Task

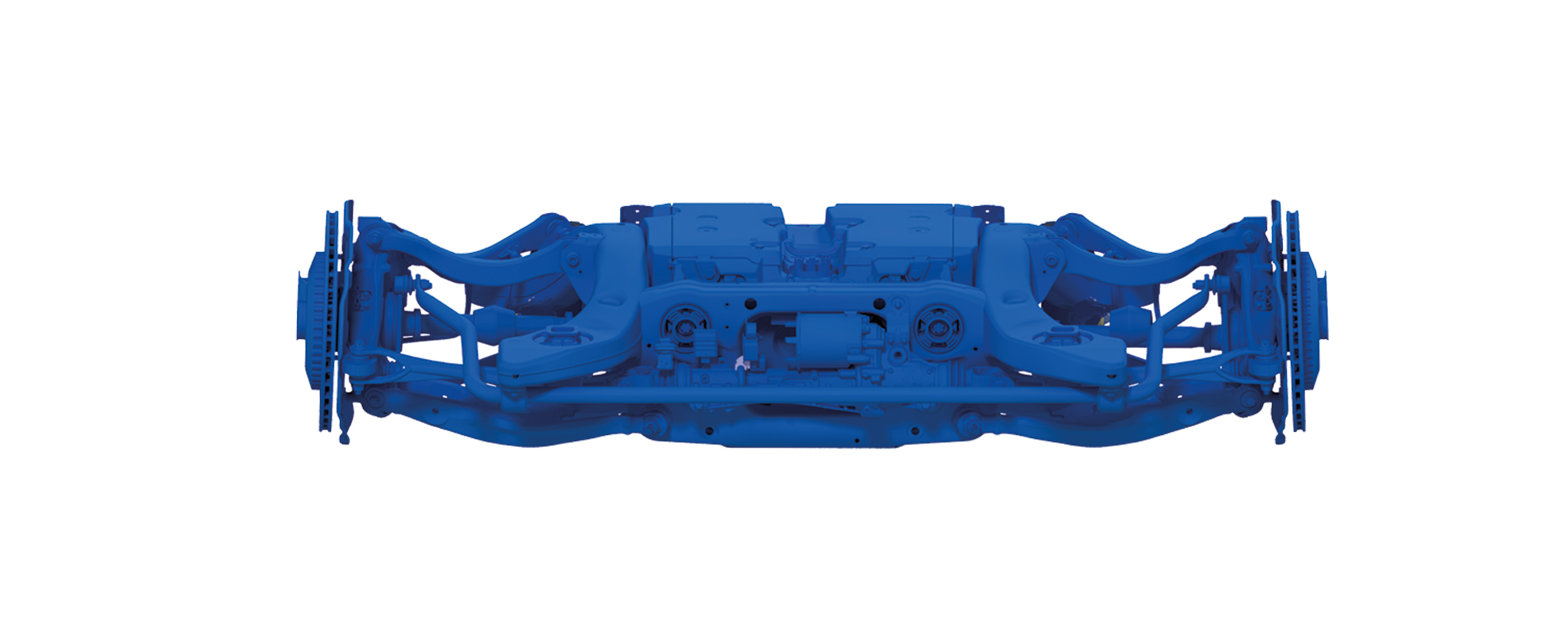

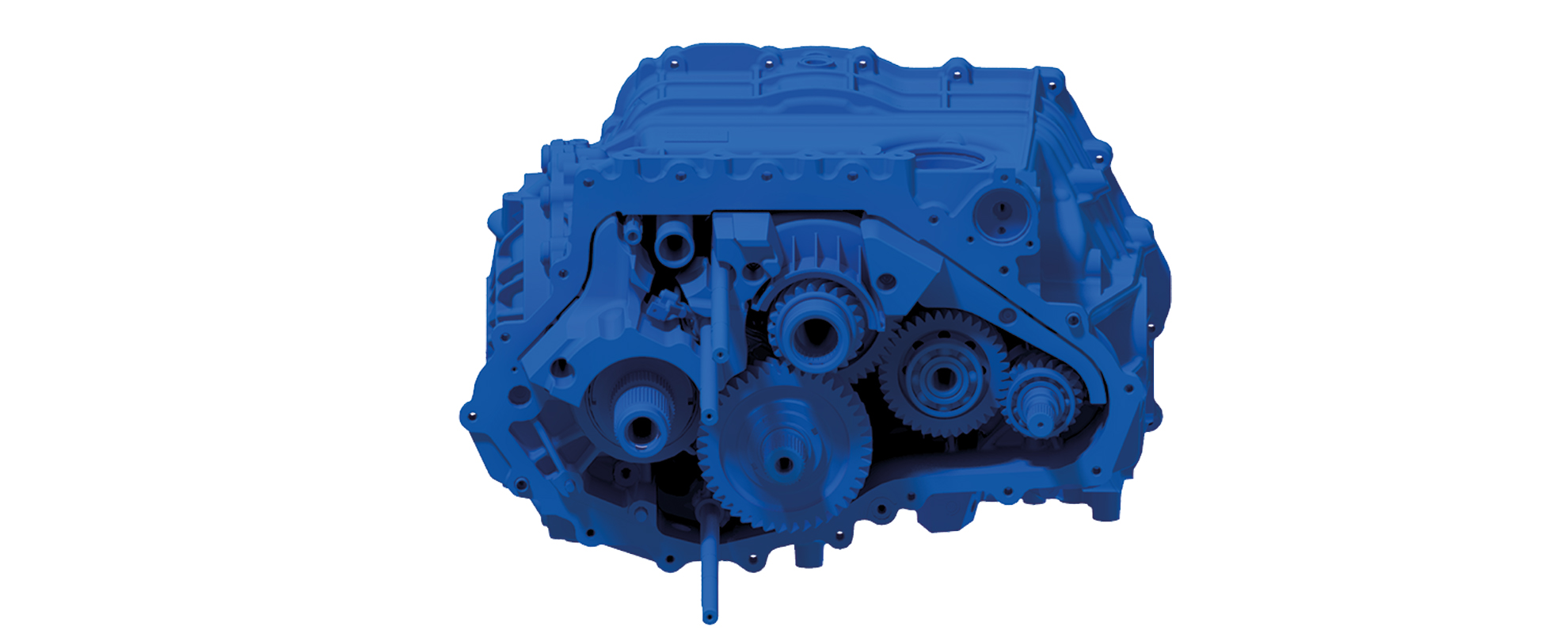

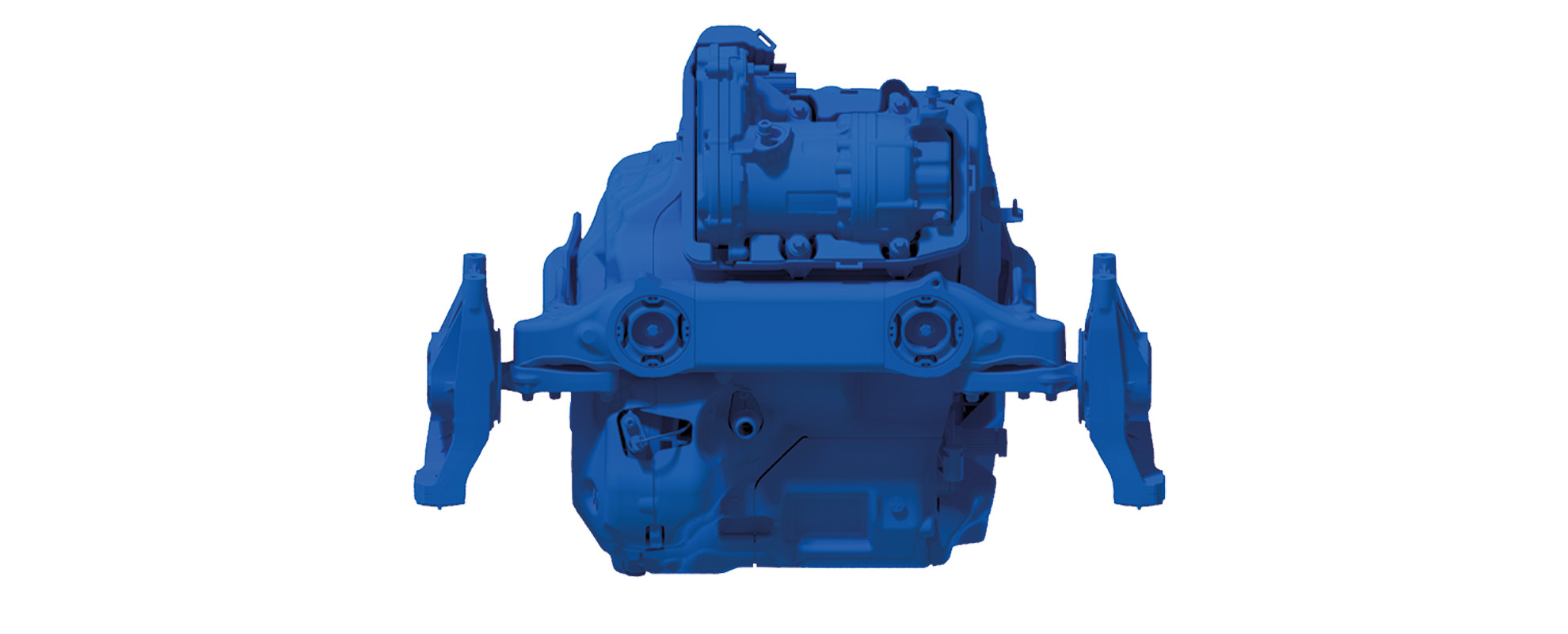

Bolting the support frame to the E-motor. During bolting, the support frame must be fixed to the E-motor by a hold-down device. Initially, bolting is performed with two spindles, followed by two additional bolting operations each with a single spindle. Between the individual bolting operations, the workpiece carrier, including the motor and support frame, must be rotated accordingly to reach the required positions. Additionally, a mobile solution for external reference measurement must be provided.

Special feature: Hold-down device, reference measurement

Torque: 2x 310Nm

Payload: 55 kg

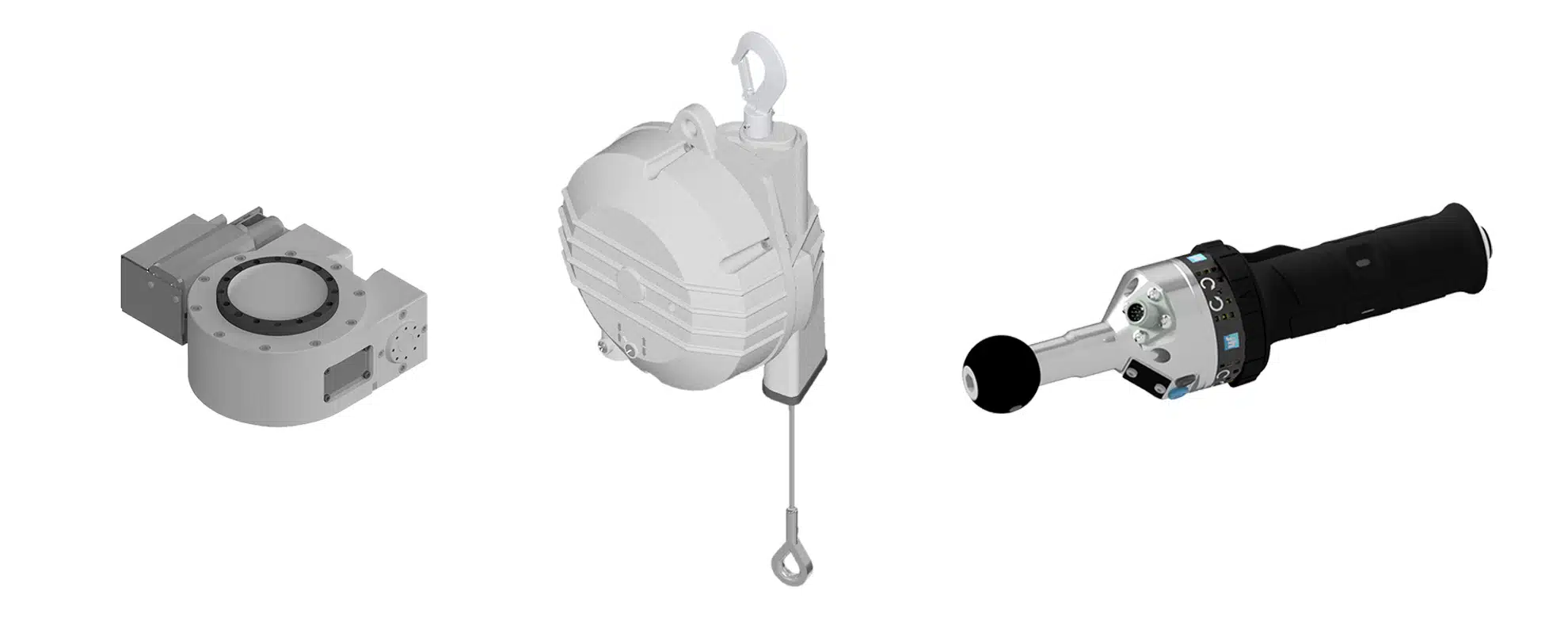

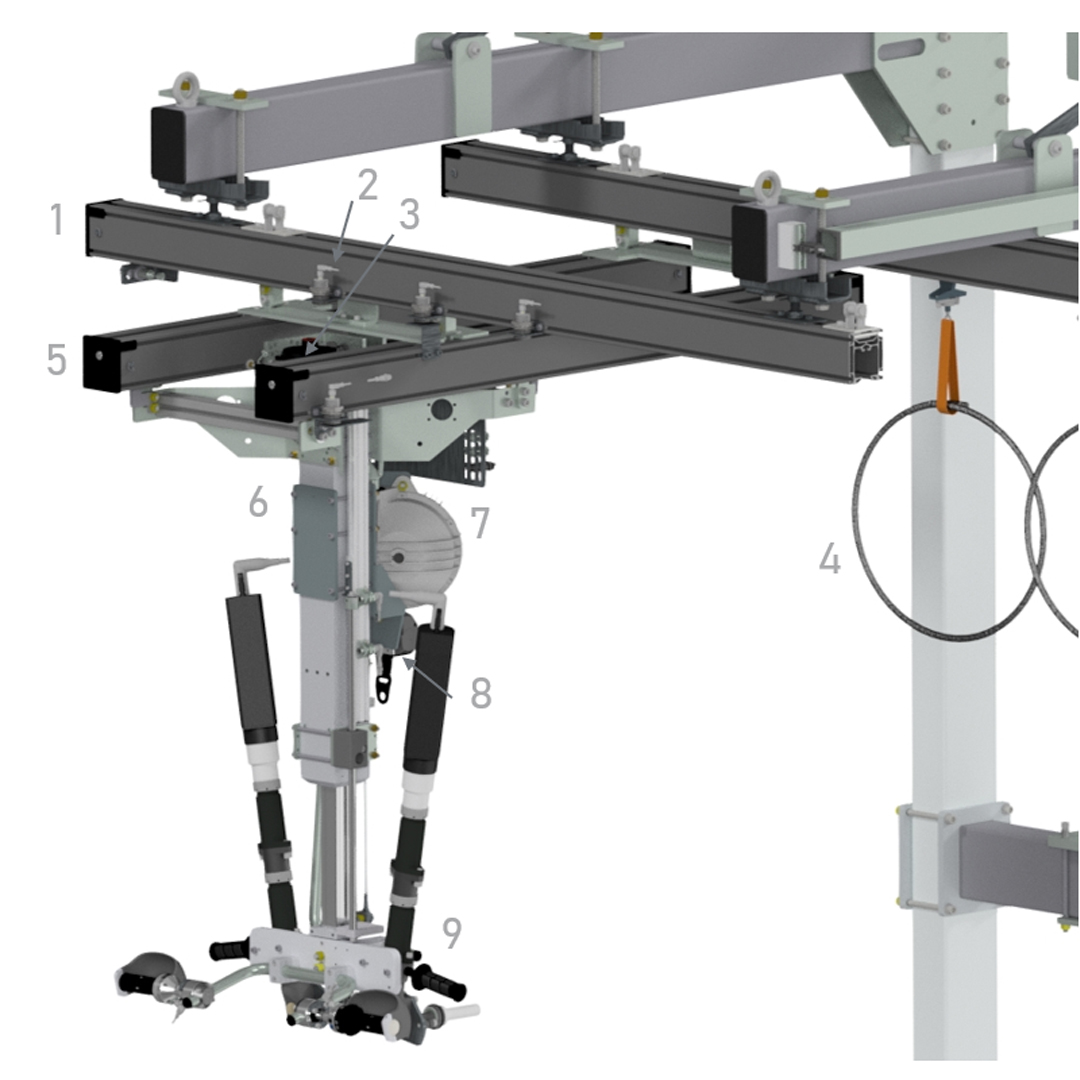

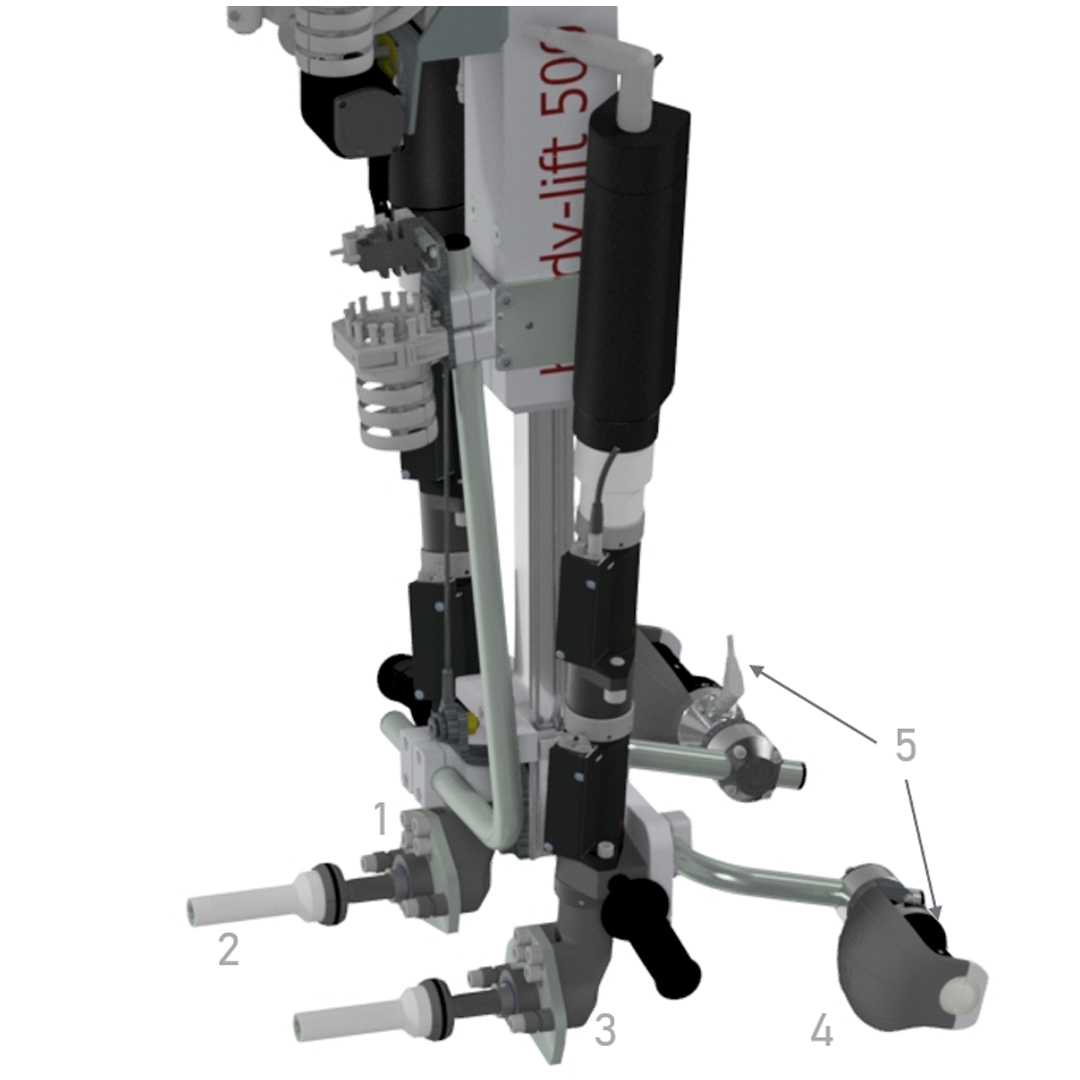

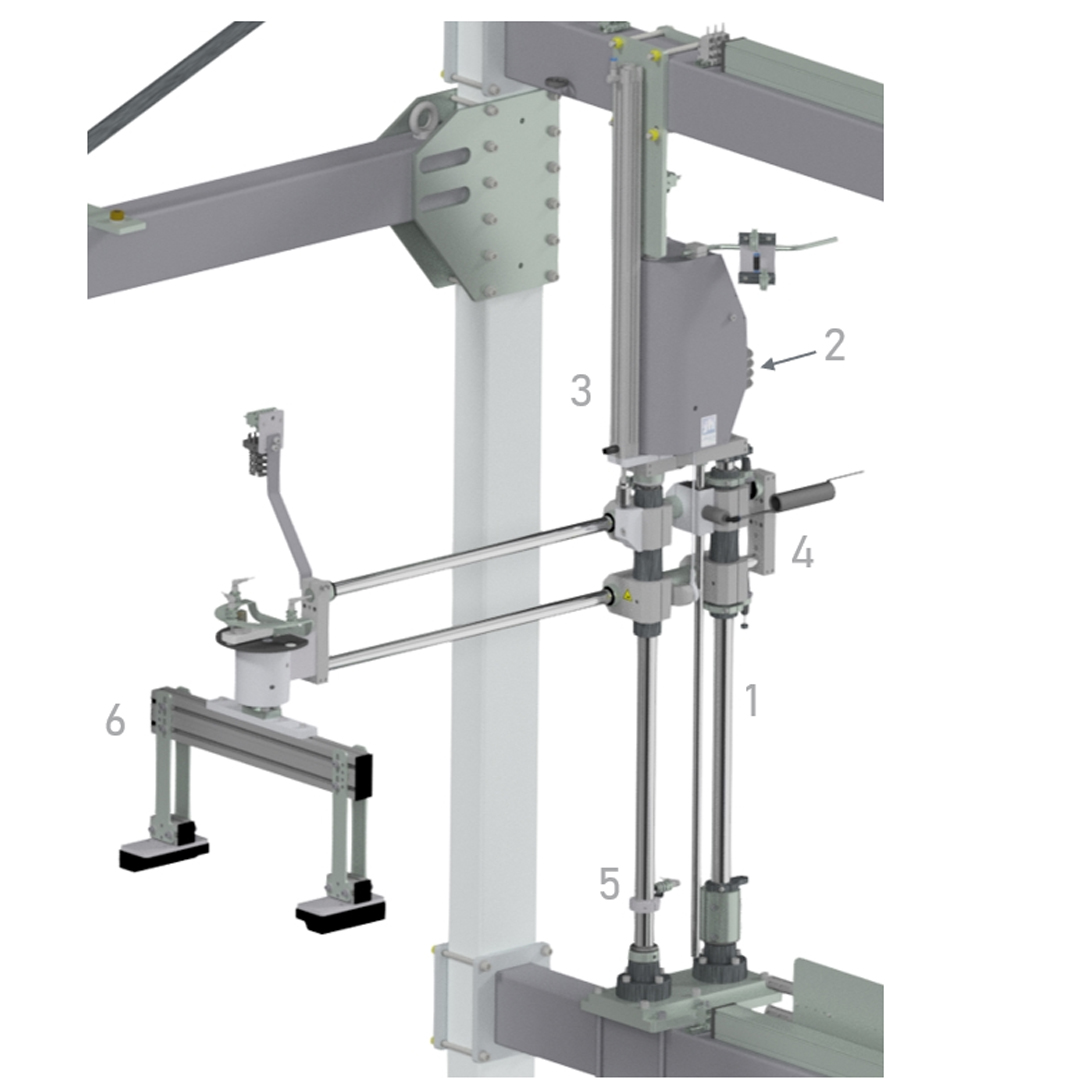

Manual workstation

handy-lift

Adaptation system

handy-flex

Adaptation system

Reference measuring adapters trolley