Our carbo-arm consists of two or three interconnected carbon tubes, which can be divided into three product sizes. Starting with the carbo-arm 055, then the 220, up to the 400. The number in the product name stands for the possible absorption of Nm. In addition, the length of the stroke can be configured in three stages (s/m/l). The great advantages of the hardened carbon fibers are, on the one hand, a very stable construction and a very good absorption of the resulting torque of the connected screwdriver.

Configurations

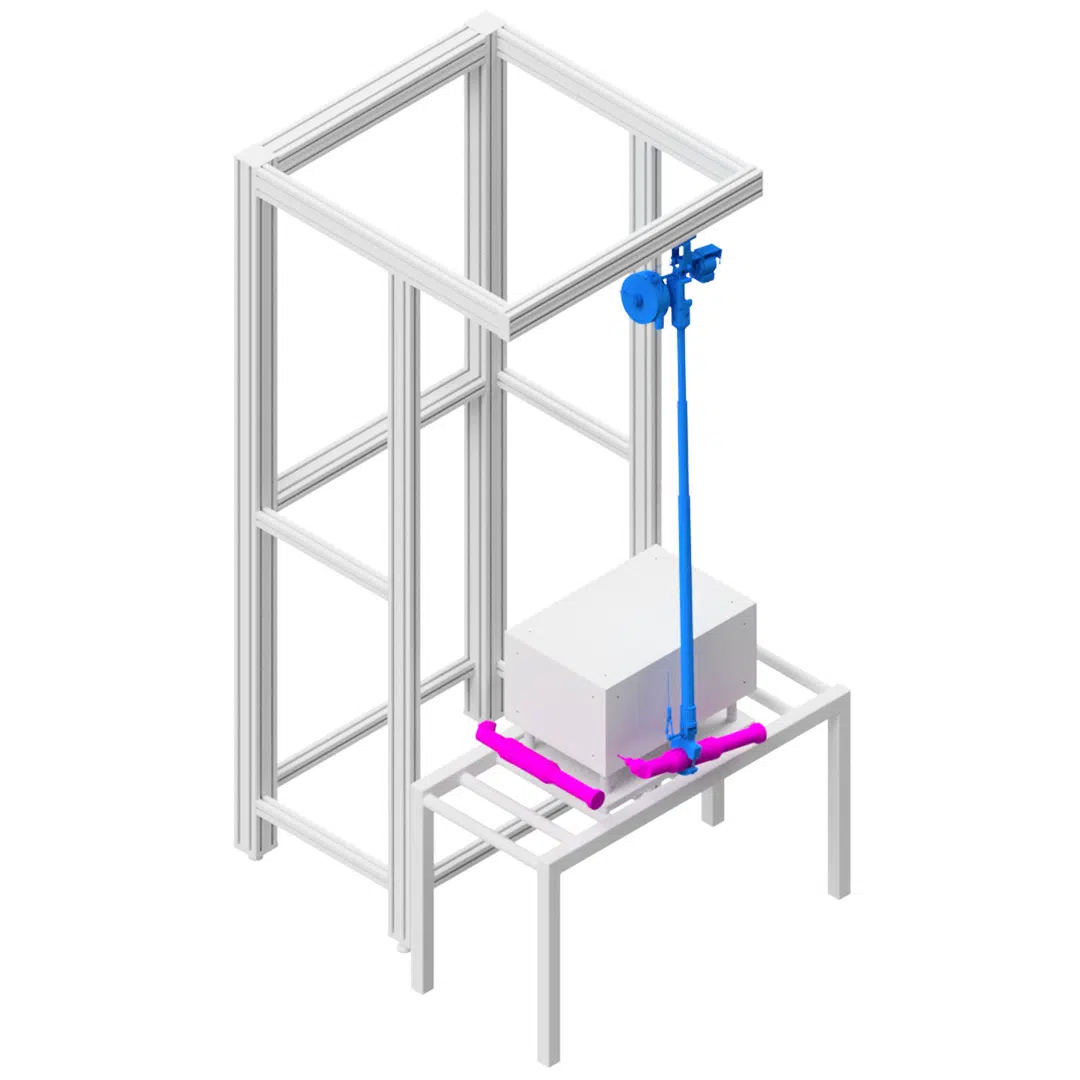

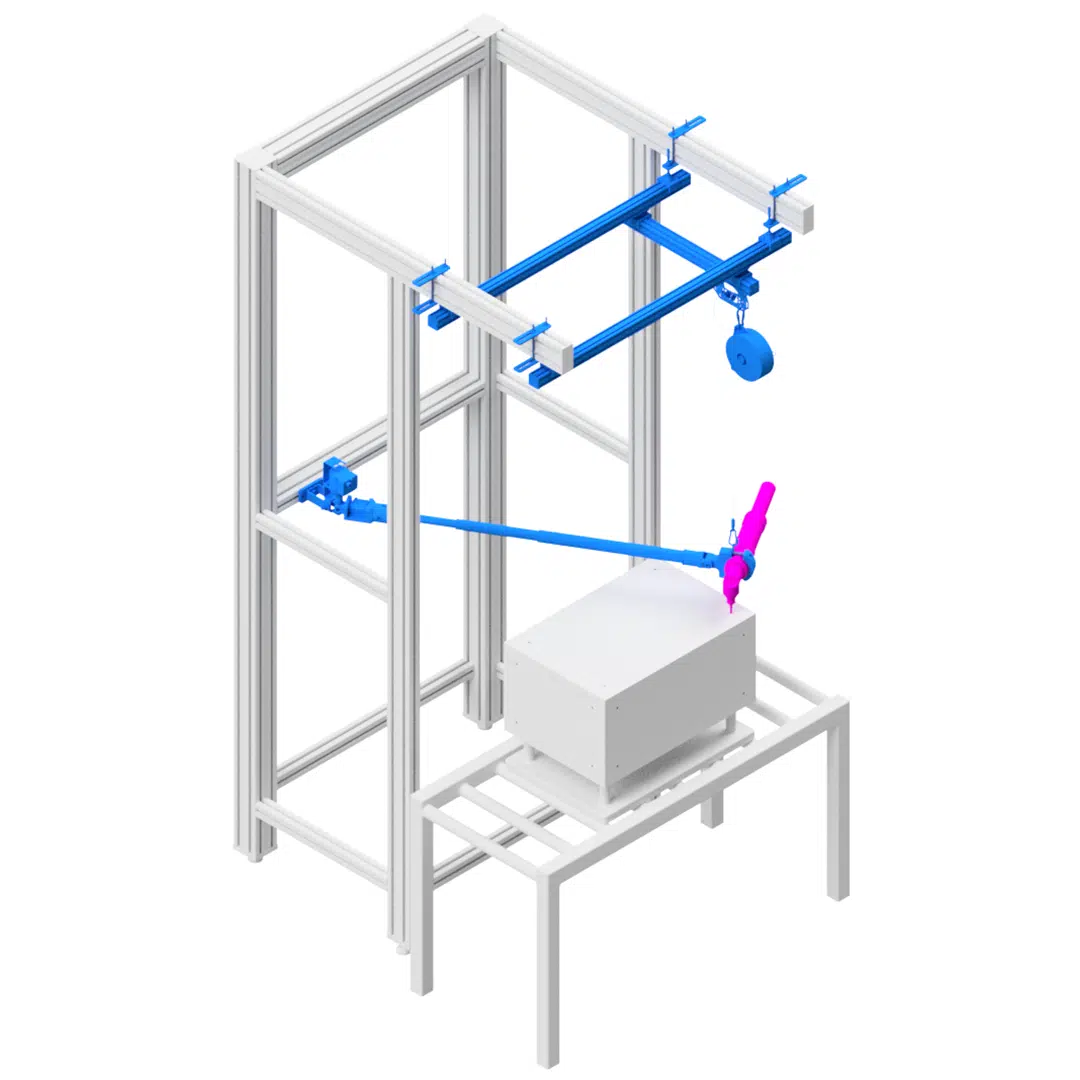

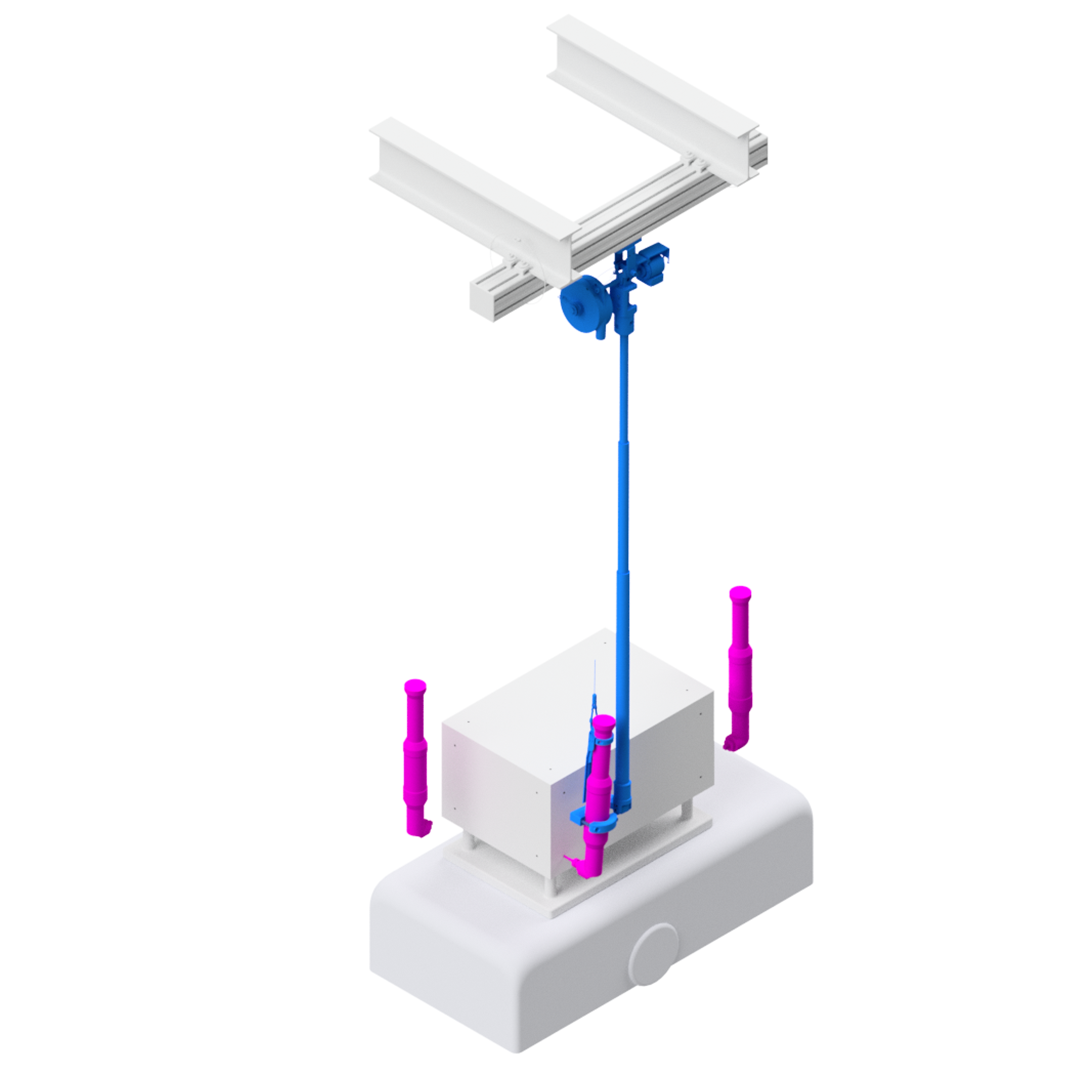

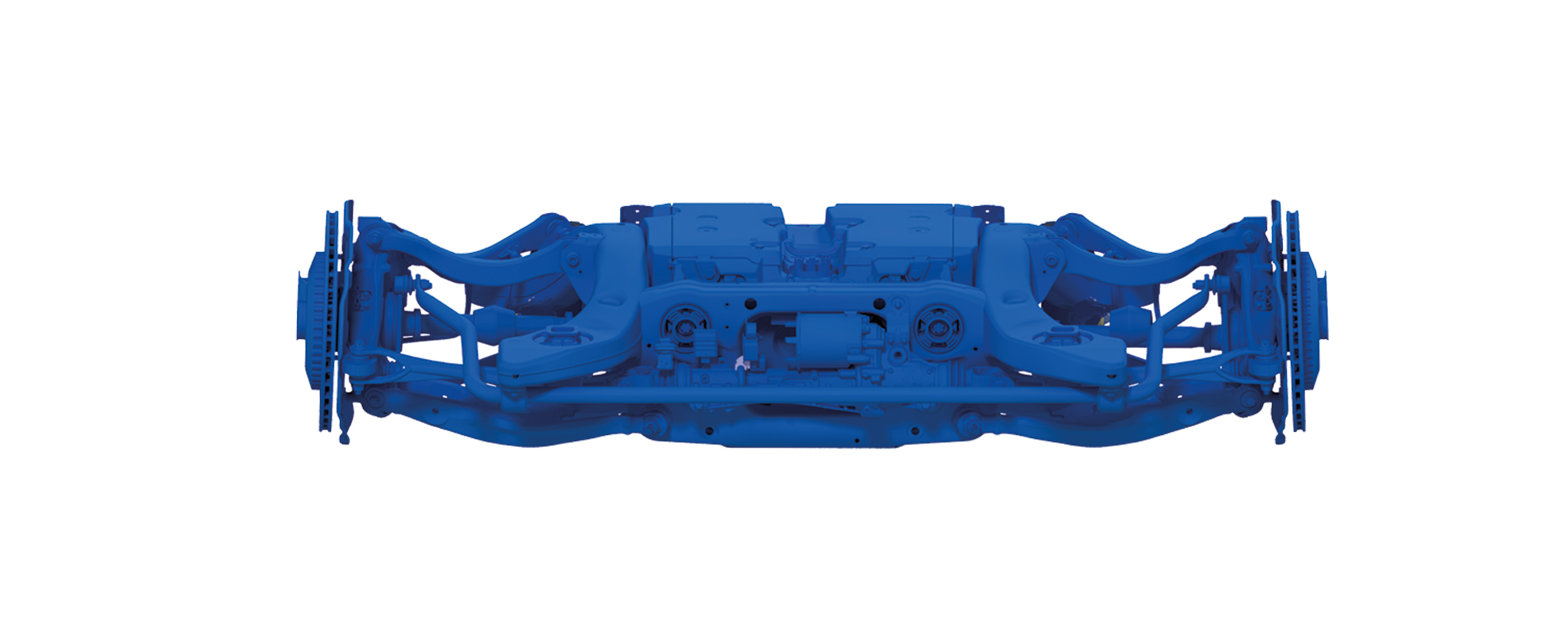

Screwing direction horizontal

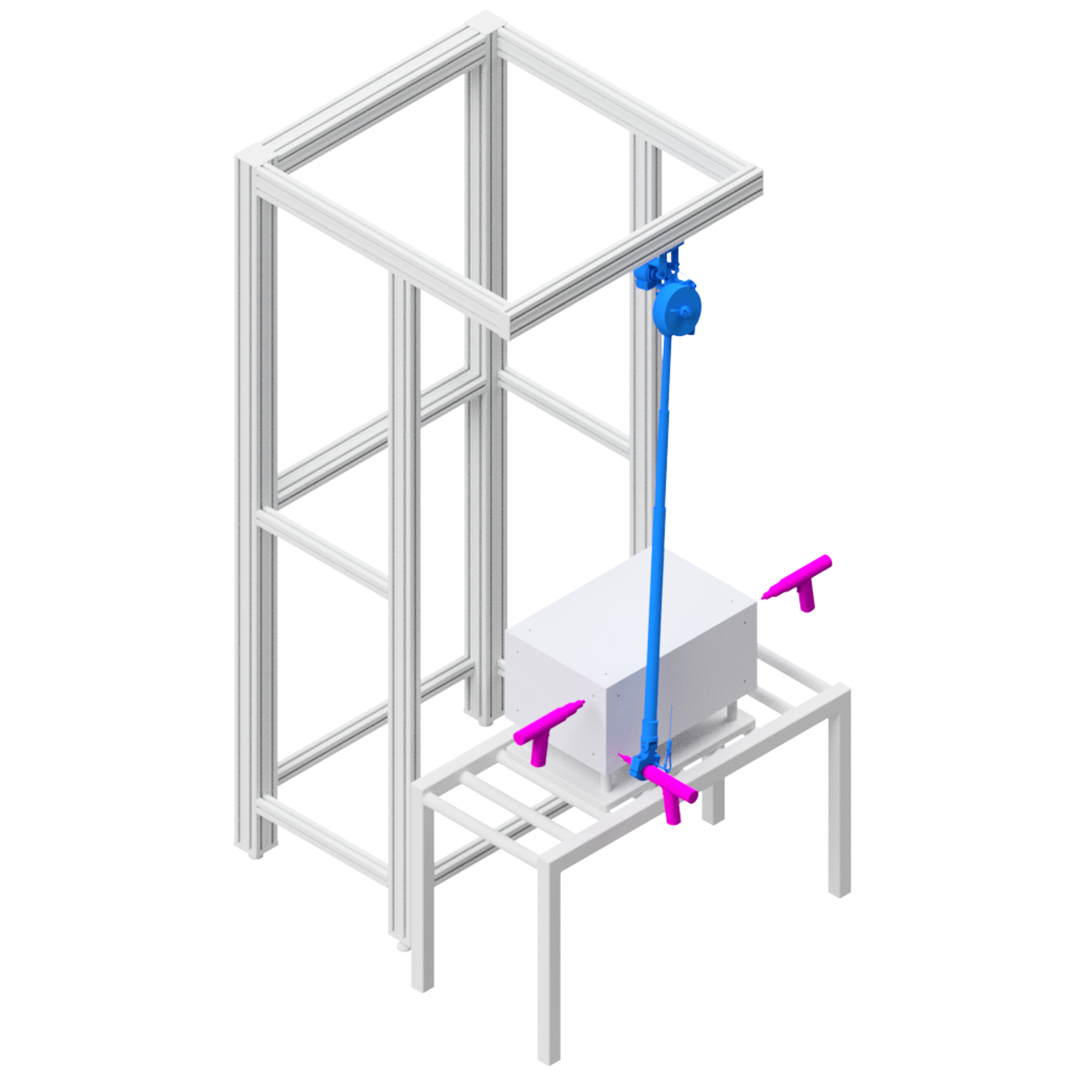

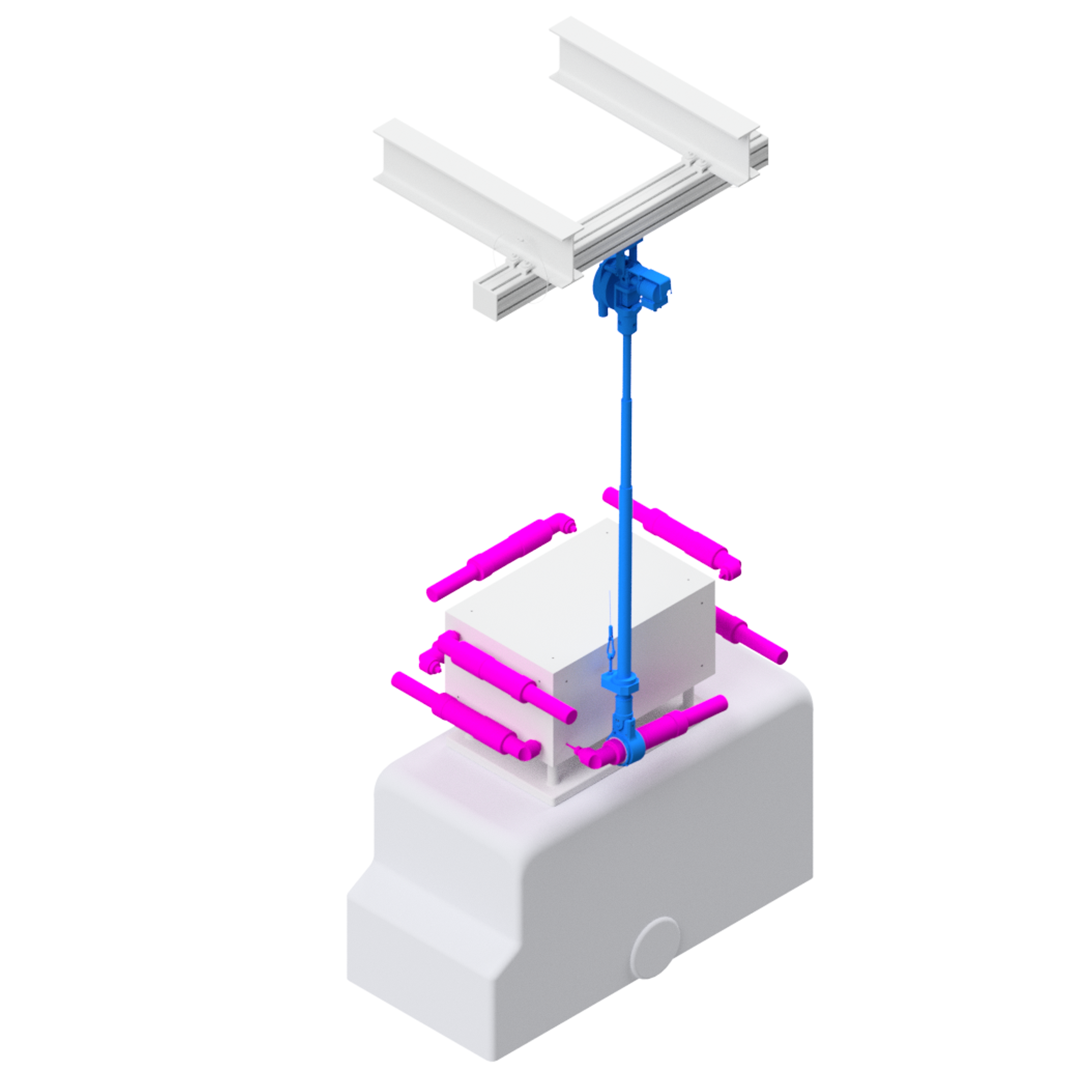

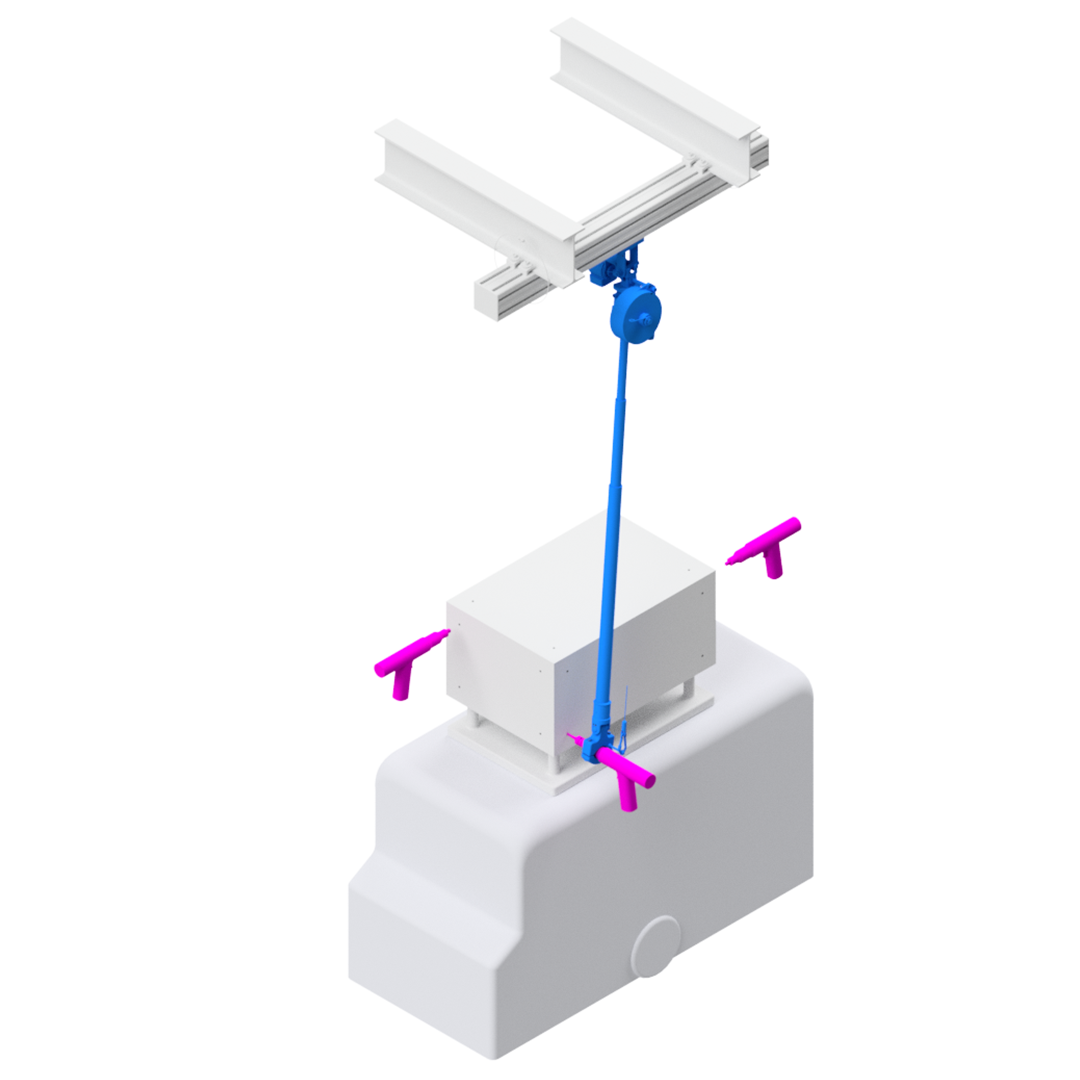

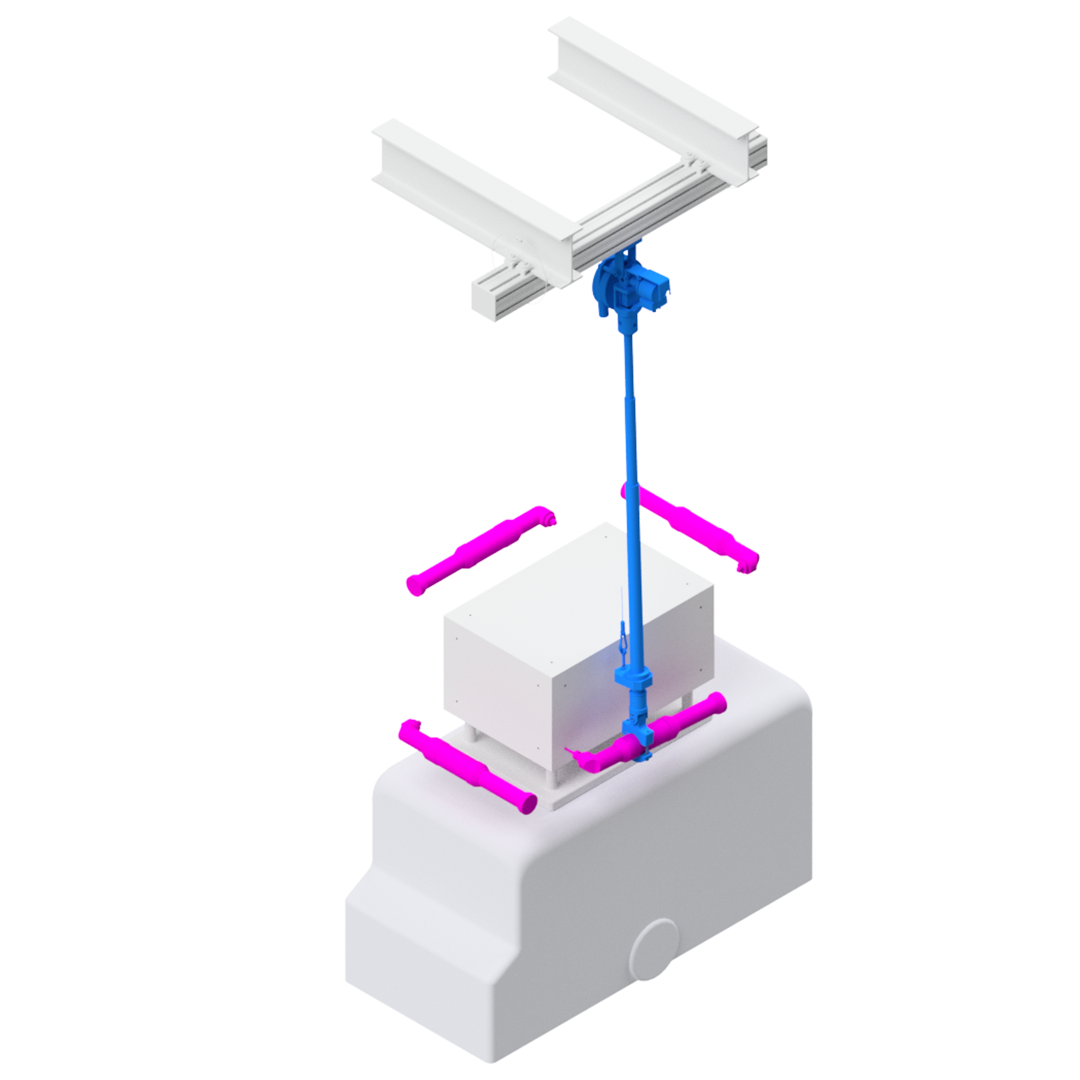

Screwing direction vertical

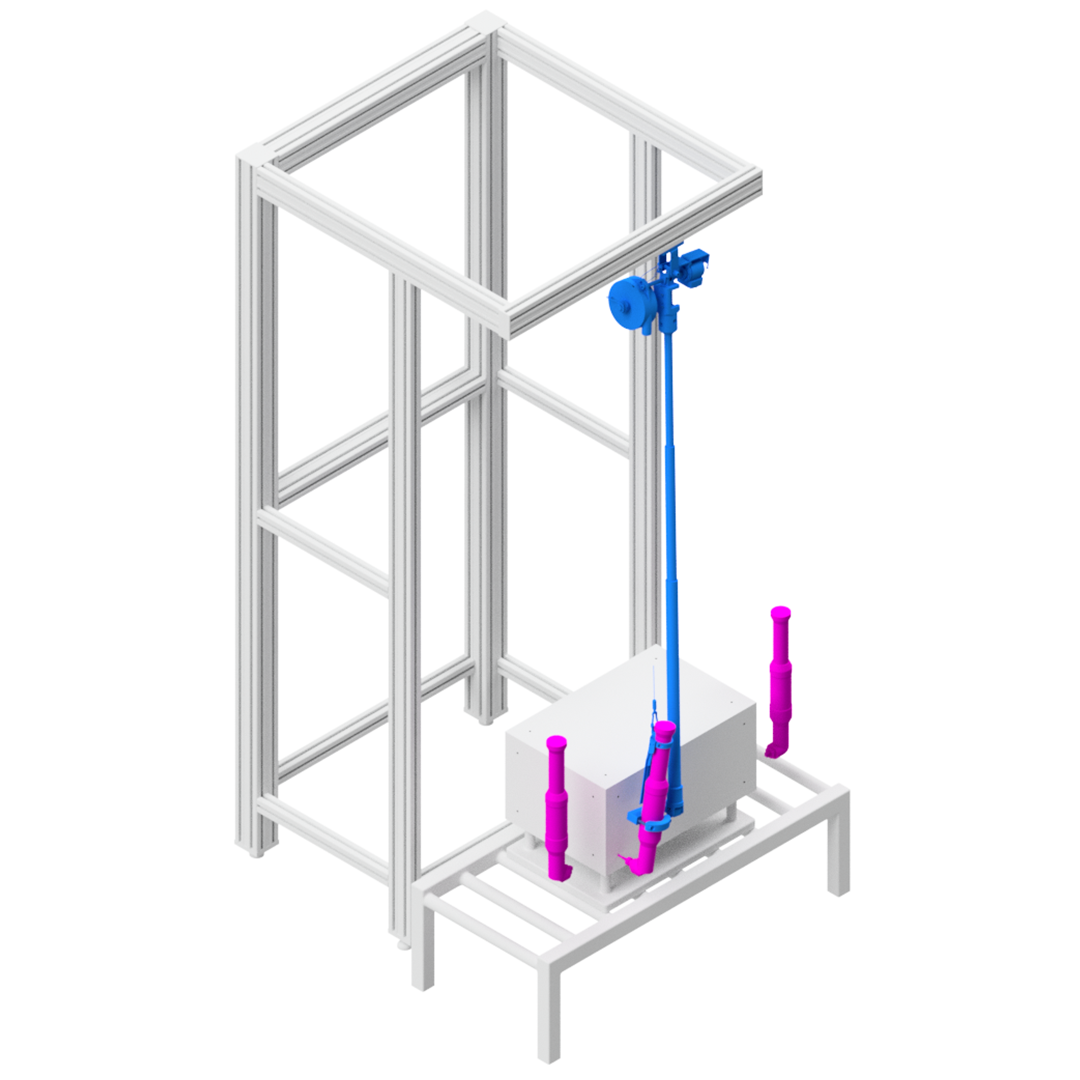

Screwing direction Horizontal FTS

Product advantages

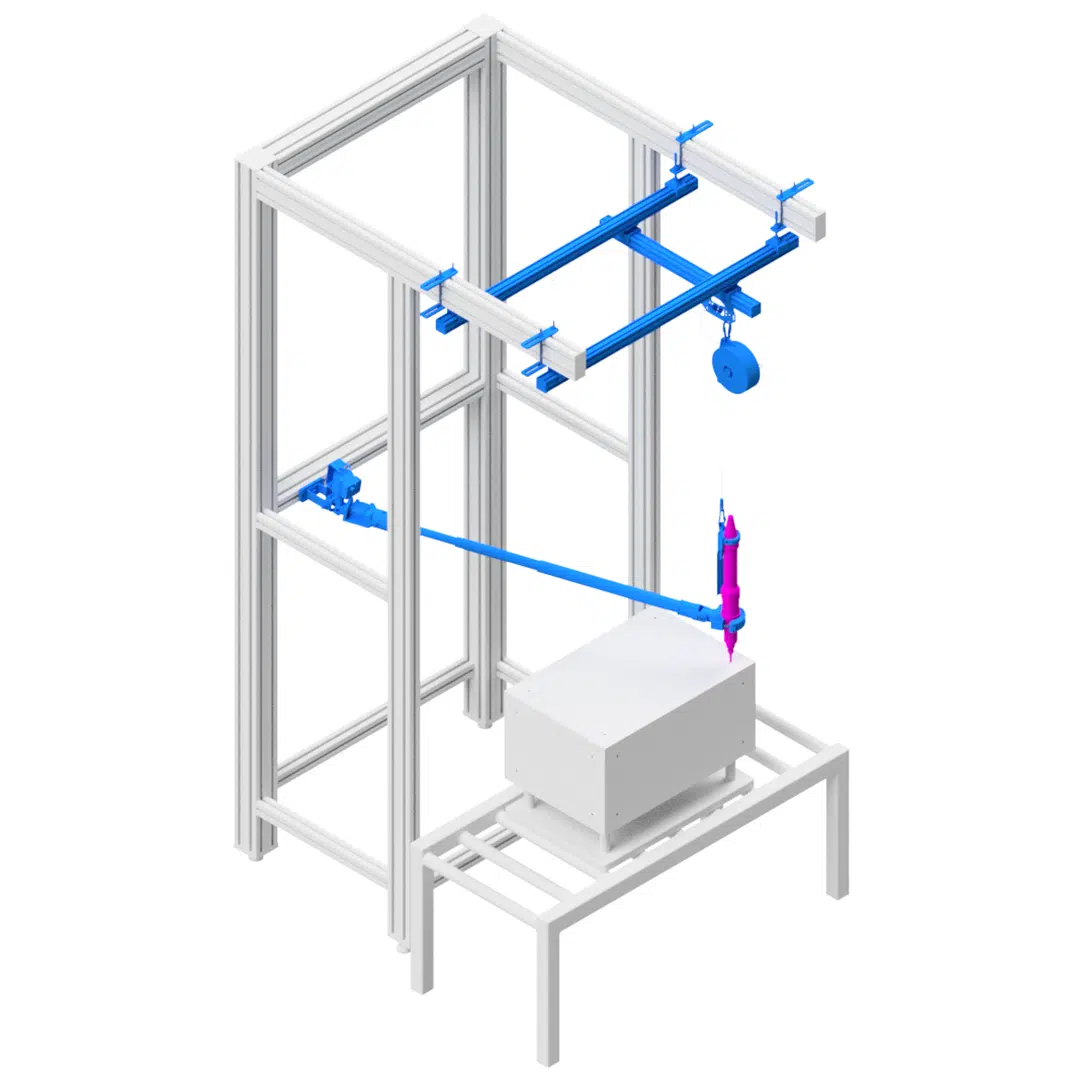

System design & flexibility

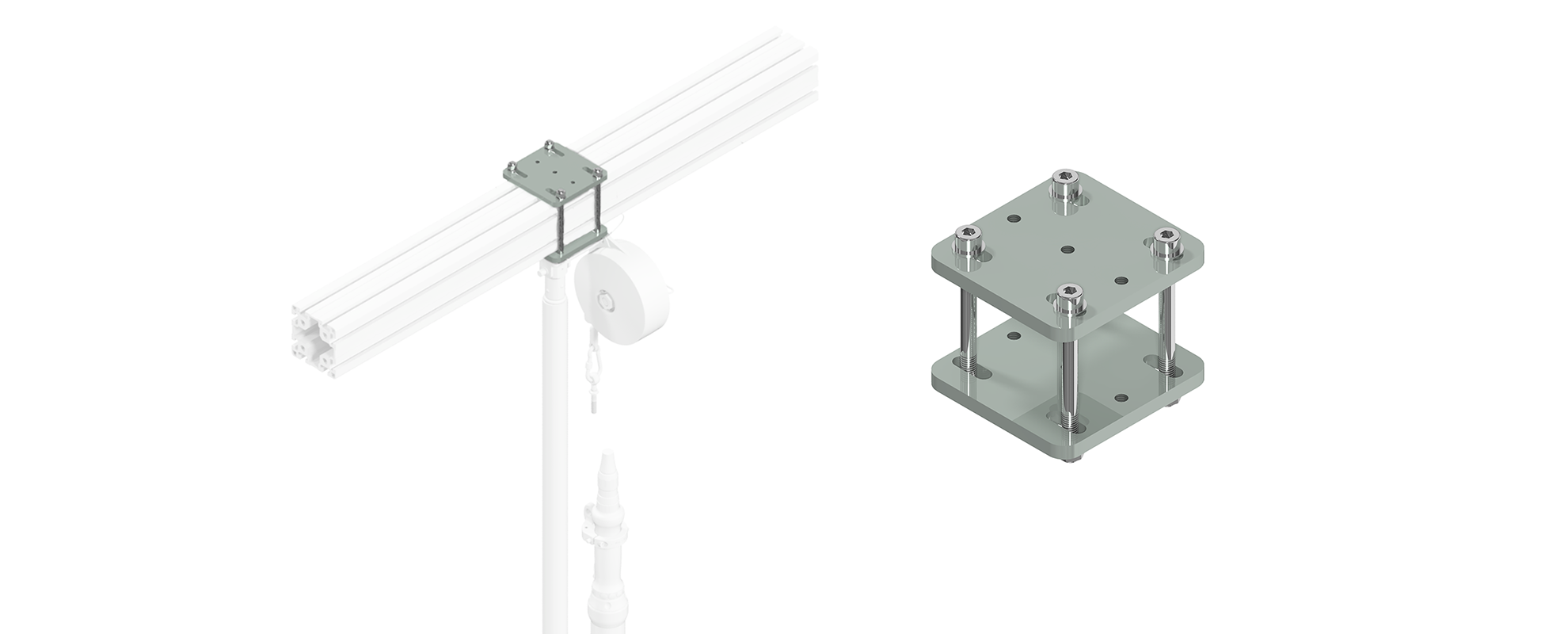

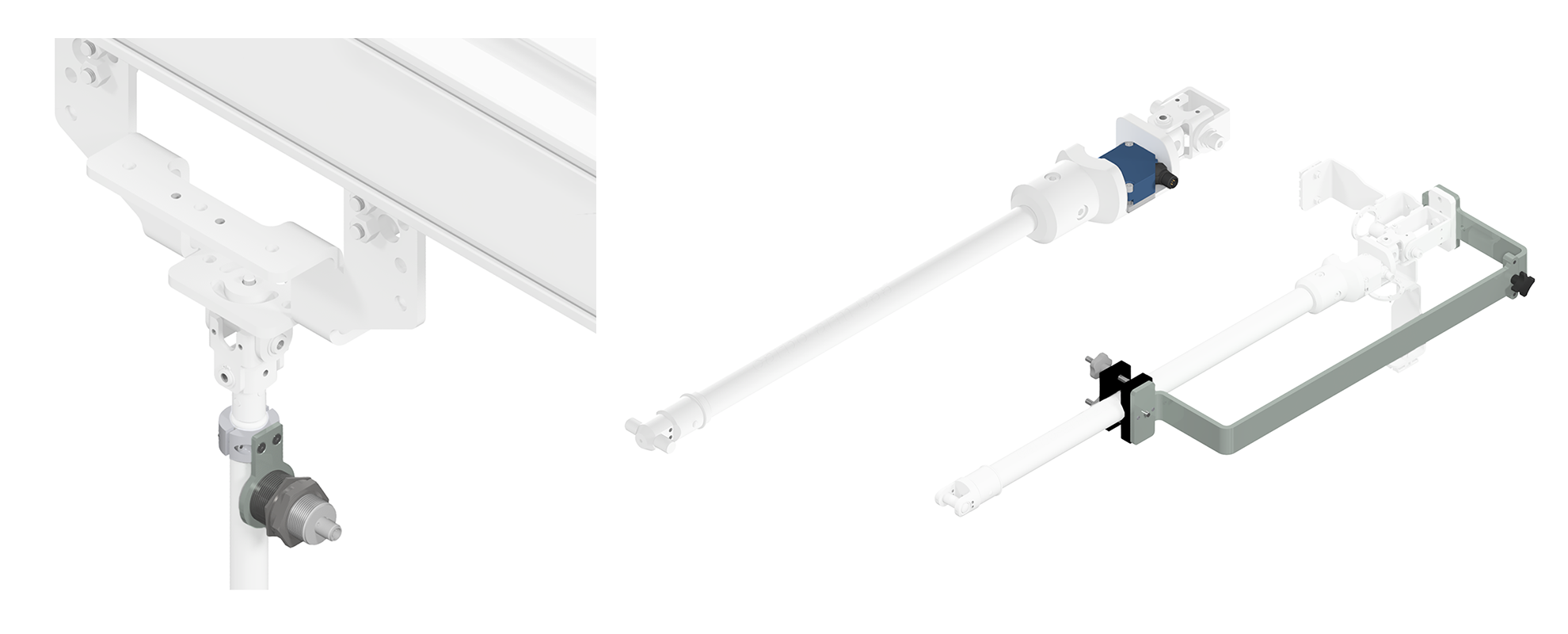

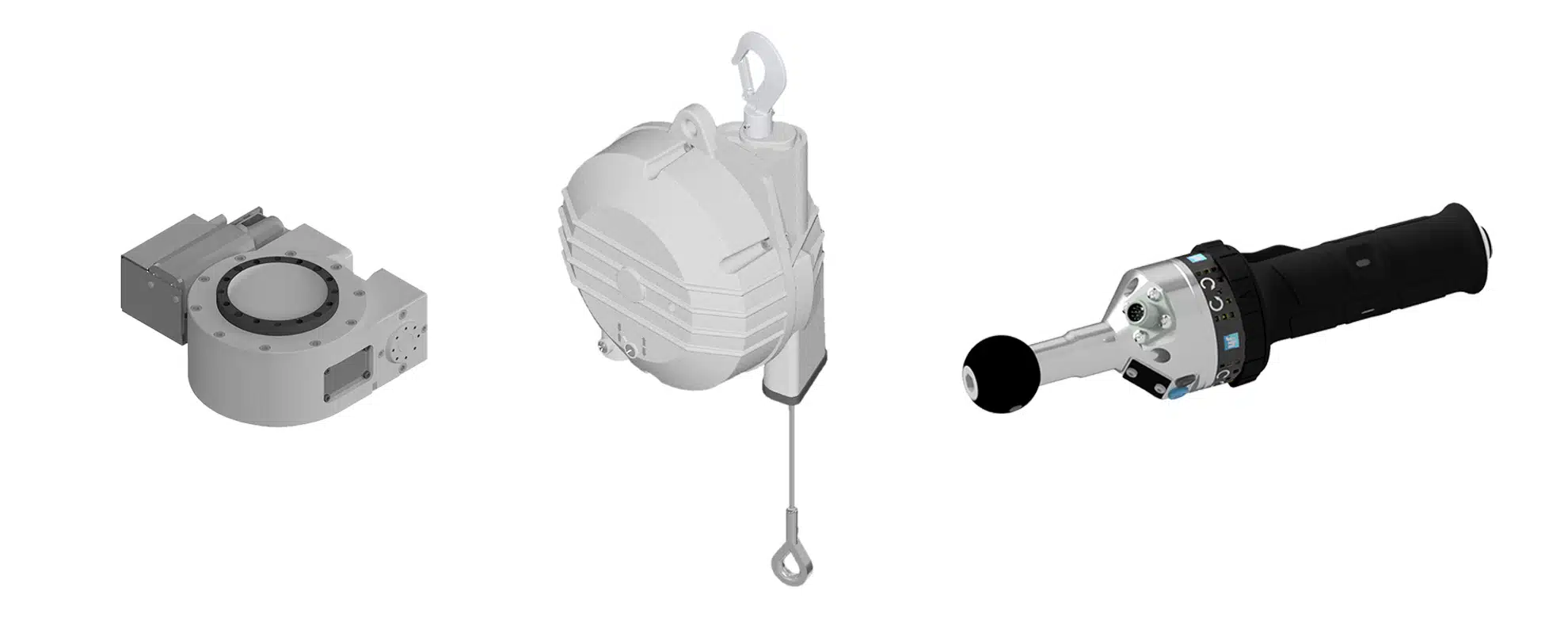

Rear interface: Cardanic connection

Front interface: rod end for tool holders

Performance & ergonomics

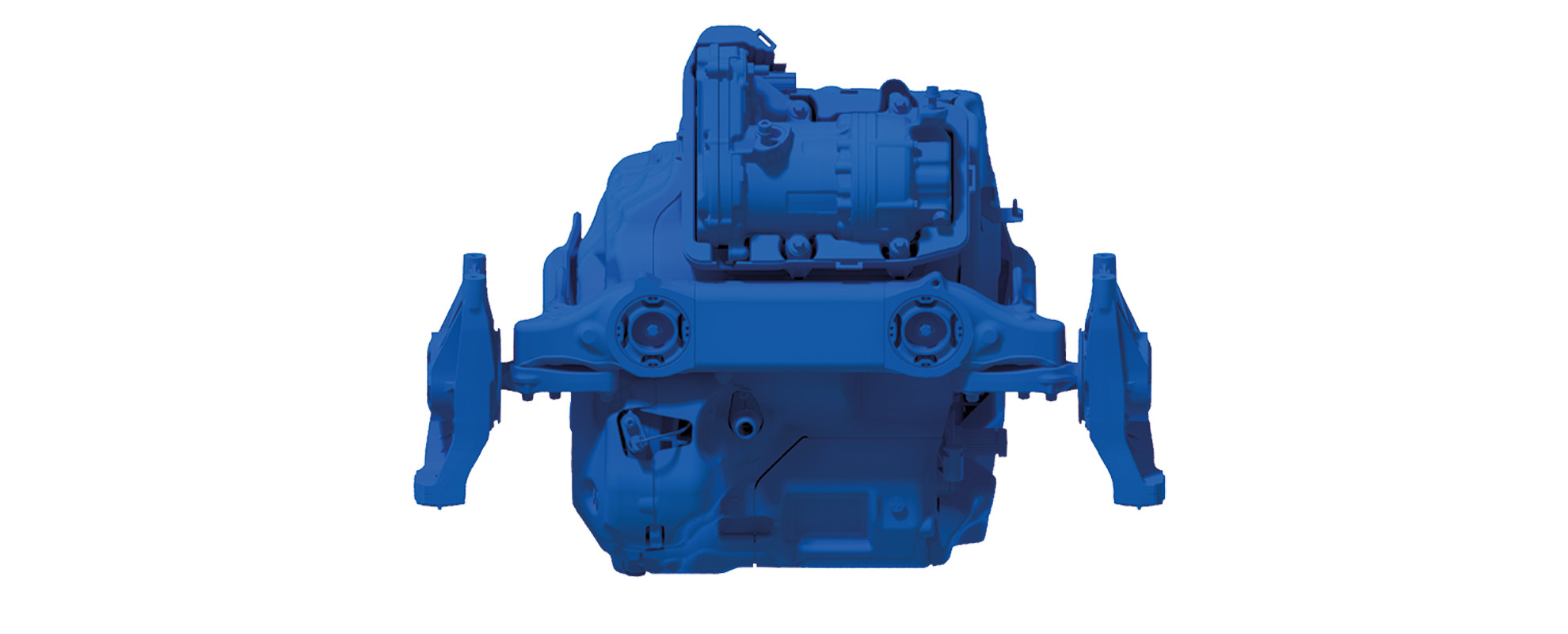

Payloads up to 13.15kg

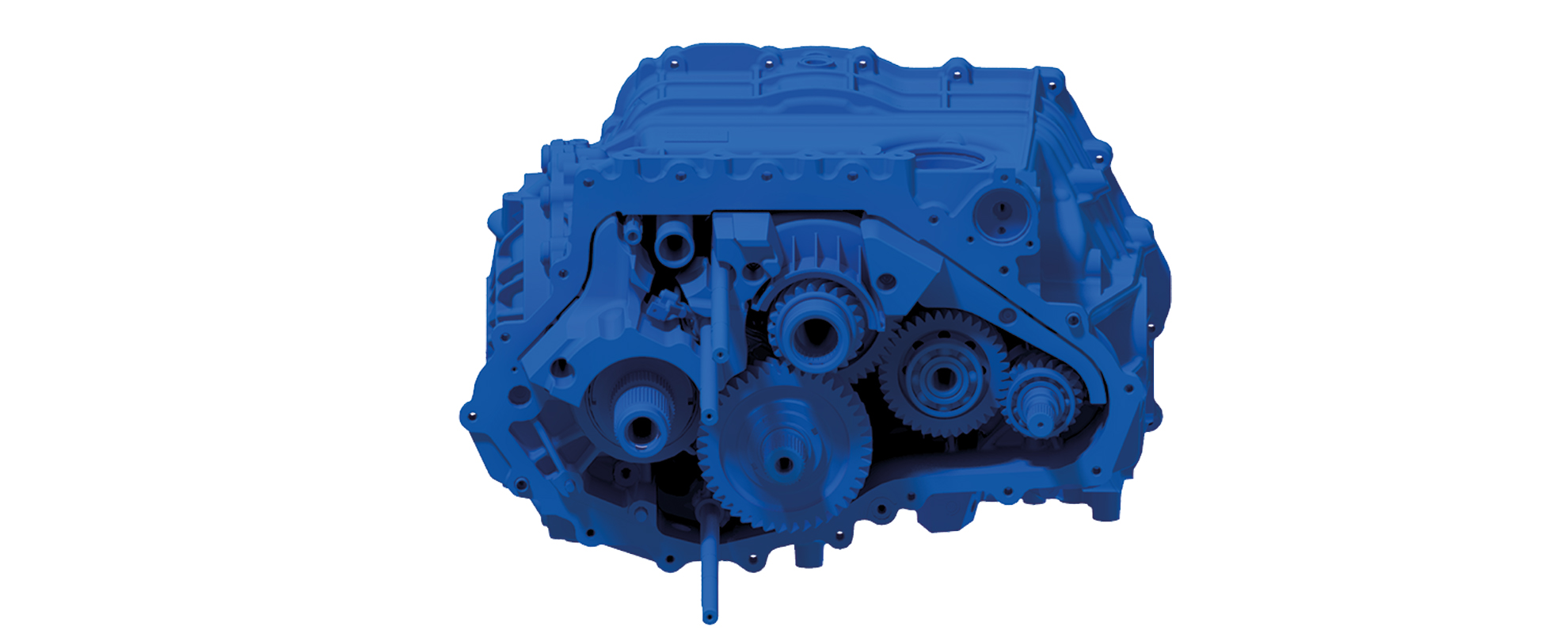

Torque support up to 400Nm

Working range up to 3148mm

Process integration & operational safety

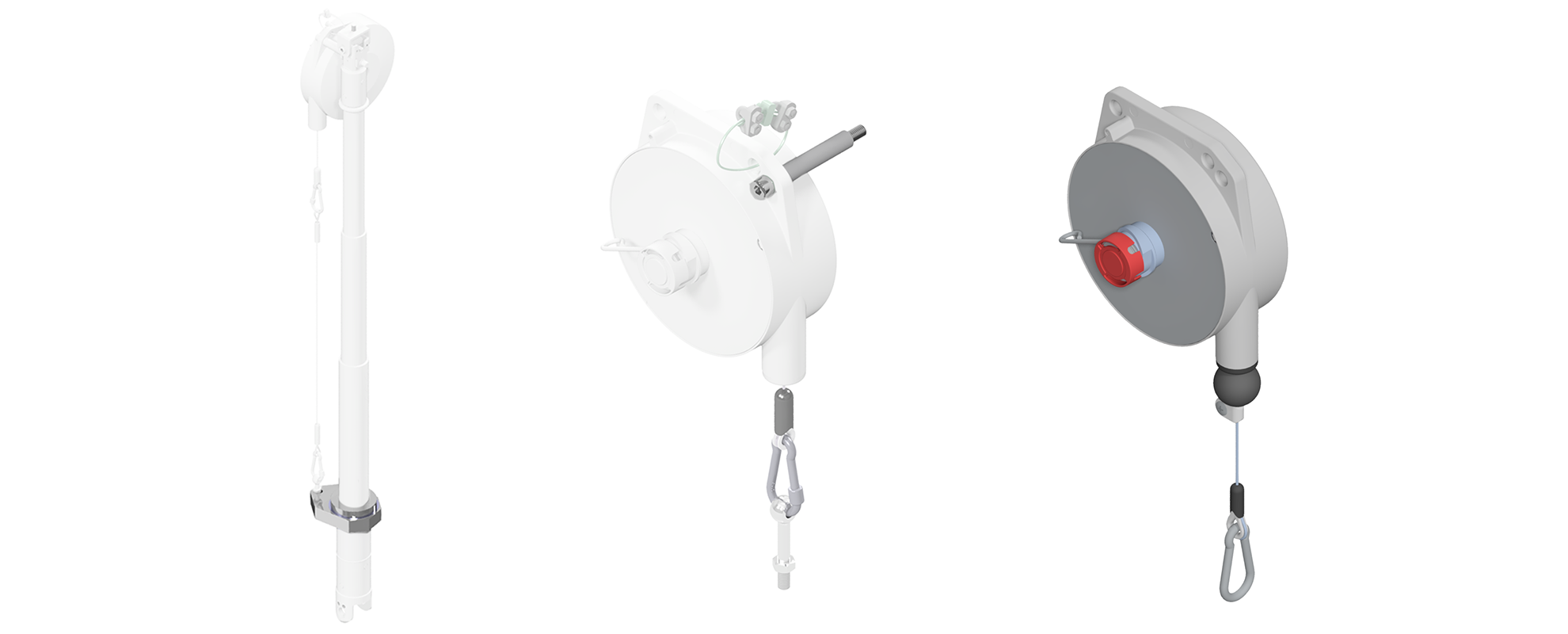

Maintenance-free 3-fold telescopic pull-out made of carbon fiber

Series

Lmin

Lmax

* As the stroke increases, the maximum payload and transferable torque decrease.