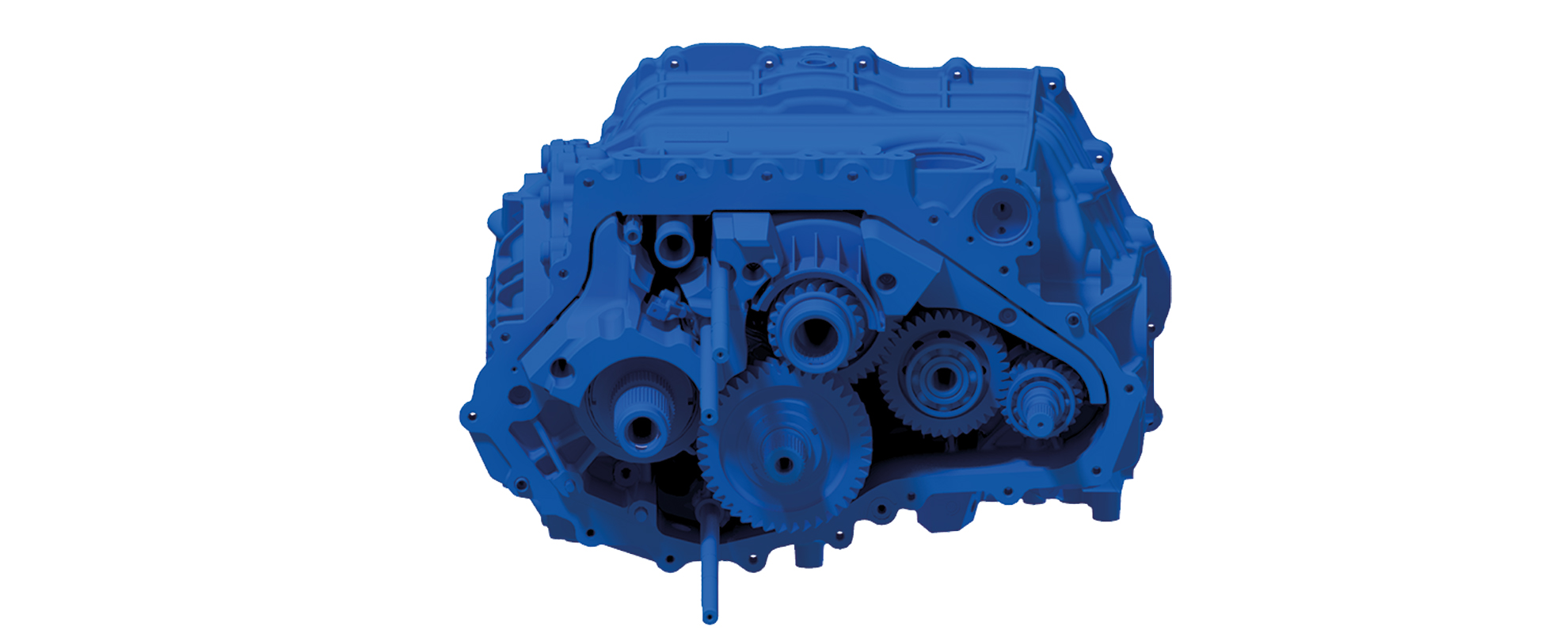

Our specially developed, backlash-free, and galvanically isolated drives can be used with insulated sockets and bits via an integrated quick-change chuck. They are particularly suitable for hand-guided screwdriving with position monitoring and are primarily used in battery assembly. The backlash-free drive ensures that even very closely spaced screw locations can be reliably distinguished with long bits in accordance with the zero-defect strategy. The galvanic isolation and insulated jacket surface minimize the risk of contact with live components, prevent dangerous short circuits due to high electrical currents, and protect battery modules from accidental short-circuiting.

Product advantages

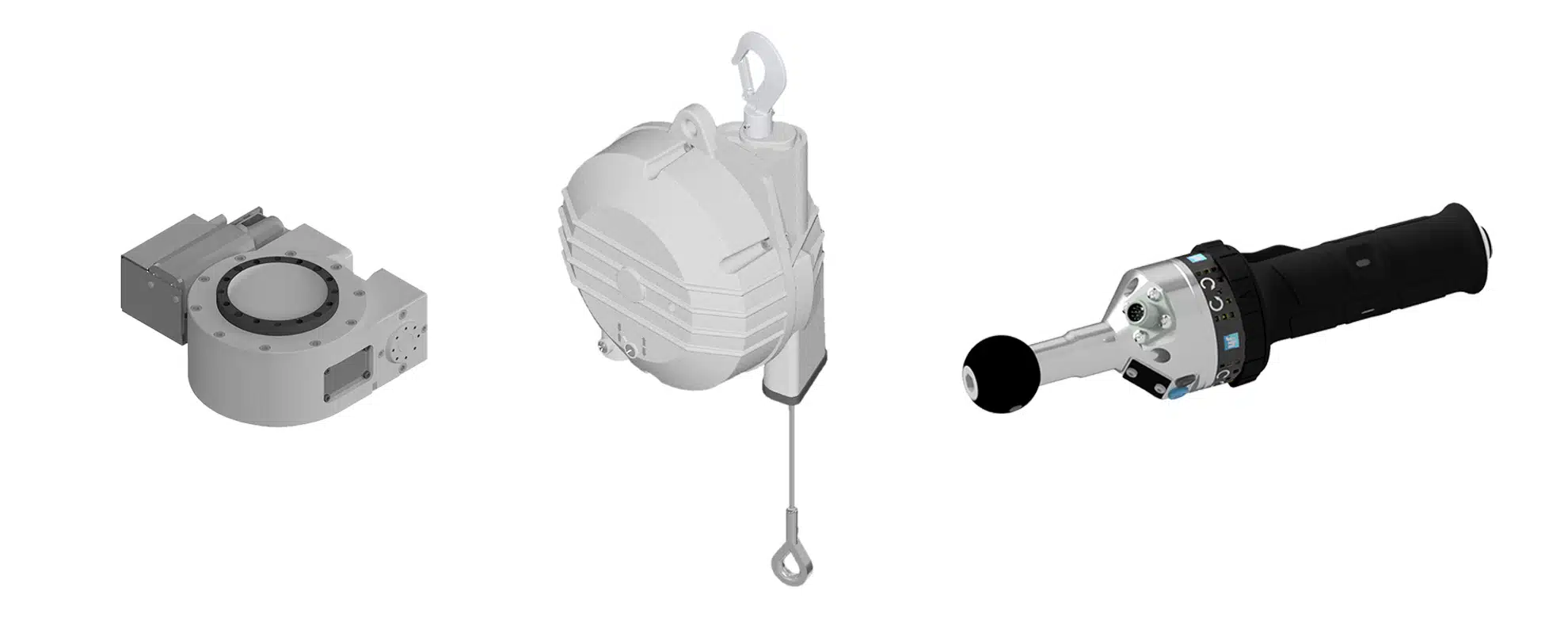

System design & flexibility

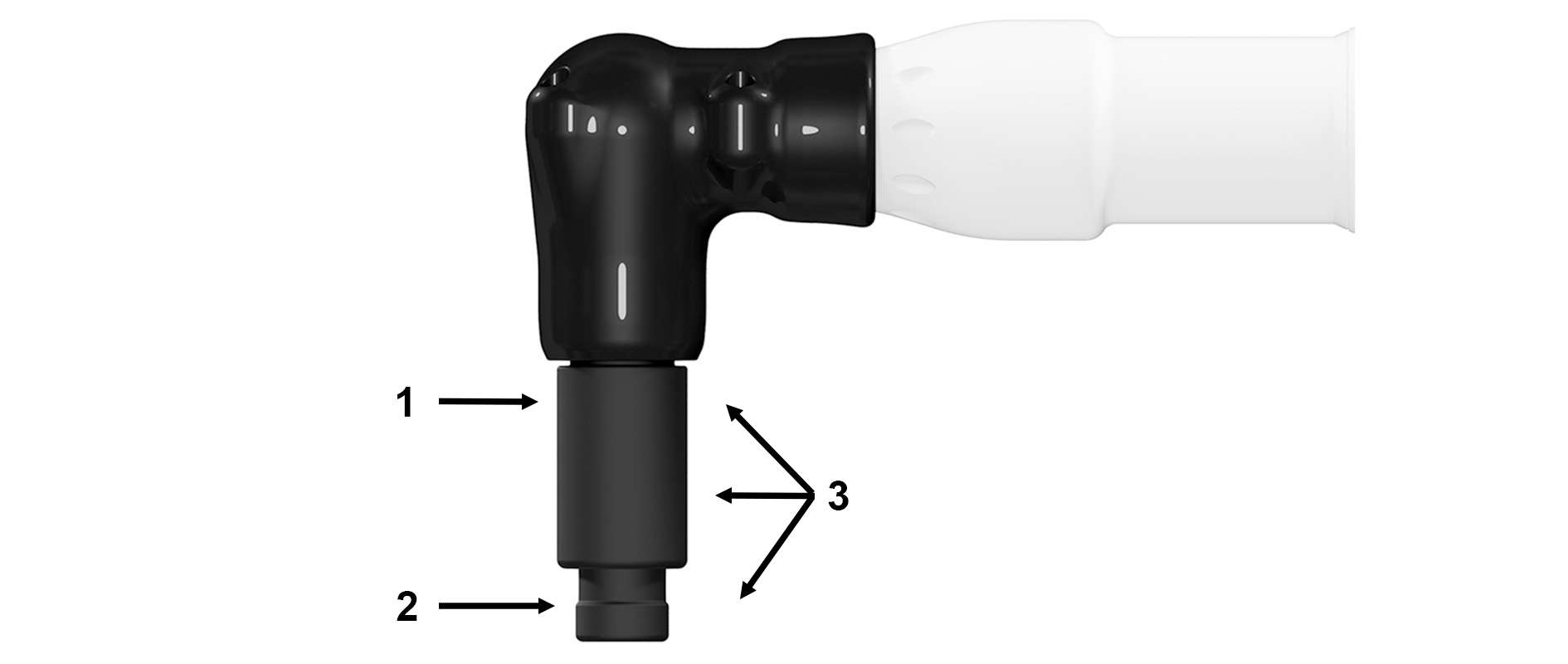

Depending on the variant, commercially available 1/4″ or 7/16″ (DIN 3126 E) bits can be attached

Performance & ergonomics

Process integration & operational safety

Protection of workers and hand screwdrivers or built-in spindles from electrical voltage

Technical properties

Tested in all applicable areas of the DIN EN 50178:1998-04 and DIN EN 62477-1:2017-10 standards

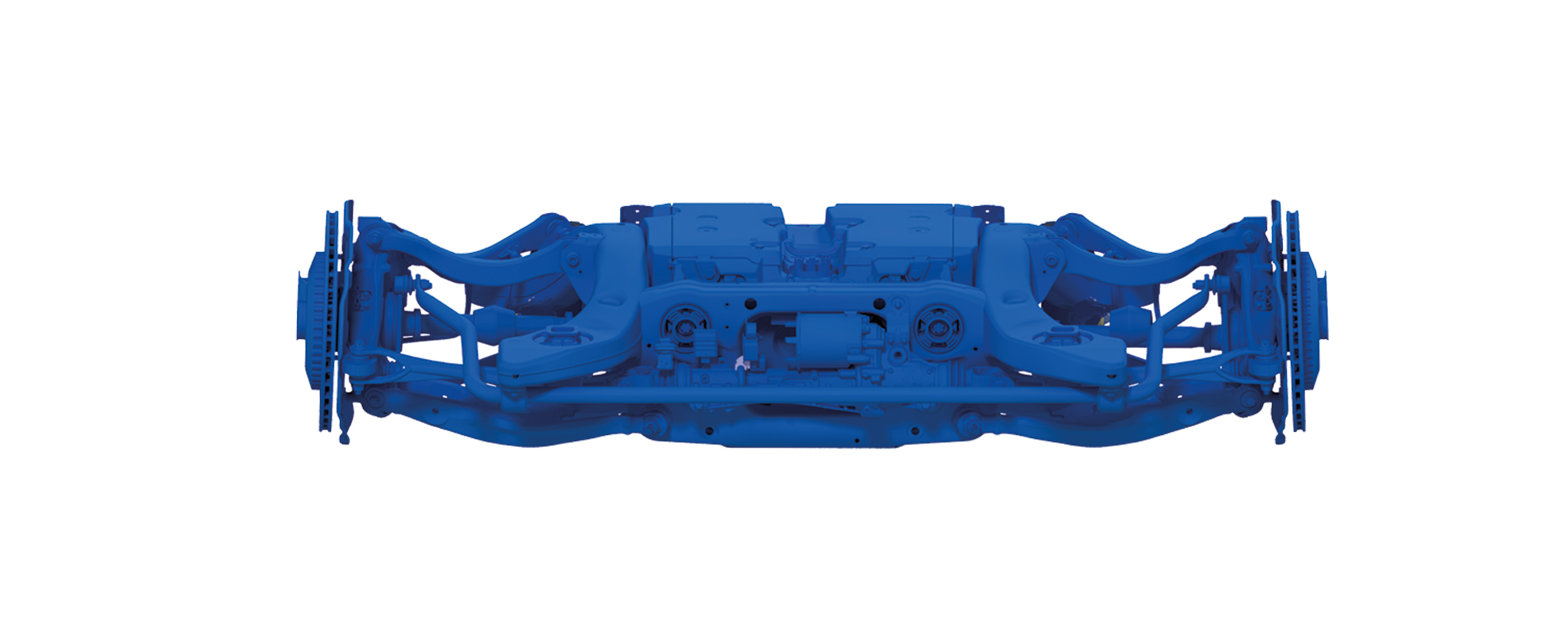

Area of application

With position-monitored screwdriving using a JÄGER Handling, the following screw distances can be achieved depending on the product.