Reference measurement is an essential process in industrial screwdriving technology, which is used in both electrically controlled spindles (EC spindles) and hand-held screwdrivers. It is used for calibration and to ensure the accuracy and precision of the screwing processes. Regular reference measurements ensure that each screw connection exactly meets the specified specifications, which is of great importance, especially in safety-critical industries such as the automotive industry.

What is a reference measurement and why is it important?

Precision | Repeatability

In order to ensure consistent quality in production, EC-spindles and handheld screwdrivers work precisely and reproducibly. Reference measurements help to determine the position and torque can be precisely controlled.

Quality assurance

Faulty screw connections can lead to serious problems. Due to the calibration of the tools ensures that all screws are tightened correctly, increasing the quality and safety of the end products. safety of the end products.

Error detection | -prevention

Regular reference measurements enable the early detection of deviations and errors. This helps to avoid expensive reworking and production downtime.

Compliance with industry standards

Compliance with quality standards and norms, such as ISO/TS 16949 in the automotive automotive industry, requires precise and documented calibration processes.

Product advantages

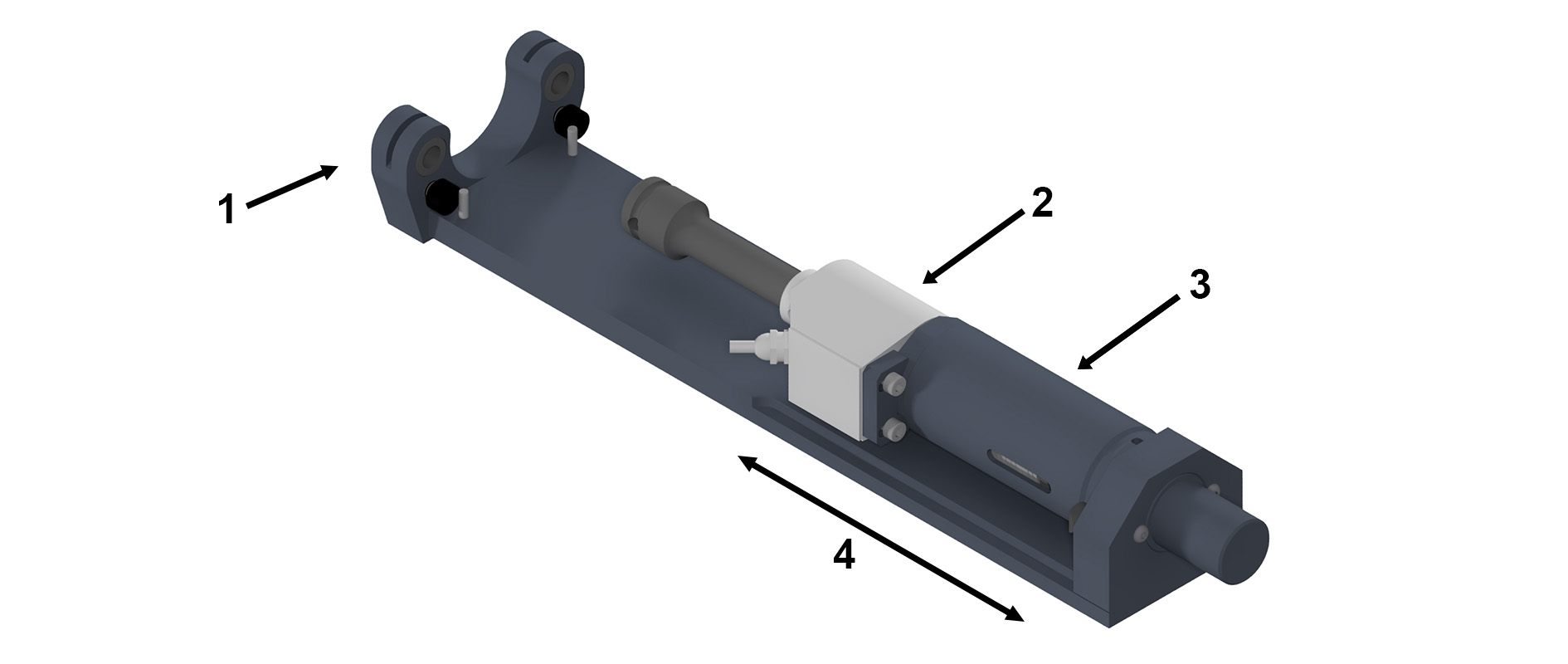

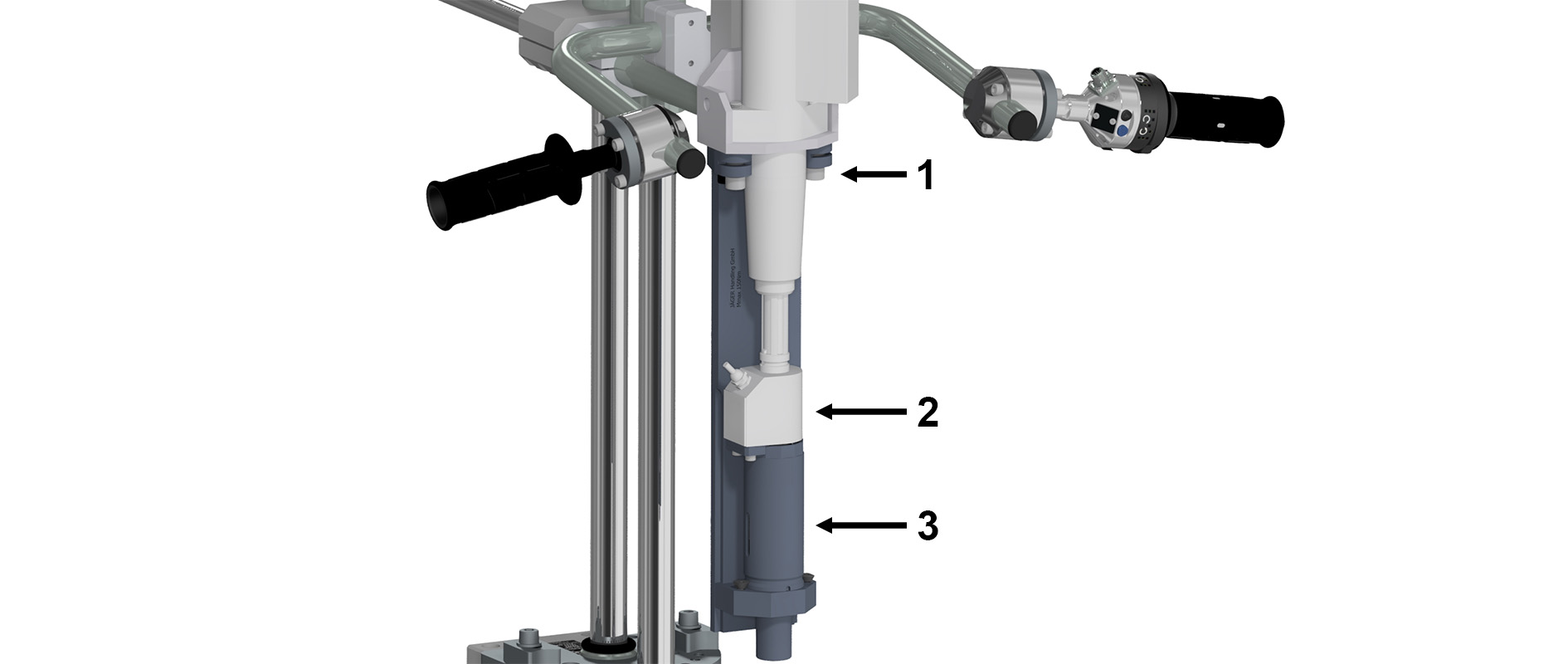

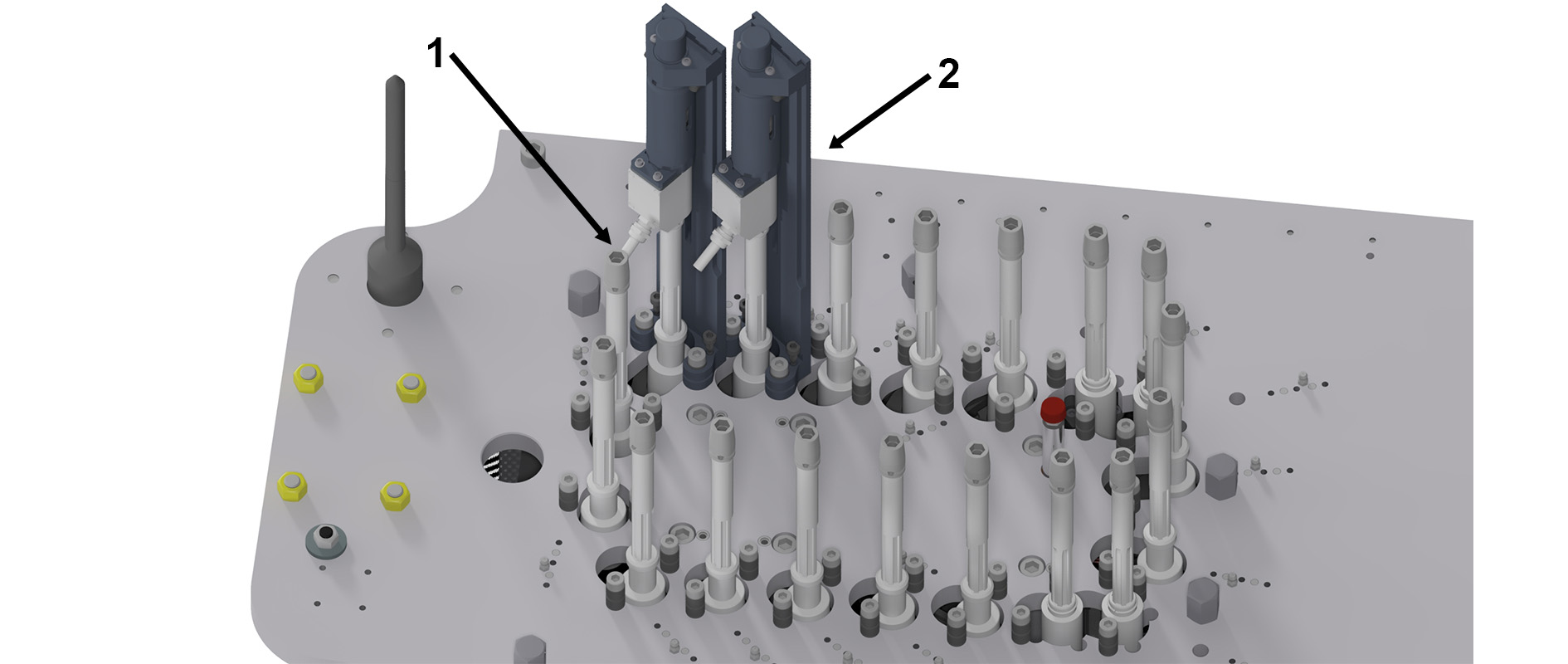

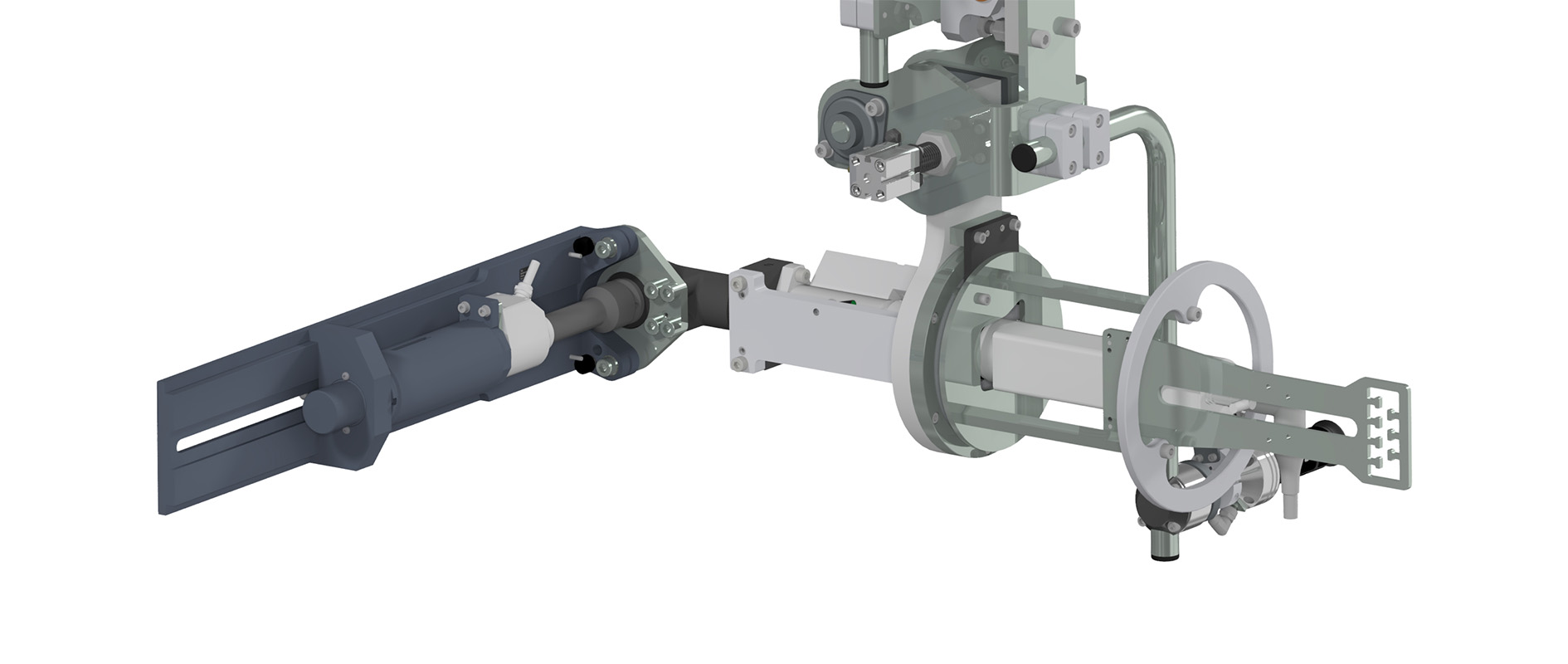

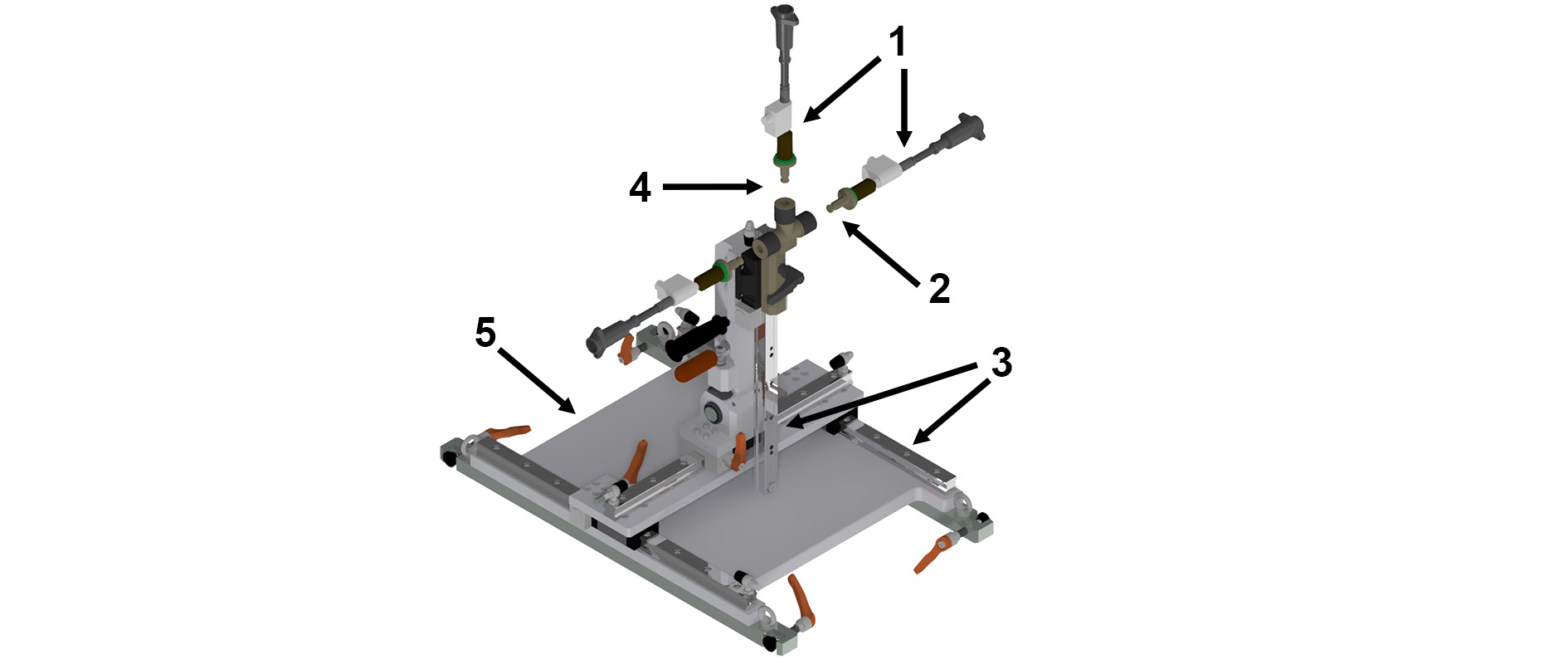

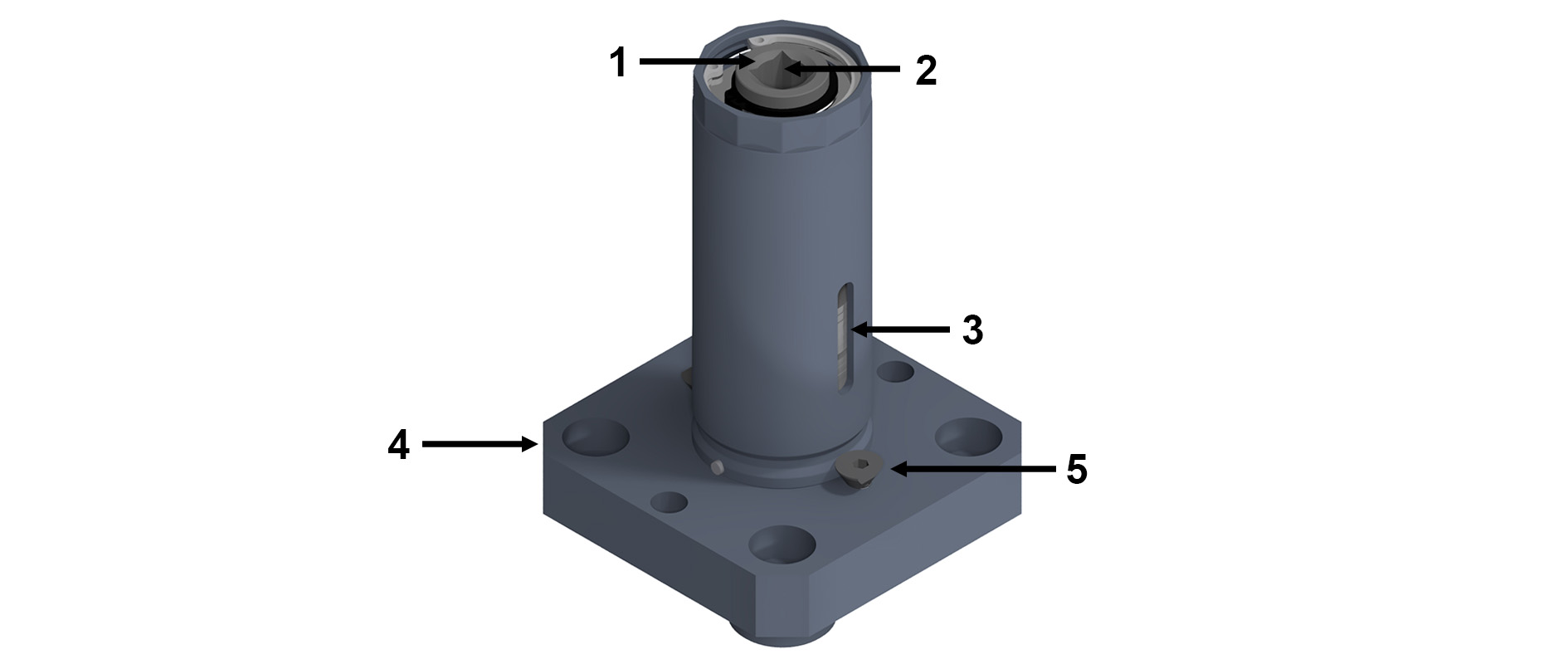

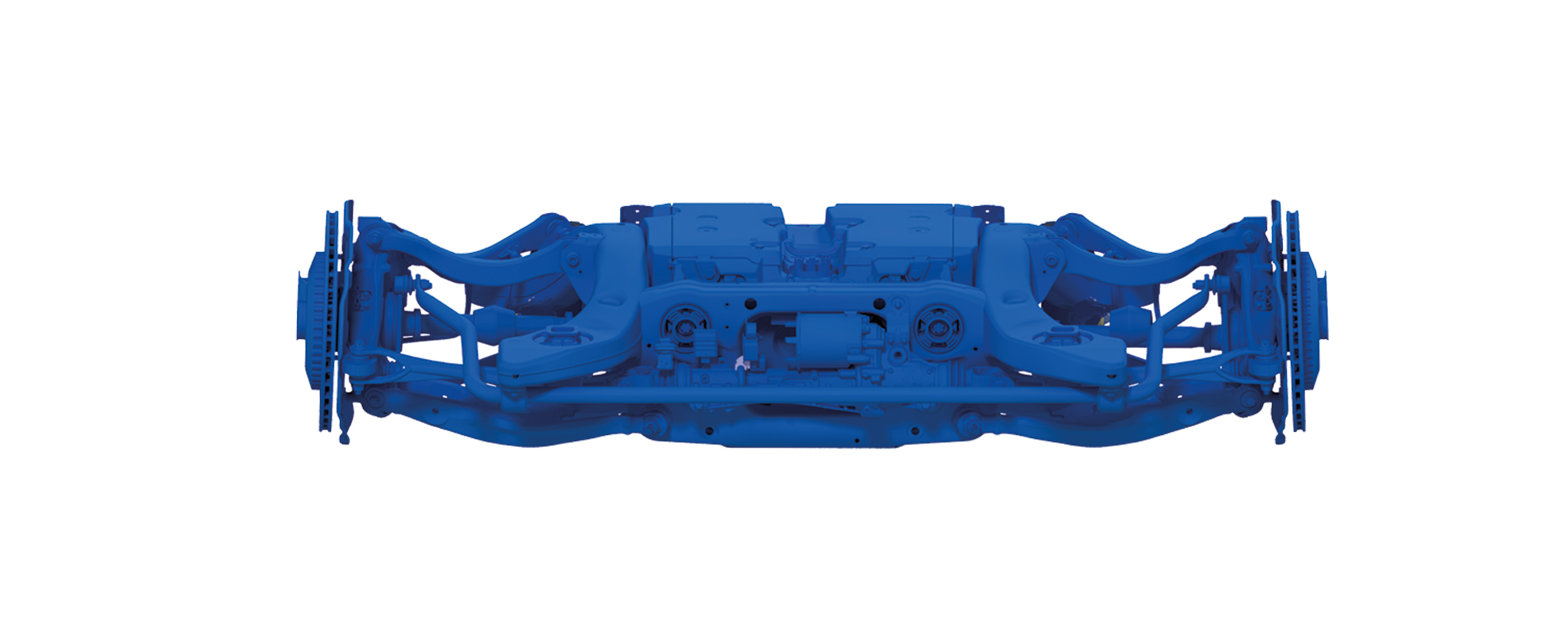

System design & flexibility

Very compact design, therefore also suitable for multi-spindle applications

Screw case adapter for different output output lengths infinitely adjustable

Performance & ergonomics

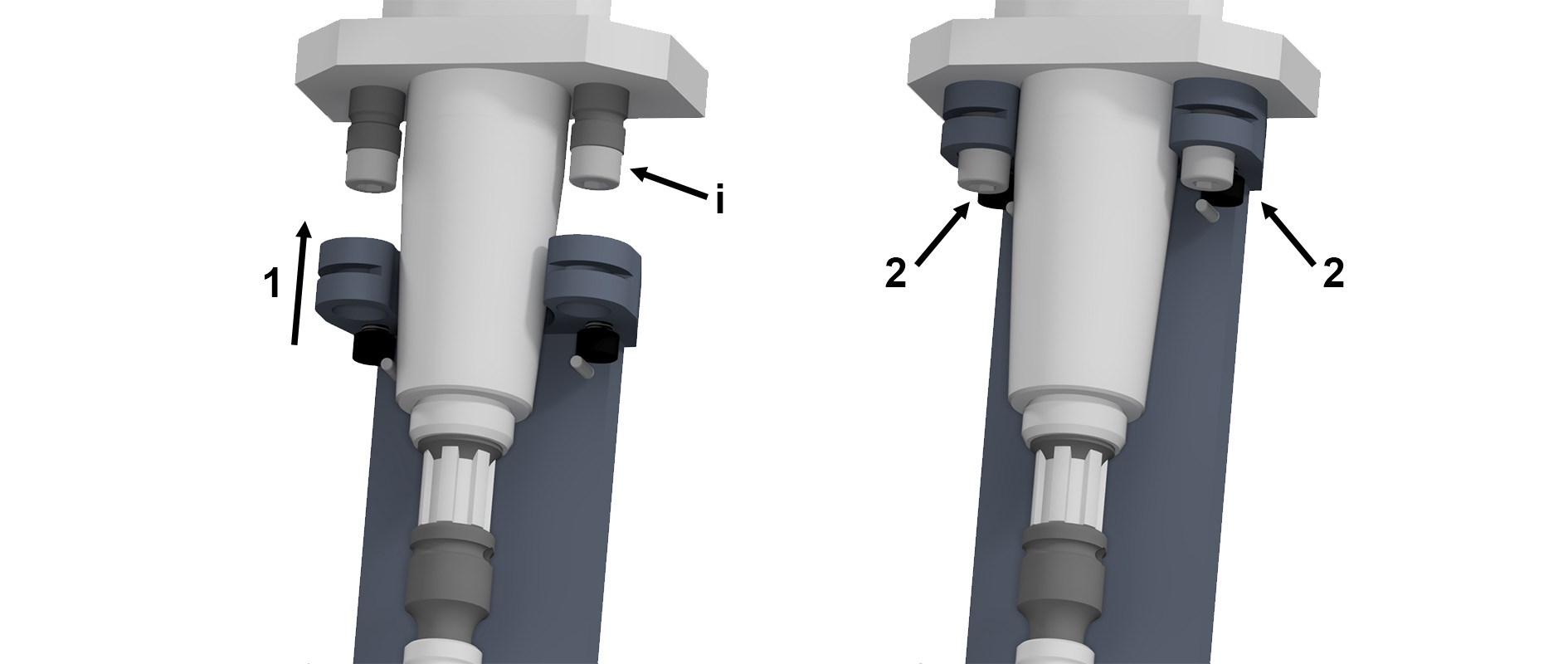

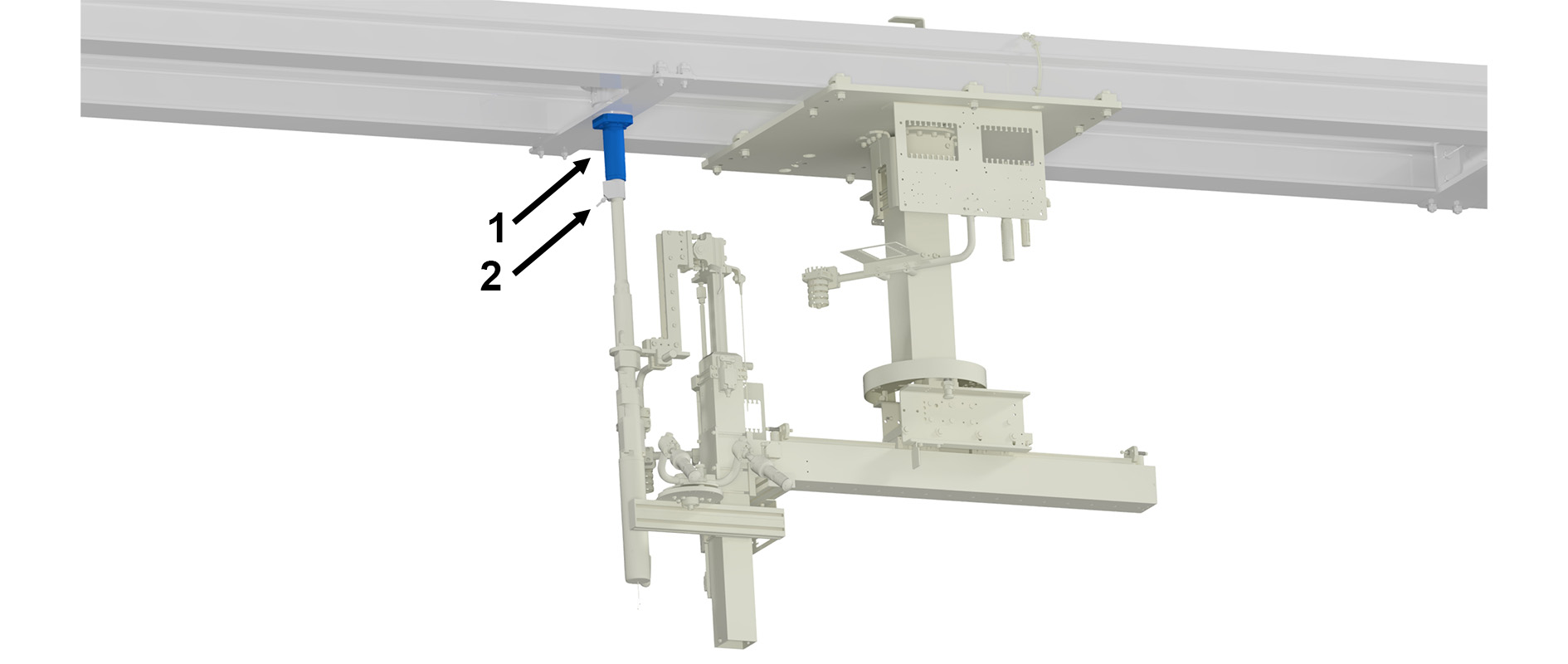

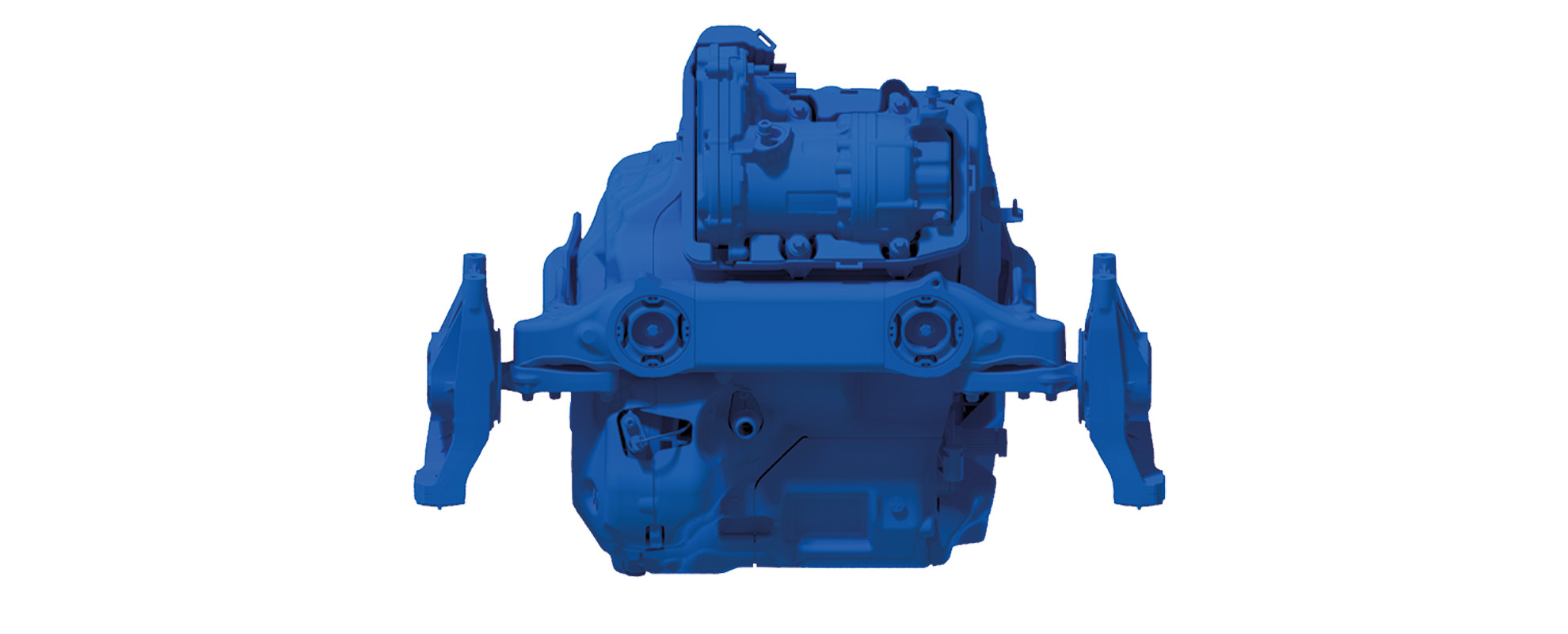

Reference measurement IN LINE, without removing the screw spindle

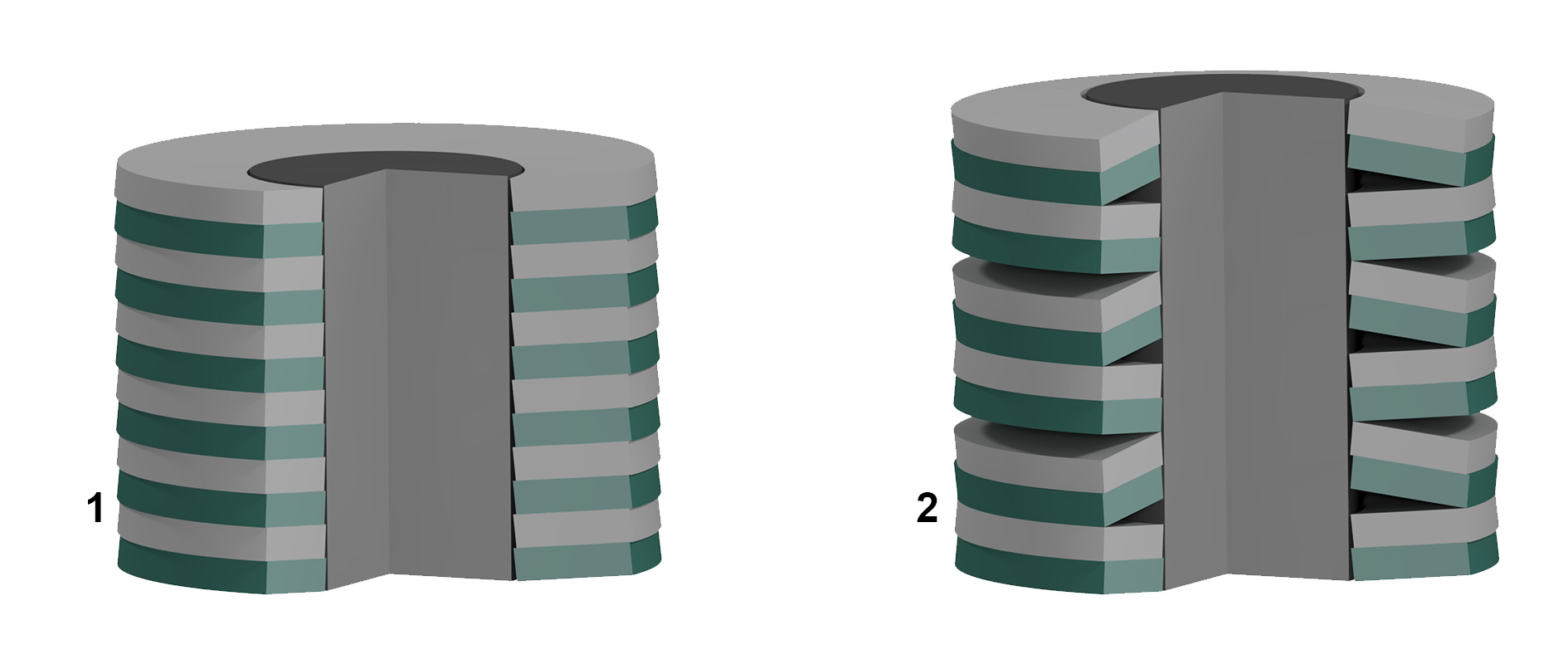

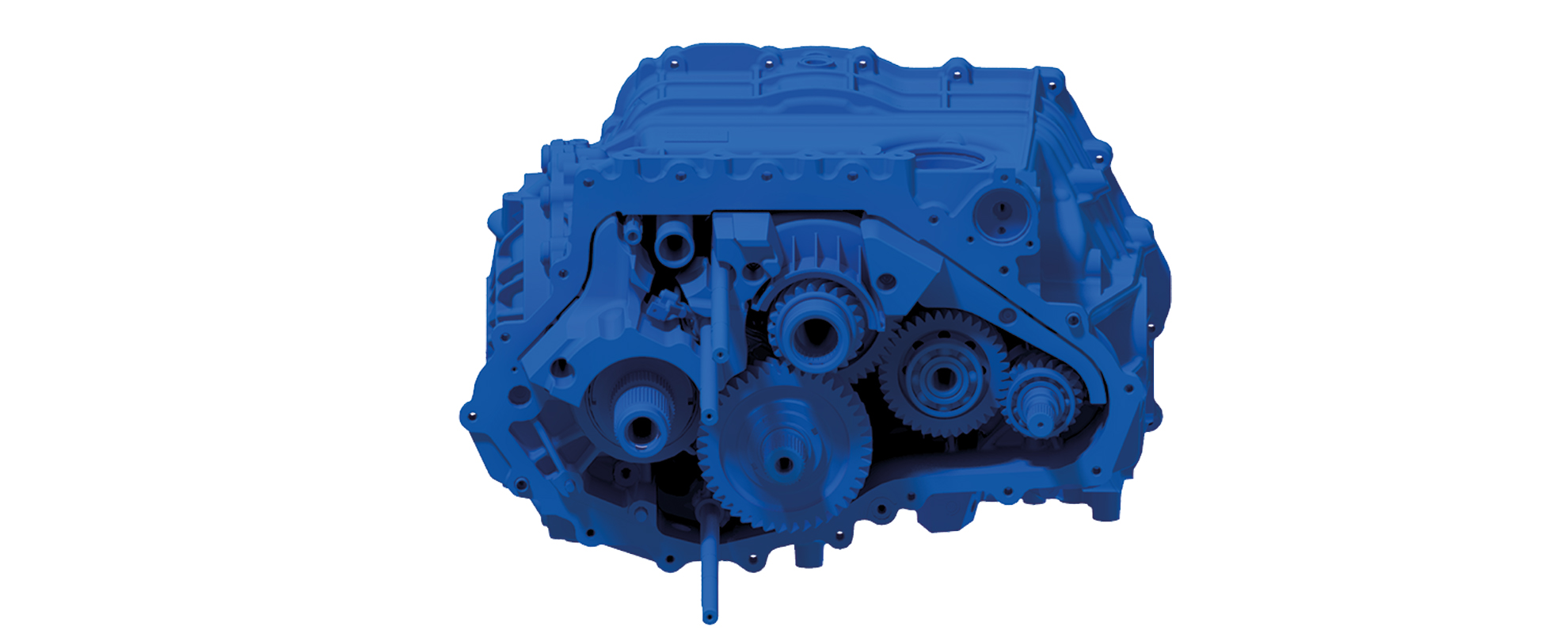

Approximate simulation of hard or soft screw cases through shifting of the disk spring assembly possible

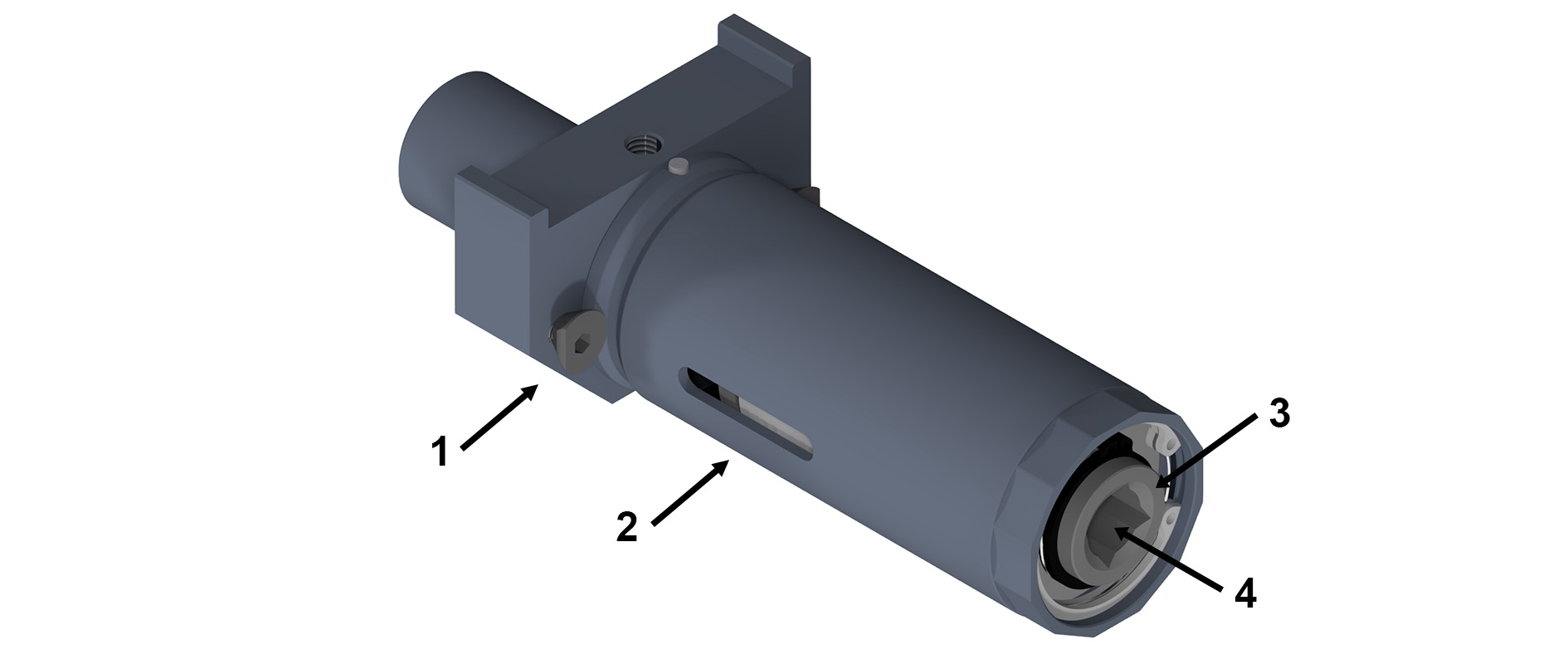

Suitable for angle of rotation and torque measurement

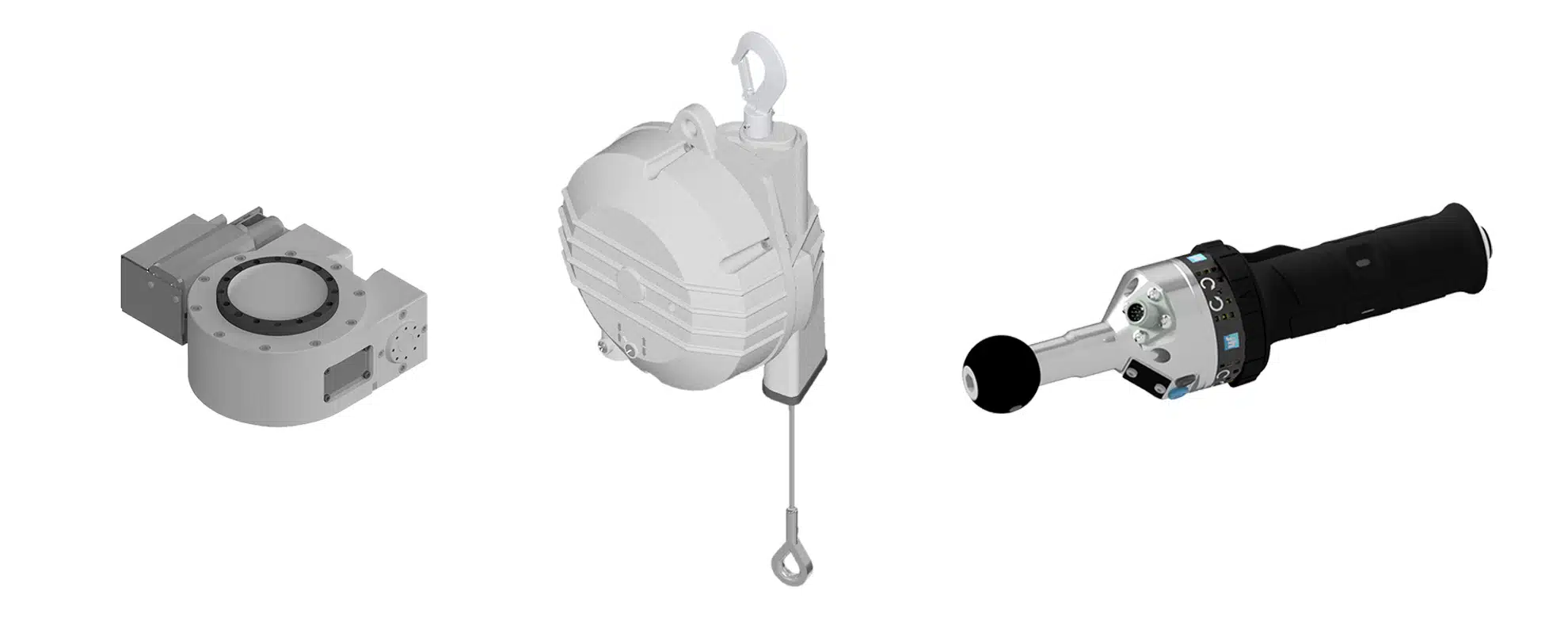

Suitable for installation spindles and handheld screwdrivers

Process integration & operational safety

Quick clamping system for spindle adaptation

Difference to the machine capability study (MFU)

Reference measurement

Purpose

Used to calibrate and ensure the accuracy of the spindle movements.

Frequency

Performed regularly to ensure precise positioning and force application of the spindle. guarantee.

Focus

Focuses on precise positioning and adherence to the specified tolerances for every screwdriving operation. screwing process.

MFU

Purpose

Evaluates the ability of a machine to consistently deliver high-quality results under real production conditions. deliver.

Frequency

Typically carried out at the start of a production run or after significant changes to the machine. carried out.

Focus

Analyzes the overall performance of the machine, including precision, repeatability and stability over time. over a longer period of time.

Summary

Reference measurement

Focuses on the short-term accuracy and calibration of a screwdriving spindle or a handheld screwdriver. handheld screwdriver.

Machine capability test

Evaluates the long-term performance and reliability of a machine under production conditions. production conditions.

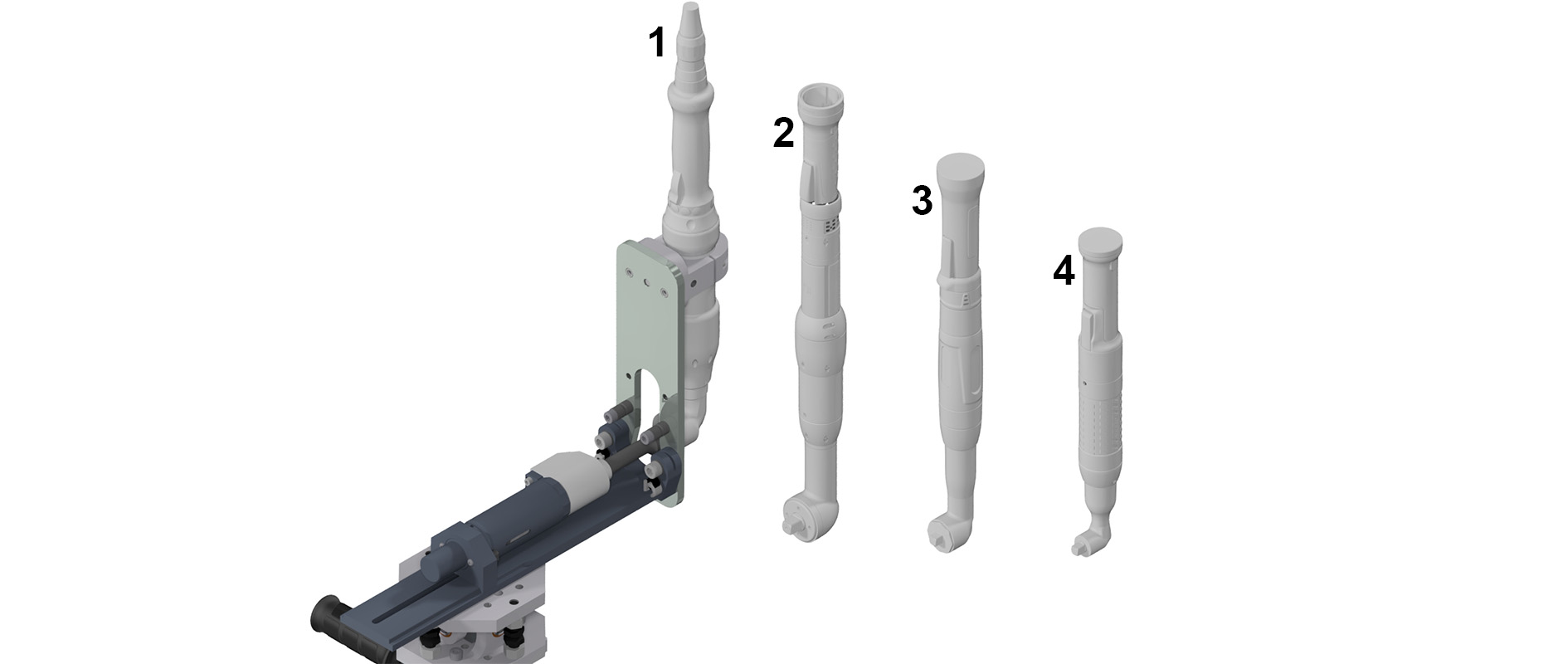

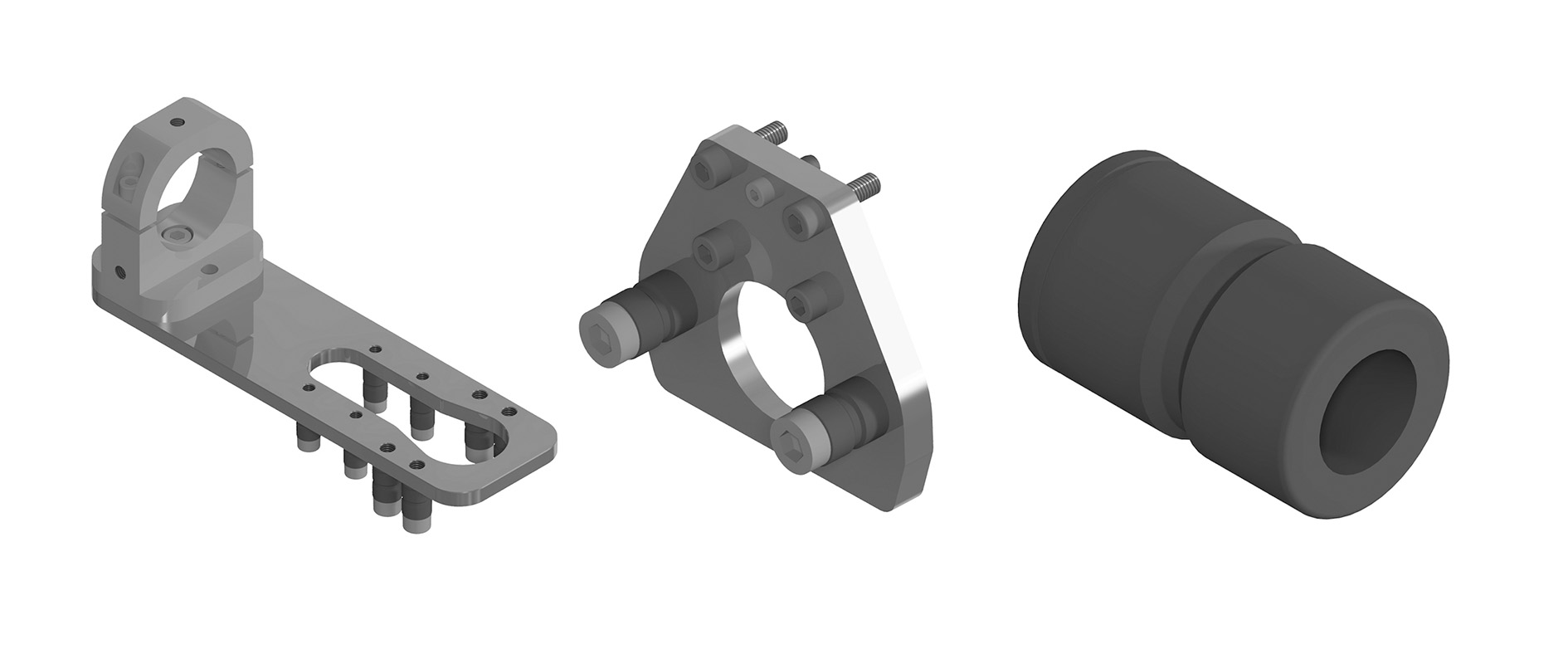

Variant overview

Reference measuring adapter screw mounting

Manufacturer