Welcome to the world of component screwdriving technology. Here you will find an overview of our various products. Each individual component can be found in a wide variety of applications and is a great support in the field of screwdriving technology.

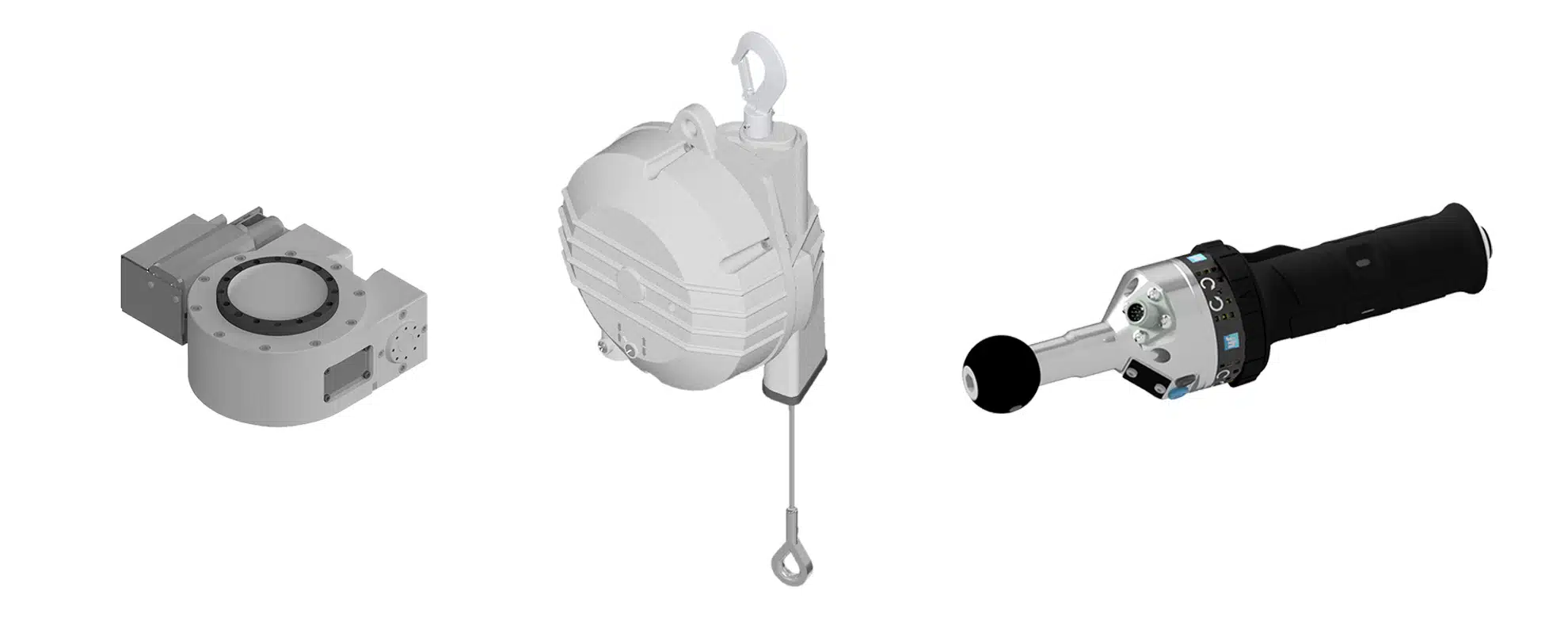

Flat Offset Drives

Our flat offset drive is a special drive in screwdriving technology, developed to reach screwing points that are not accessible with conventional angle heads or other standard offset drives. This type of offset drive is often used in tight or hard-to-reach areas where space is limited and a precise screw connection is required. Due to their compact design, flat offset drives are versatile and ideally suited for various industrial applications.

Properties

Max. output torque: 650Nm

Compact design

Galvanically Isolated Offset Drives

Our flat offset drive is a special drive in screwdriving technology, developed to reach screwing points that are not accessible with conventional angle heads or other standard offset drives. This type of offset drive is often used in tight or hard-to-reach areas where space is limited and a precise screw connection is required. Due to their compact design, flat offset drives are versatile and ideally suited for various industrial applications.

Properties

Max. torque range: 150Nm

Fastening of standard bits

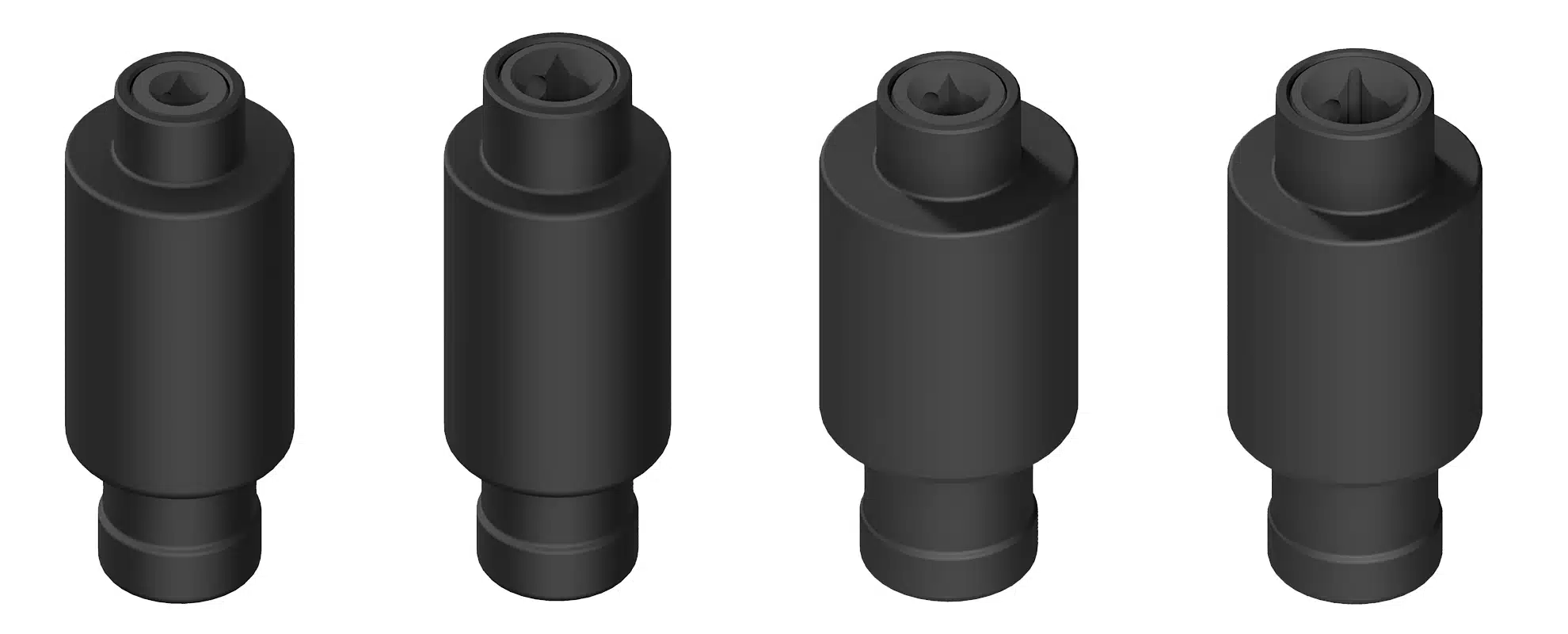

Galvanically Isolated Quick-Change Chucks

Our specially developed, galvanically isolated quick-change chucks can be attached to hand-held screwdrivers and built-in spindles and enable the use of insulated sockets and bits. The galvanic isolation and the insulated jacket surface effectively reduce the risk of contact with live components, prevent dangerous short circuits caused by high electrical currents and protect battery modules from unintentional short circuits.

Properties

Max. torque range: 150Nm

Square drive for torque input on the drive side

Internal hexagon socket used on the output side

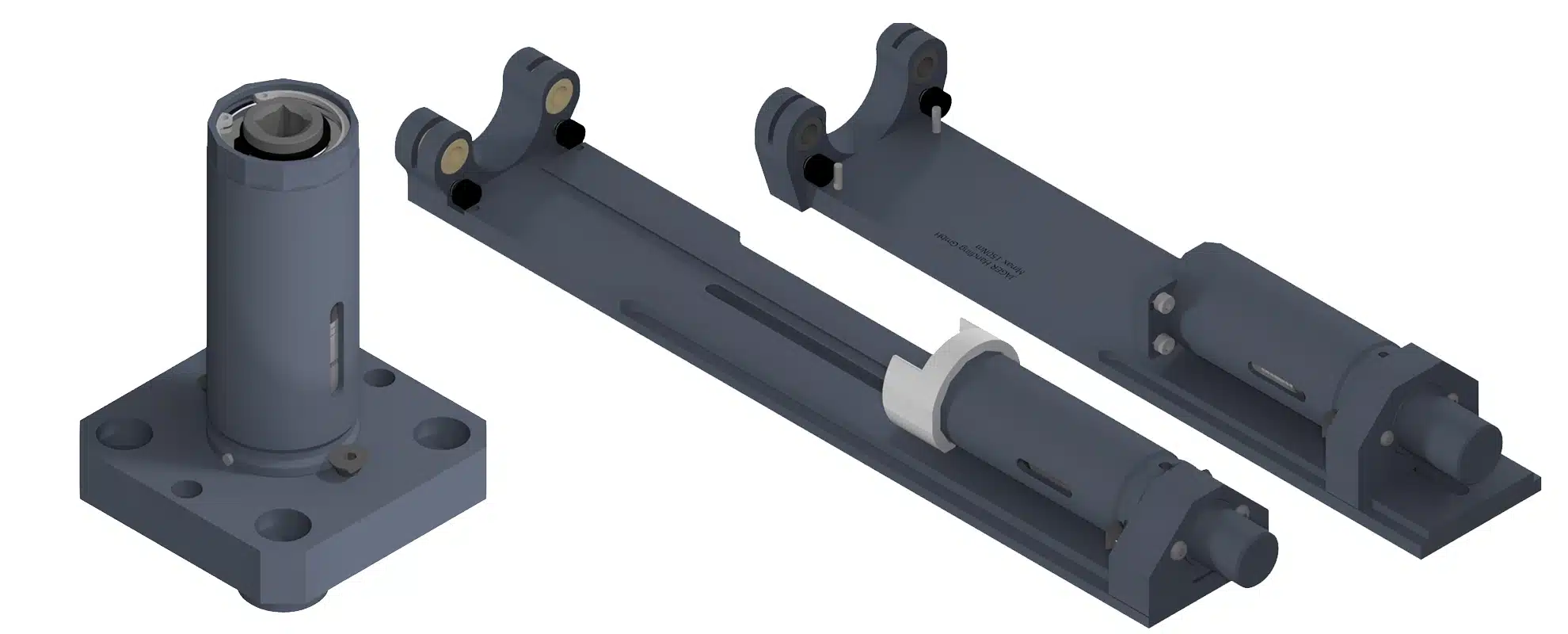

Reference measuring adapter

Reference measurement is an essential process in industrial screwdriving technology, which is used in both electrically controlled spindles (EC spindles) and hand-held screwdrivers. It is used for calibration and to ensure the accuracy and precision of the screwing processes. Regular reference measurements ensure that each screw connection exactly meets the specified specifications, which is of great importance, especially in safety-critical industries such as the automotive industry.

Properties

Max. drive torque: 400Nm

Usable multi-spindle applications

Steplessly adjustable screw case adapter

Angle Heads

An angle head transmits the torque at an angle, which is particularly useful for reaching hard-to-access screwing points. At JÄGER Handling, we are particularly proud of our own range of angle heads. Through our continuous pursuit of further development and the integration of new innovations, we have developed a variety of angle head designs over the years. This enables us to respond to every individual customer requirement and offer tailor-made solutions.

Properties

Max. output torque: 490Nm

Connection to hand-held screwdrivers and screw spindles from various manufacturers