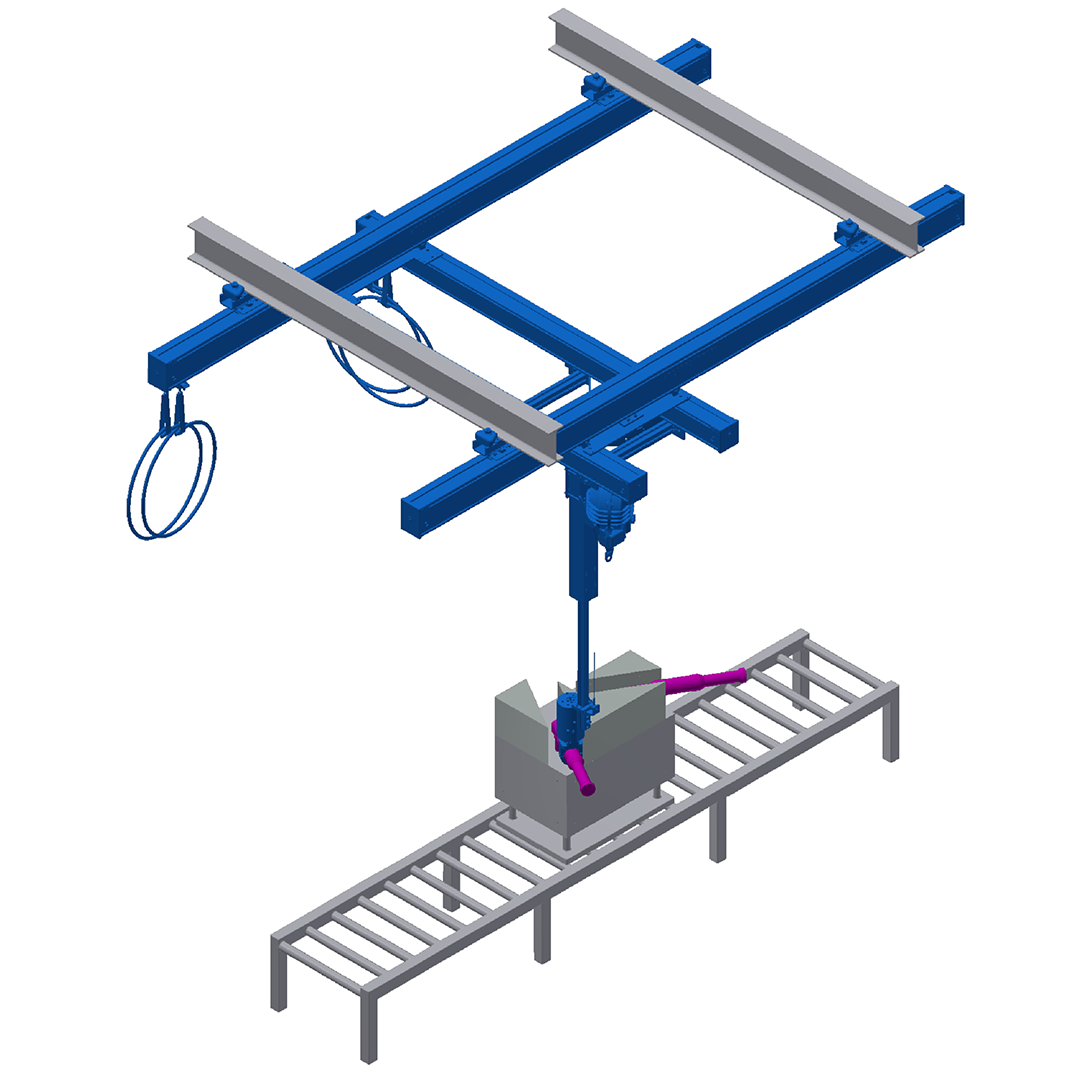

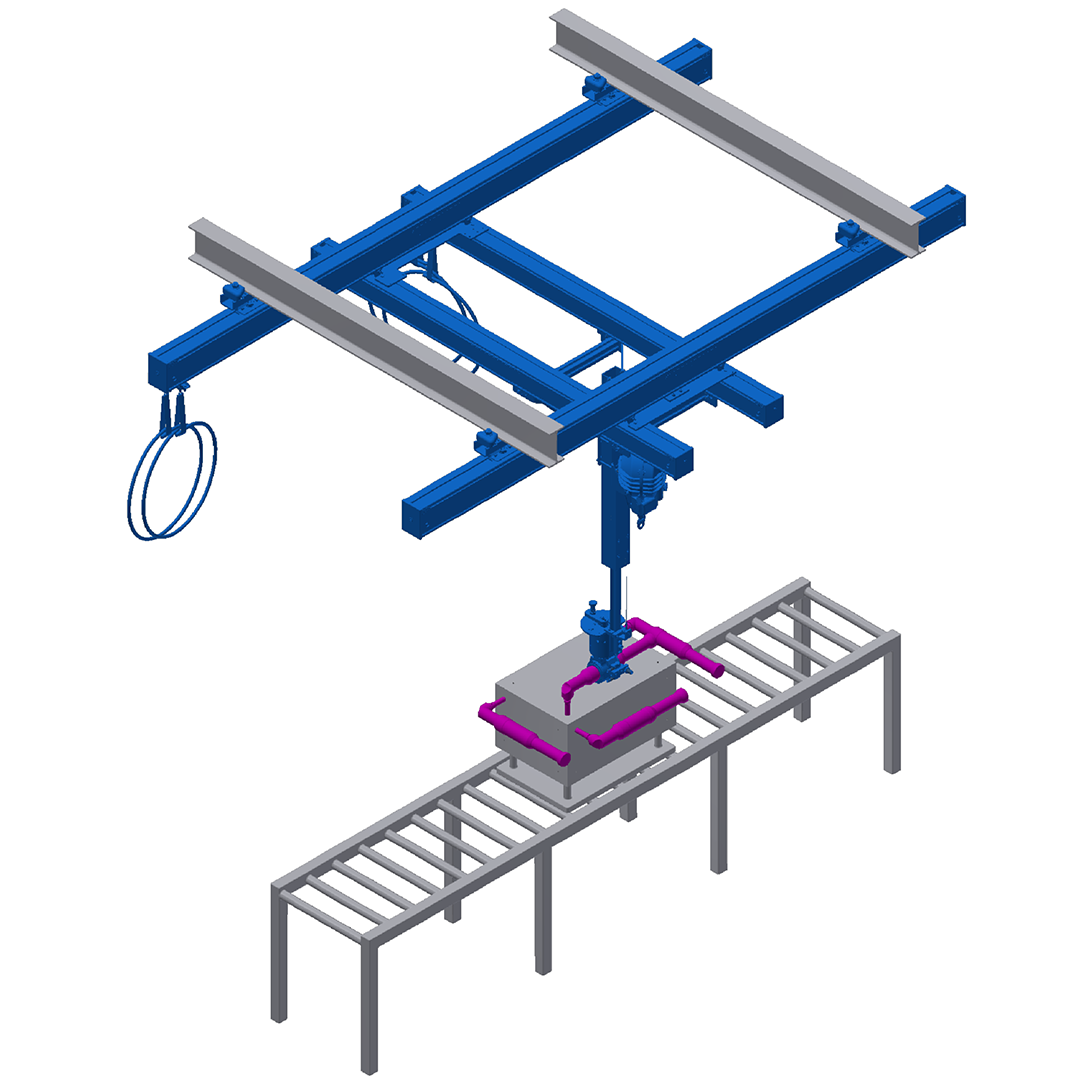

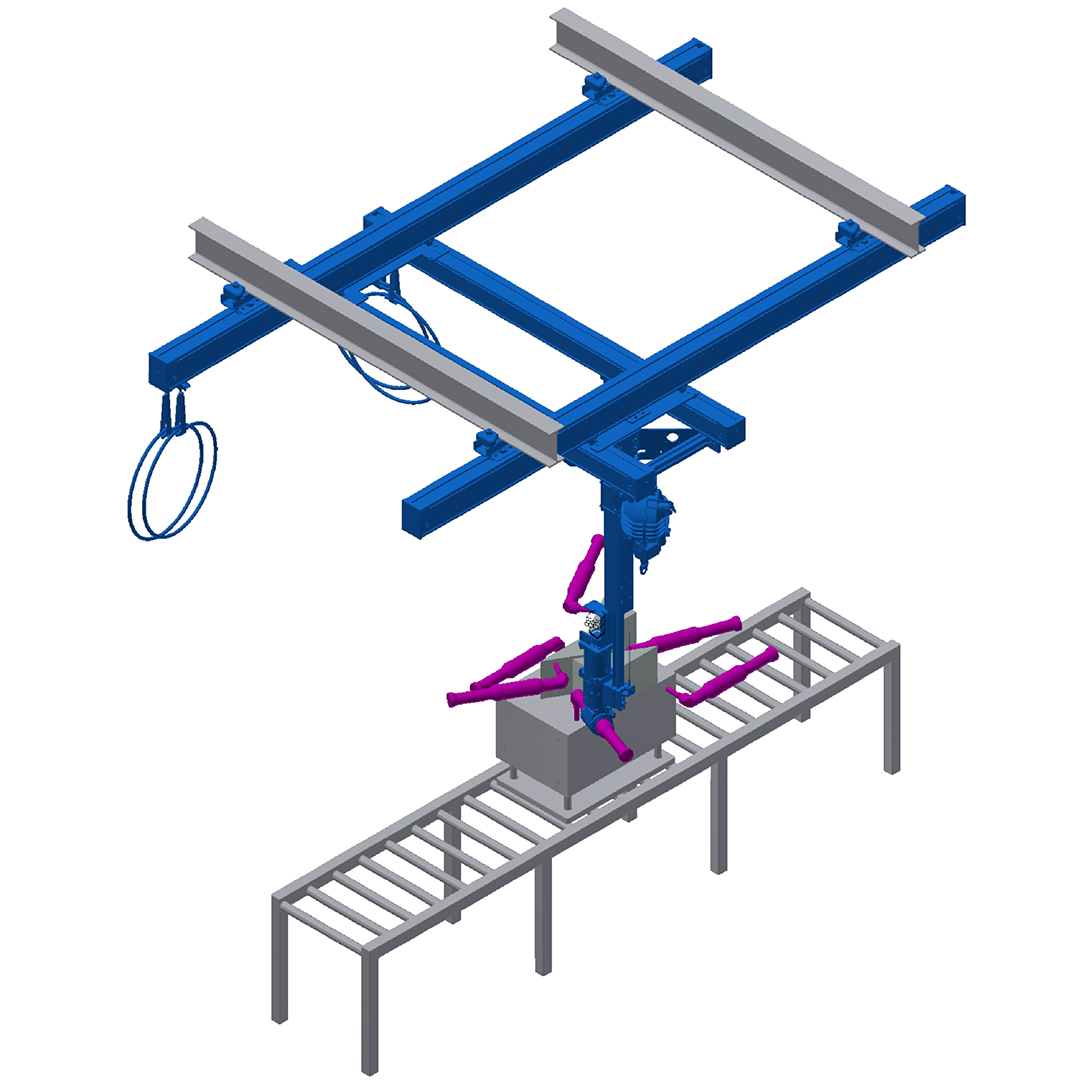

Screw direction Horizontal and Vertical

Product advantages

System design & flexibility

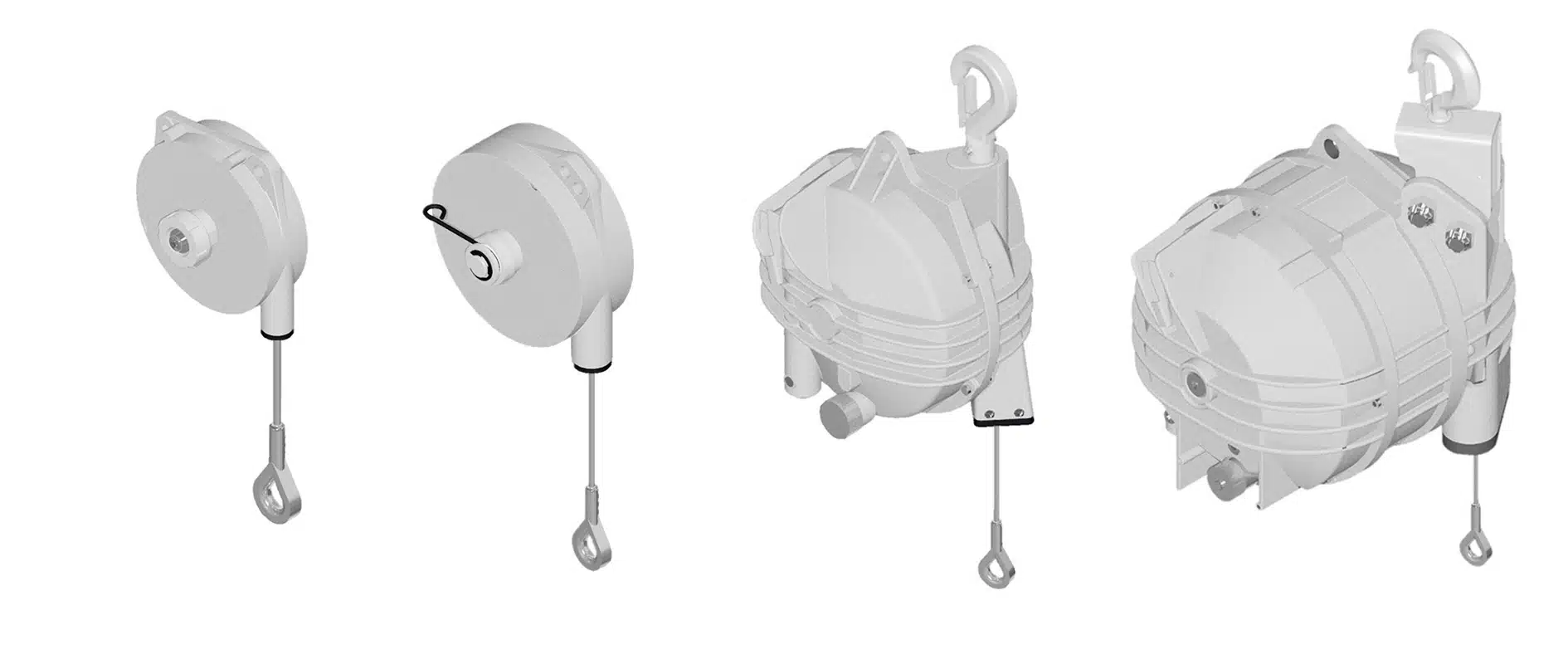

Modular system for application-specific configurations

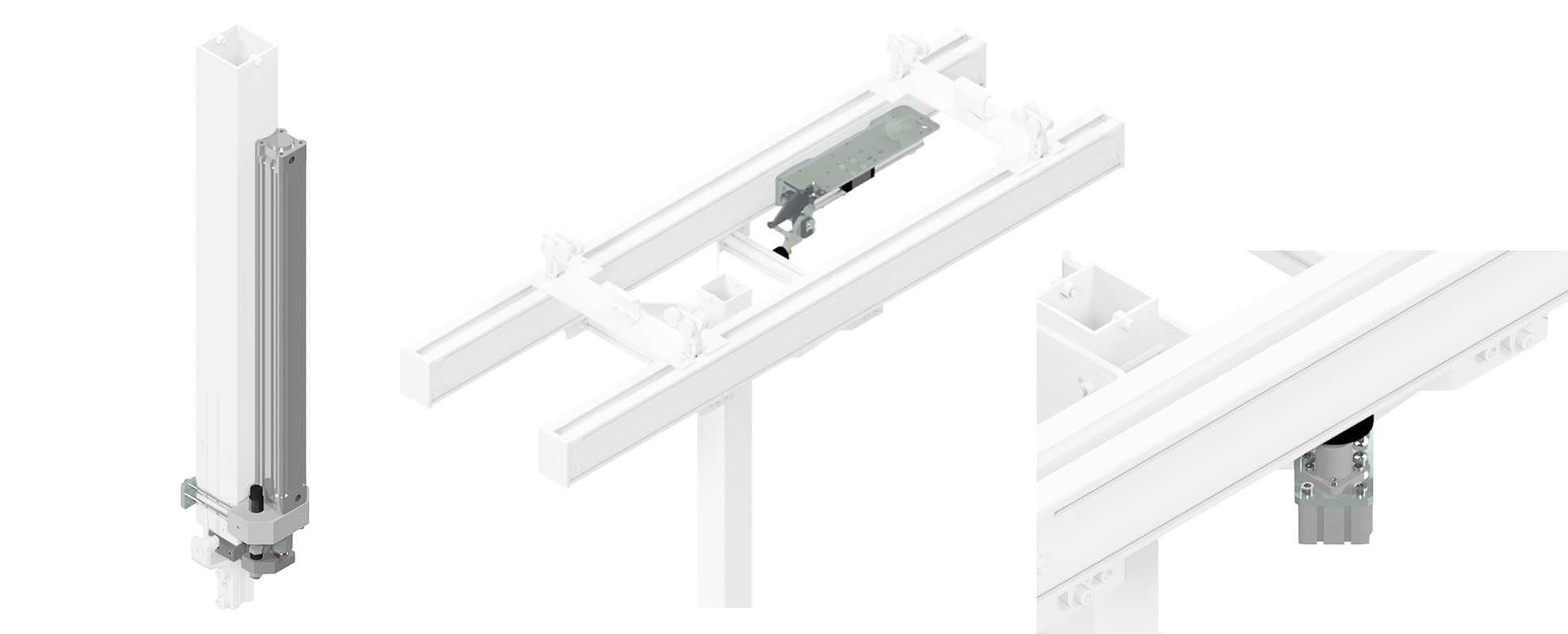

Strokes selectable in increments up to 800 mm and infinitely adjustable

Weight-optimized design for smooth handling

Flexible configurations for a wide variety of screwdriving applications

Performance & ergonomics

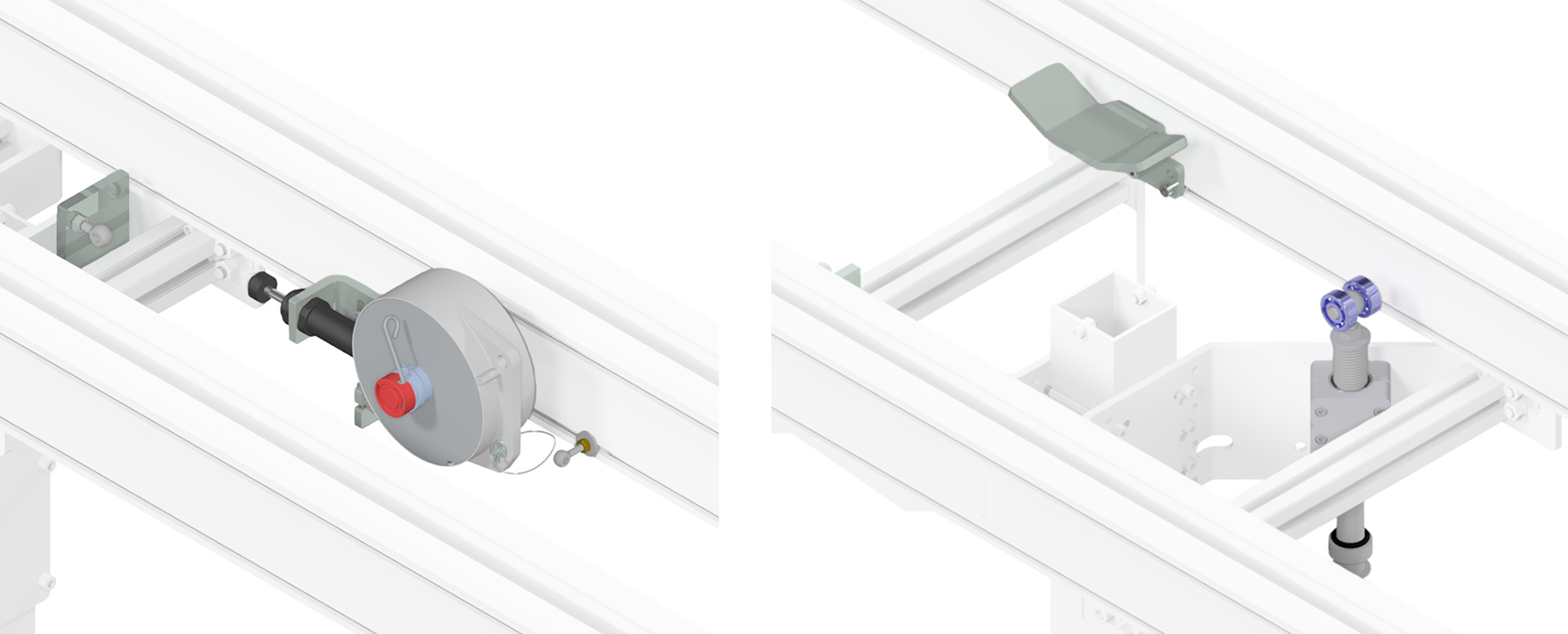

Very smooth running thanks to ball screw guide

Torque support up to 1,500 Nm

Load capacities up to 500 kg

Expandable from partially automated to fully automated handling station

Process integration & operational safety

Easy integration into existing cycle and flow assembly lines

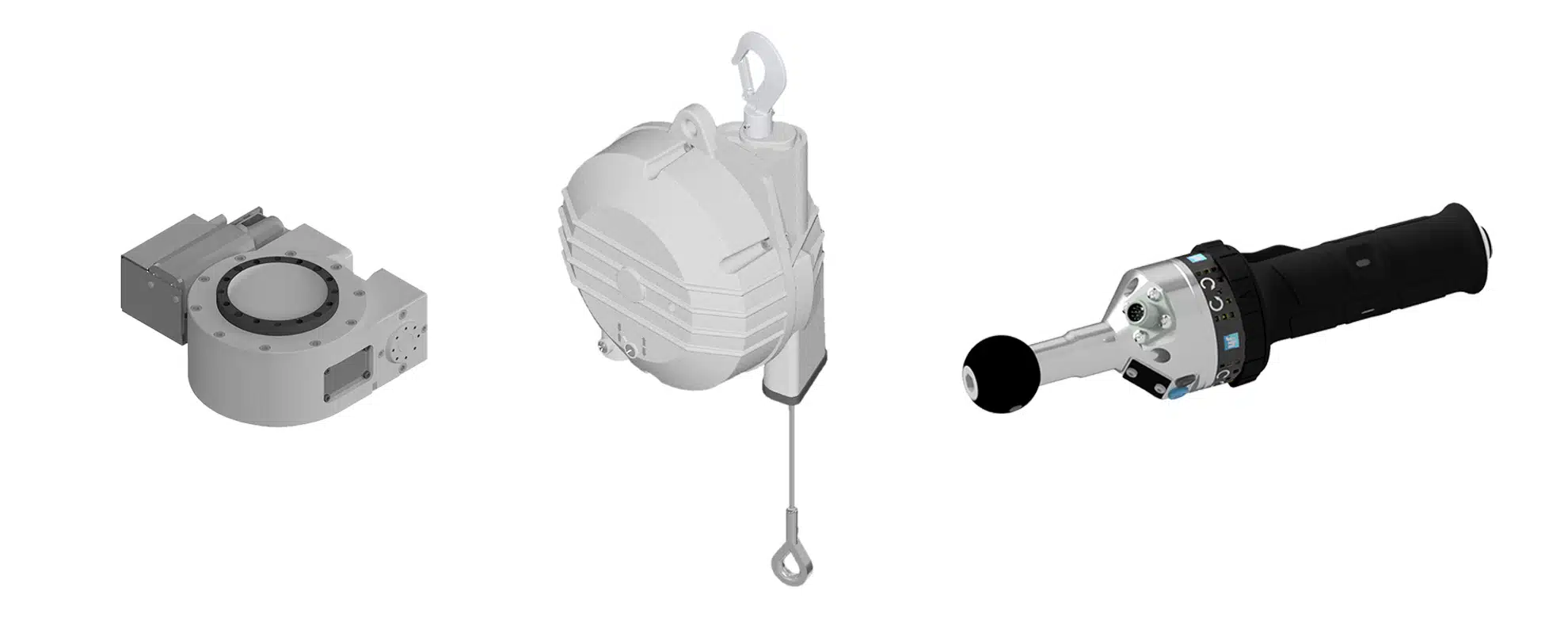

Acceptance of hand-held and built-in screwdrivers from a wide range of manufacturers

Low-maintenance, durable and designed for continuous industrial operation

High process reliability through engineering made in Sulzbach-Laufen

Series

* As the stroke increases, the maximum payload and transferable torque decrease.